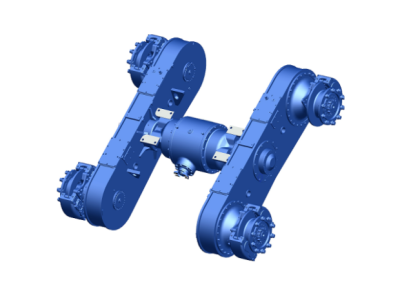

Underground Scraper Drive Axle

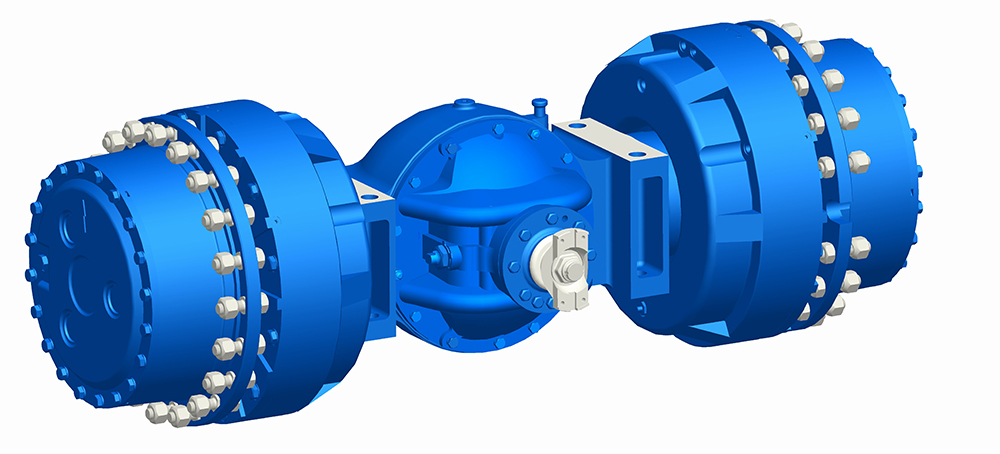

1.Using No-Spin LSD , 100% antiskid on muddy pavement.

2.Wheel using wet brake, driving brake and parking brake become one. Safe and reliable.

3.Wheel floating oil seal, more suitable for wet and muddy environment.

4.Key components purchase from world famous brand, long service life.

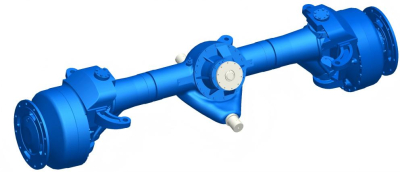

5.Steel casting axle house, more reasonable for two grades reduction transmission.

6. Suited for 2 cubic underground carry scrapers.

Introduction:

This equipment, designed for 2-cubic underground carry scrapers, incorporates multiple advanced features. It utilizes a No-Spin LSD to achieve 100% antiskid on muddy pavements. The wheels are equipped with wet brakes that integrate driving and parking functions, ensuring safety and reliability. With wheel floating oil seals, it's highly adaptable to wet and muddy environments. Key components sourced from world-renowned brands guarantee a long service life. Moreover, the steel casting axle house is optimized for two grades of reduction transmission, enhancing overall performance.

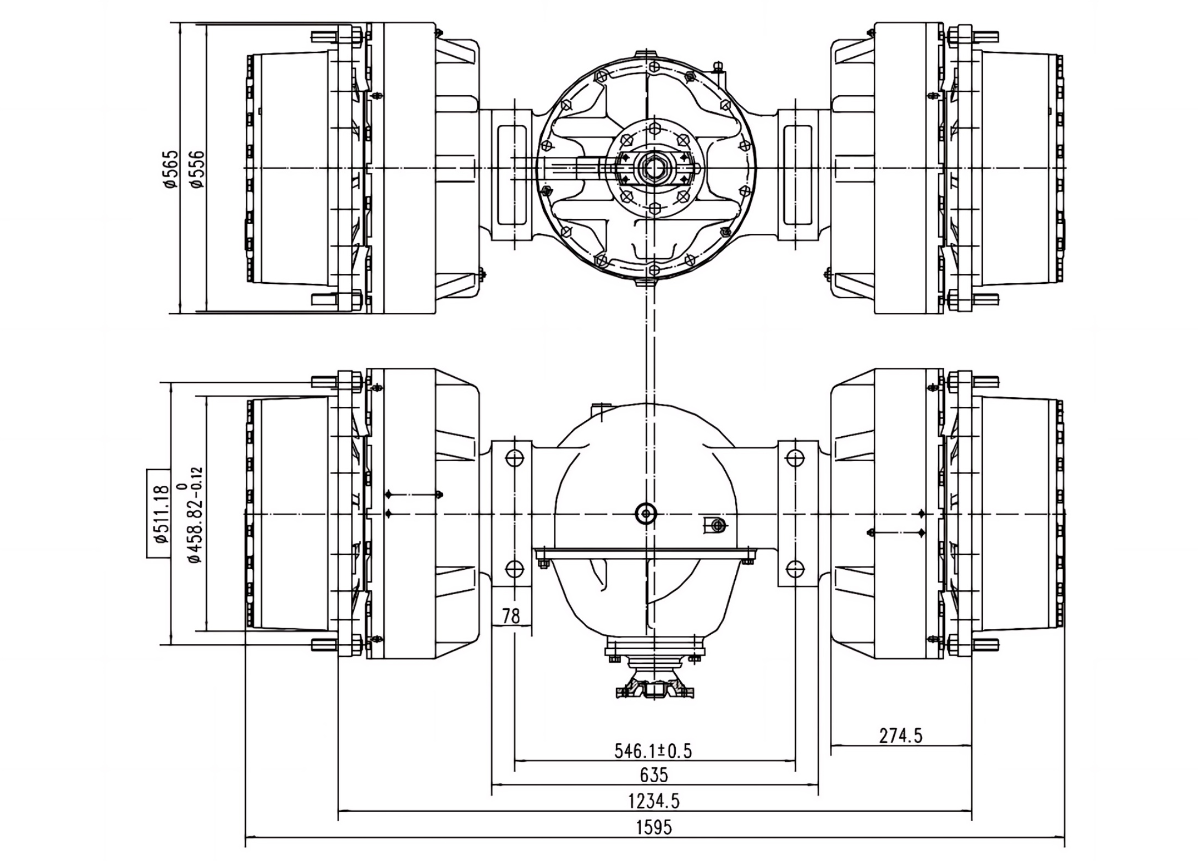

Main technical parameters:

Total transmission Ratio | 26.118 |

Maximum input torque | 2668N.m |

Theory maximum load | 18160Kg |

Brake structure | POSI-STOP Spring brake/hydraulic pine brake |

Starting oil pressure of stopping braking | 10.4MPa |

Single braking capacity | 163.9ml |

Single braking moment | 20000N.m |

Brake cooling oil and Remove the brake oil | L-HL46 hydraulic oil |

request for driving axle (API standard) | GL-5:85W/90 Gear Oil (above -12℃) |