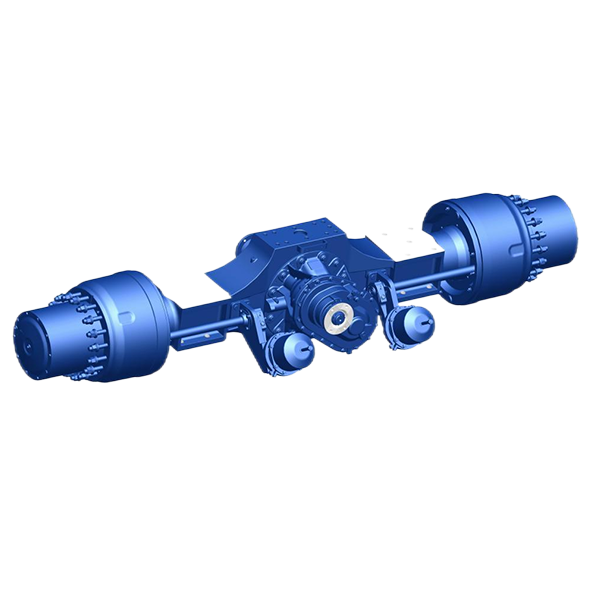

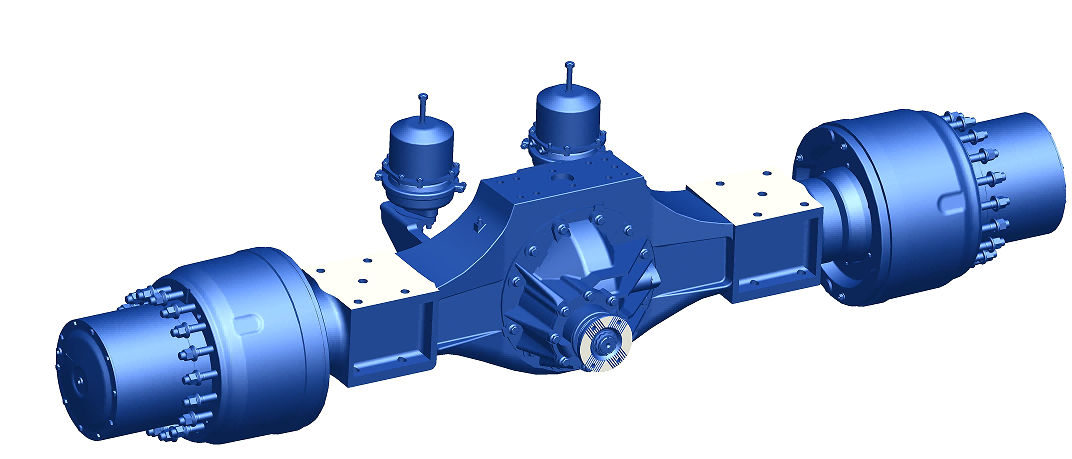

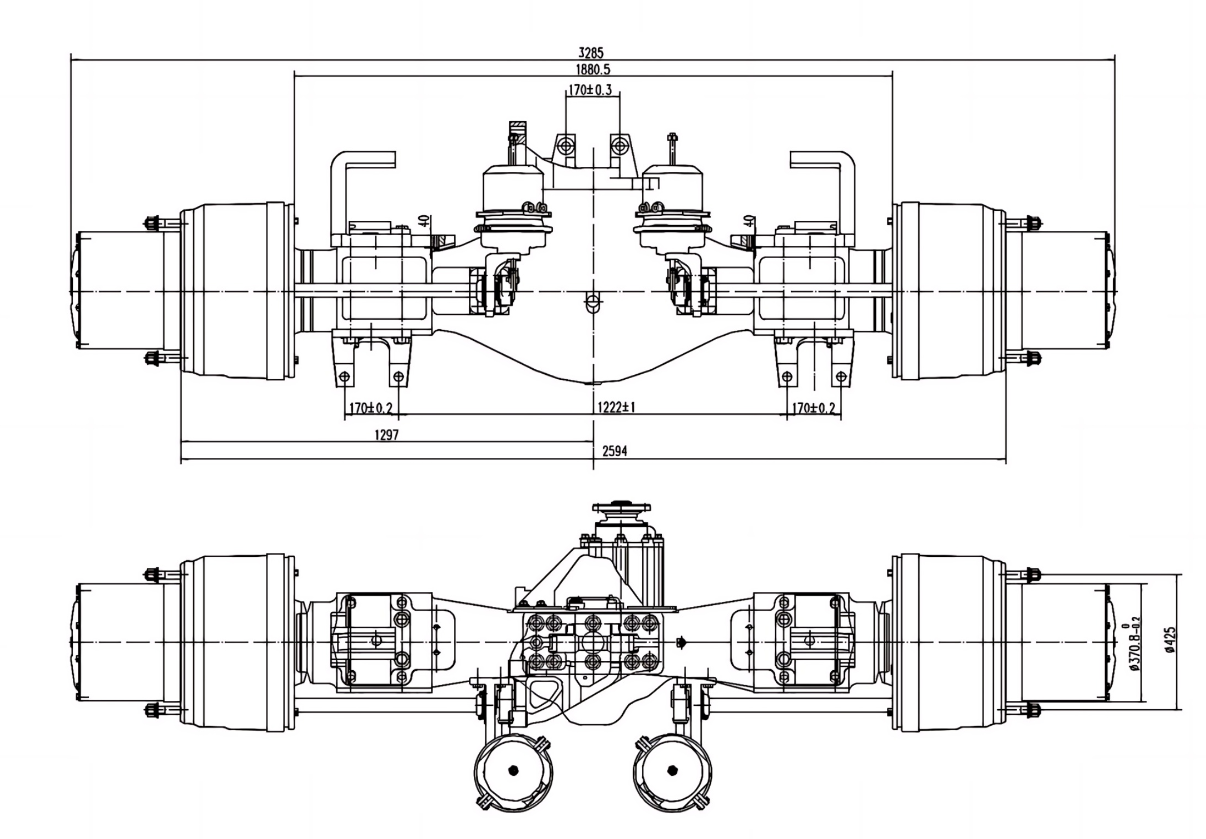

Axle Of 40 Ton Mining Truck

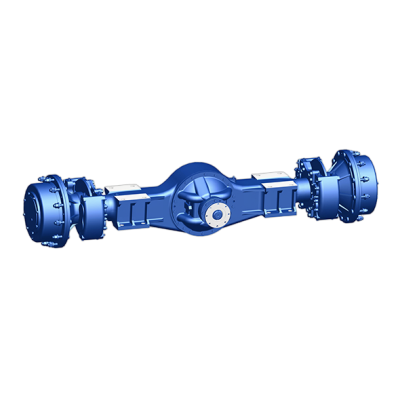

1. The final drive uses constant-height spiral bevel gears for high-efficiency, low-noise transmission

2. Wheel-mounted planetary reduction design – compact, smooth, and reliably stable output

3. One-piece cast steel axle housing – high load capacity, excellent rigidity

4. Utilizes internally expanding double shoe normally closed brakes for stable, reliable parking

5. Equipped with inter-axle differential lock for excellent traction on muddy and slippery terrain.

6.Usually installed on 105-ton wide - body mining trucks

Introduction:

Designed for wide-body mining trucks and heavy machinery. The one-piece cast steel axle housing integrates a final drive with constant-height spiral bevel gears and wheel-mounted NGW-type planetary reduction gearing. An internally expanding double shoe normally closed brake system provides combined service and parking braking. Power is delivered to the rear axle via a through-shaft transmission with inter-axle differential lock.These technical solutions enhance load capacity and reliability, ensuring the product withstands harsh mining conditions

Main technical parameters:

Overall gear ratio | 16.641 |

Maximum input torque | 20400N.m |

Rated load | 40000Kg |

Brake specifications | Φ500×250 |

Brake chamber specifications | 36/30 |

Brake air pressure | 0.8MPa |

Overall axle braking torque | 90000N.m |

Drive axle lubrication requirements | GL-5:85W/90 Gear Oil (above -12 ℃) |

Maintenance

For construction machinery axle maintenance, the principle of "prevention-oriented, enforced maintenance" should be followed. Through regular cleaning, scheduled lubrication, tightening, and part examinations, latent problems can be spotted and resolved in a timely manner, stopping minor issues from turning into significant failures—such as bearing seizures resulting in gear tooth damage or axle breaks. It is advised to create a tailored maintenance schedule based on how often the equipment is used and its operating conditions, and prioritize using OEM components to maintain stable axle performance and extend the equipment’s lifespan.