Decoding How Lutong Drive Axles Became the "Power Anchor" of Engineering Machinery

Recently, the annual supplier conference of the Loader Business Unit of Sany Heavy Industry, a global leader in engineering machinery, concluded. Amid intense competition from numerous core component suppliers, Shandong Lutong Heavy Machinery Co., Ltd. stood out and was honored with the annual "Excellent Supplier" title, recognized for its outstanding technical capabilities, stable product quality, and efficient delivery service in the drive axle field. This recognition from the top of the industry carries far greater weight than a mere certificate. It not only affirms the efforts Shandong Lutong has made as a core strategic partner of Sany over the past years but also serves as a prism, clearly reflecting the transition of Chinese core component enterprises within the engineering machinery industry chain—shifting from being "supporting suppliers" to becoming "value co-creators." The foundation of this achievement lies in its proud and continuously evolving full series of loader drive axle products and its deep customized solution capabilities.

I. Behind the Honor: The Value Evolution from Stable Supply to Strategic Synergy

The title of "Excellent Supplier" represents the highest level of recognition within Sany's stringent supply chain evaluation system. Its selection criteria extend far beyond product on-time delivery rates and batch qualification rates, delving deep into comprehensive dimensions such as technological collaborative innovation capability, quality lifecycle management, cost-value contribution, and supply chain resilience in response to market fluctuations. Shandong Lutong's receipt of this honor signifies that the cooperation between both parties has transcended the traditional "procurement-supply" relationship and entered a phase of deep strategic synergy characterized by joint technology R&D, market co-expansion, and value sharing.

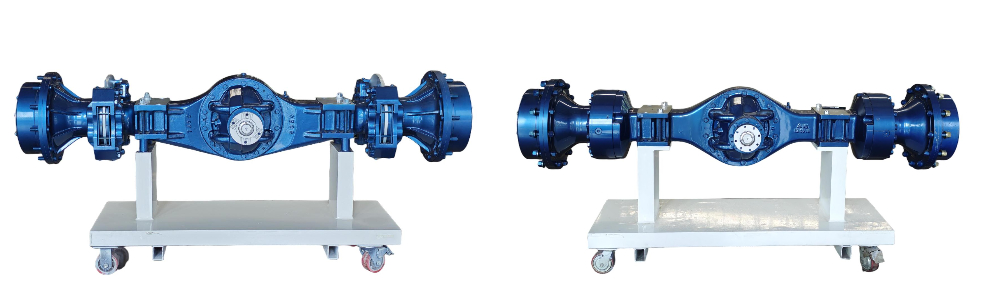

The establishment of this relationship stems from Shandong Lutong's precise insight into and proactive response to the core needs of the OEM. Sany's loader product line is extensive, ranging from small-to-medium models for municipal and farmland improvement projects to large and ultra-large models operating in mines and ports, involving vastly different working conditions. The loader drive axles provided by Shandong Lutong are far from a "one-size-fits-all" generic product; they constitute a highly flexible product matrix. Its core advantage is first reflected in exceptional platform compatibility and speed ratio diversity. Shandong Lutong's drive axle products offer multiple key connection dimensions and mounting interfaces, enabling seamless adaptation to multiple generations and tonnage platforms under the Sany brand. More importantly, the company provides various speed ratio configuration options, allowing the OEM to precisely optimize powertrain matching based on the typical duty cycles of target markets and engine characteristics, thereby helping the host machine achieve higher operational efficiency and superior fuel economy from the source.

Secondly, it is a reliability-driven design philosophy. Loaders operate in harsh environments where drive axles endure long-term impact loads and torsional loads. Oil leakage and abnormal wear are common industry pain points. Through continuous structural optimization and material innovation of its sealing systems, Shandong Lutong has achieved a drive axle leakage rate far below the industry average. This extreme pursuit of detail directly translates into higher terminal equipment availability and lower aftermarket maintenance costs—key factors for OEMs like Sany in building product reputation and customer loyalty in global market competition.

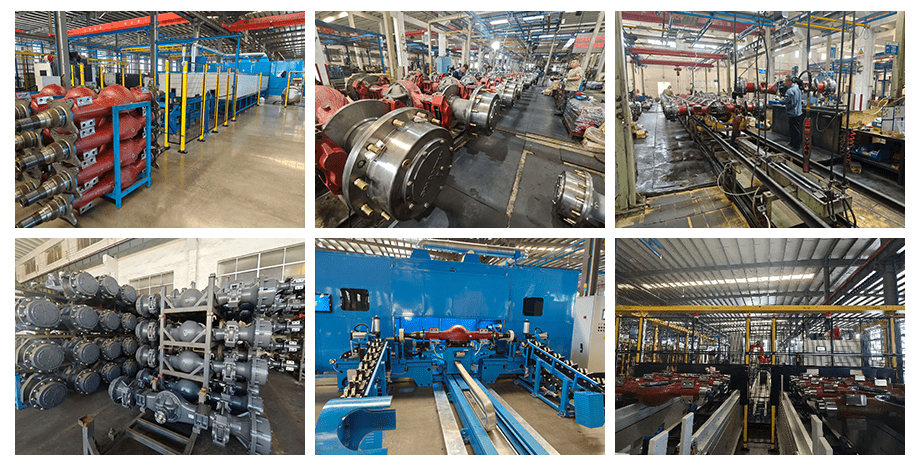

II. The Foundation of Intelligent Manufacturing: Robotic Production Lines and Digital Control Forge Consistent Quality

The acquisition of this honor is inseparable from robust and reliable manufacturing capability as its backbone. Entering Shandong Lutong's modern factory, intelligent production lines dedicated to the core components of loader drive axles operate efficiently. Here, the machining of key components such as axle housings, main reducer housings, planetary carriers, and differential carriers no longer relies on the traditional mode dependent on master craftsmen's skills but is led by automated units equipped with robots from internationally top-tier brands like ABB, FANUC, and KUKA.

These "iron arms," in coordination with precision CNC machine tools, complete a series of complex processes including milling, drilling, and tapping. Their repetitive positioning accuracy reaches the micrometer level, fundamentally eliminating quality fluctuations caused by human factors. Intelligent production lines signify not only higher production efficiency and cost controllability but, most crucially, deliver the core value of achieving ultimate consistency in product quality. The critical dimensions and geometric tolerances of every workpiece coming off the line are locked within the narrow range set by the digital program, laying an impeccable foundation for subsequent high-precision assembly.

The assembly phase is another "precision surgery." On the dedicated loader drive axle assembly line, custom fixtures ensure that all components of the assembly remain in their theoretically designed positions throughout the process. Highly standardized assembly procedures minimize human assembly errors, ensuring every delivered drive axle possesses the same excellent genes—longer service life, lower operating noise and vibration, and outstanding reliability from the moment it leaves the factory. From raw material intake to finished product off the line, full-process quality data is collected, monitored, and analyzed in real-time, forming a traceable digital quality archive. This provides a data-driven scientific basis for continuous process optimization and quality improvement.

III. Product Evolution: A Dual-Driven Future by Electrification and High-End Development

Facing the irreversible waves of electrification and intelligence in the engineering machinery industry, Shandong Lutong is not content with its advantages in traditional fields. Instead, with forward-looking planning, it has launched drive solutions specifically tailored for electric loaders. It has given profound consideration to the characteristics of electric drive systems, such as high torque, fast response, and the need for energy recovery, and has comprehensively optimized the structure accordingly.

The electric loader drive axle adopts an efficient NGW planetary gear reduction structure, achieving a wide speed ratio range and strong load capacity within a compact space. Its transmission system is specially designed to be highly compatible with motor characteristics, aiming to maximize transmission efficiency and thereby extend battery life. The braking system is also upgraded for electrification scenarios, utilizing large-torque disc-caliper brakes for rapid response, and considers synergy with motor braking for energy recovery to enhance overall energy efficiency. This deeply customized electric loader drive axle is no longer an independent component but an inseparable, optimized core module of the electric loader's power system, truly helping OEMs unlock the performance potential of electric equipment.

Simultaneously, in the high-end market, Shandong Lutong strongly promotes loader drive axles equipped with wet brake systems. For equipment operating in heavy-duty, high-frequency, long downhill conditions such as mining, tunneling, and large-scale infrastructure construction, thermal fade and failure of the braking system pose significant safety hazards. Wet brake technology completely encloses multiple brake friction pairs within a cavity filled with cooling oil. The braking torque it generates is far greater than that of traditional dry brakes, and its performance is extremely stable. Under continuous downhill operation, its excellent heat dissipation capability results in virtually no thermal fade, ensuring sustained braking force. Crucially, the fully enclosed oil-bath design completely eliminates brake sparks, providing an intrinsically safe solution for flammable and explosive environments like underground coal mines and petrochemical sites. Additionally, the lubricating effect of the oil causes extremely slow brake lining wear, significantly extending maintenance intervals, reducing total lifecycle costs, making it the "preferred configuration" for high-end customers pursuing safe, efficient, and low-maintenance operations.

IV. System Empowerment: The Supply Chain Role Evolving from Stable Delivery to Ecosystem Co-creation

The honor of "Excellent Supplier" also affirms Shandong Lutong's strong supply chain service capability. In today's uncertain global market environment, stable supply capability itself is a scarce strategic resource. Leveraging scientific capacity planning and raw material reserves, Shandong Lutong has established sufficient stocks of finished products and key components. This enables rapid response to fluctuations in OEM production plans and urgent orders, ensuring the timeliness and accuracy of deliveries. This capability greatly enhances the supply chain resilience of OEMs like Sany in responding to market demand changes and securing project timelines.

Deeper service is reflected in the front-loading and coordination of technical support. Shandong Lutong's engineering team engages early in the OEM's new product development process. Based on a rich application database and simulation analysis capabilities, they provide drive axle selection and matching optimization suggestions, jointly solving challenges in powertrain layout. From renowned domestic and international enterprises like Sany, Shantui, Lovol, Taiyuan Heavy Industry Group, Borelton, Hyundai, and DEVELON, extensive cooperation has allowed Shandong Lutong to accumulate profound cross-brand, cross-scenario application knowledge. This knowledge feeds back into continuous product improvement and enables more targeted solutions for new and existing clients, forming a virtuous cycle of "application-improvement-reapplication."

V. Future Outlook: Building New Heights for Chinese Manufacturing through Core Component Innovation

Receiving Sany's "Excellent Supplier" award is a milestone and, more importantly, a new starting point. It signifies that Shandong Lutong's position as a Chinese core high-end component manufacturer has received authoritative market certification. Looking ahead, competition in the engineering machinery industry will increasingly focus on the overall efficiency of the industry chain, the full lifecycle value of products, and the implementation speed of green and intelligent technologies.

Shandong Lutong will continue to adhere to the philosophy of "Technology Led, Quality as the Foundation, Customer First," deepening its efforts in the following directions: First, continuously deepen technological iteration in mature products like the loader drive axle, pursuing limits in lightweight design, noise control, and transmission efficiency. Second, fully embrace electrification, develop more integrated and intelligent electric drive systems, and co-build an open cooperation ecosystem with OEMs, battery, and motor enterprises. Third, promote high-end technologies like wet brake systems to more product lines, providing safety upgrades for a broader range of engineering machinery. Fourth, strengthen digital factory and supply chain system construction, aiming to become a trusted "Power Partner" for global OEM clients with more transparent, agile, and reliable supply services.

Standing at the historical juncture where Chinese engineering machinery is transitioning from scale leadership to technological leadership, outstanding core component enterprises represented by Shandong Lutong are providing a continuous stream of "core" power for the upgrade and breakthrough of host machine products with their solid innovation capabilities and excellent manufacturing standards. Together with OEMs, they are forging not only robust and durable equipment but also increasingly prominent value credentials for "Made in China" in the global market.