Caterpillar Enters Wide-Body Mining Trucks: The Rise of Chinese Drive Axle Solutions

The landscape of the global mining equipment sector is experiencing new ripples due to a significant announcement. Recently, industry giant Caterpillar officially launched its first 70-ton class 707 off-highway wide-body dump truck bearing the "Cat" brand into emerging markets. This move is far more than a simple product line extension; it is perceived as a strong market signal: the strategic value of the Wide-Body Dump Truck (WBDT) segment—once regarded as "non-mainstream" by some international giants—has now received formal endorsement from a top global player. Caterpillar's high-profile entry with a dual-brand (Cat and SEM) strategy not only validates the global commercial success of the "wide-body mining truck" model pioneered by Chinese engineering machinery enterprises but also indicates that technological competition in this field will rapidly extend from overall machine integration to deeper contests involving core components like drive systems and electronic control systems. In this industry transformation led by giants, a high-performance, highly reliable Wide-Body Mining Truck Drive Axle Assembly is becoming the core differentiator determining equipment availability, operating costs, and safety performance.

I. The Giant's Pivot: A Reshaping of the Global Mining Truck Landscape Driven by Market Demand

Caterpillar's decision is a direct response to market data. Over the past decade, wide-body dump trucks originating from China's engineering machinery industry have emerged prominently in the global short-to-medium haul mine transport market, thanks to their excellent cost-performance ratio, flexible scenario adaptability, and continuously increasing payload capacity. Industry data shows that during peak periods, annual sales of Chinese wide-body dump trucks exceeded 25,000 units, with global annual demand projected to climb to 33,000 units by 2030. In contrast, global annual demand for traditional mining rigid dump trucks remains stable at around 4,000 units. This trend of "one rising, the other declining" is particularly evident in sub-100-ton transport scenarios, where wide-body trucks have substantively impacted and replaced a portion of the market share of traditional articulated trucks and smaller rigid trucks.

More critically, Chinese brands represented by Lingong, Tongli, XCMG, and Sany are no longer content with domestic success and are accelerating their overseas deployment with highly competitive products. In emerging resource markets across Southeast Asia, Africa, Central Asia, and South America, Chinese wide-body mining trucks have gained favor with numerous mining clients due to their lower Total Cost of Ownership (TCO) and increasingly enhanced reliability. This undoubtedly affects the foundation of international giants like Caterpillar and Komatsu in these key growth markets. Therefore, Caterpillar's launch of the 707 is not only about capturing a share of a new market but is also a strategic necessity to defend market share and maintain the stability of its global customer network. Its use of an "Integrated Cat Powertrain," "remanufacturable C13 engine," and triple-brake safety system all directly respond to the core strengths of Chinese brands—high cost-performance and high reliability. This competition is destined, from the outset, to be comprehensive and in-depth.

II. The Technological High Ground: The Extreme Performance Demands on Wide-Body Mining Truck Drive Axles

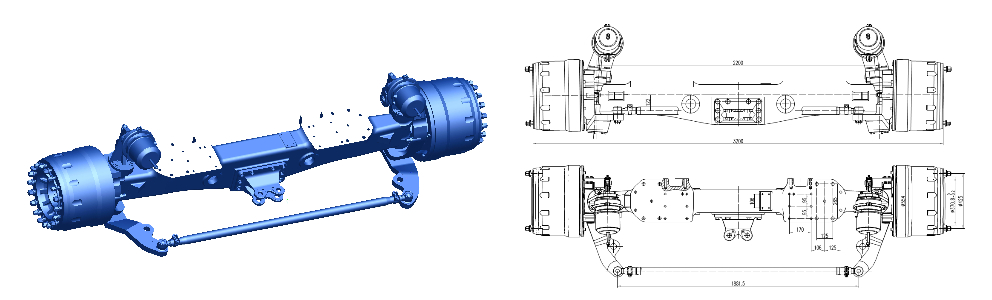

While industry focus converges on complete machine brands and market strategies, experienced mining equipment managers understand that a machine's long-term performance depends on those core systems hidden beneath the frame. Among these, the Drive Axle Assembly, serving as the terminal for power transmission, load-bearing, and execution, directly defines the vehicle's traction, mobility, durability, and safety limits. A complete set of Wide-Body Mining Truck Drive Axles typically includes a steering front axle, a through-drive axle (mid-axle), and a rear axle. Under complex mining conditions, they collectively face unprecedented challenges:

Extreme Loads & Sustained Impact: The shock loads from hauling heavy loads downhill and navigating bumpy haul roads far exceed the design scope for on-road vehicles, presenting the first major test for the axle housing's structural strength and fatigue life.

All-Weather Harsh Environment: Persistent assault from high dust, slurry, and extreme temperature swings (from equatorial heat to plateau cold) demands exceptional sealing performance and environmental adaptability from the drive system.

Intelligent Power Distribution on Complex Terrain: On muddy, loose, or unevenly graded roads, the key to improving mobility and efficiency lies in instantly locking torque to the axle with traction, preventing power loss and tire spin.

III. The Chinese Solution: Forging Core Drive Axle Strength Through Deep Engineering Innovation

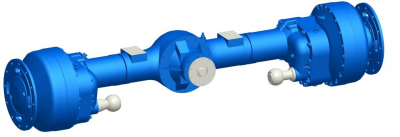

Facing the high standards required to compete on the same stage as global giants, our company, relying on decades of deep cultivation in the heavy-duty drive axle field, has launched a new generation of high-performance Wide-Body Mining Truck Drive Axle Assemblies. Our R&D philosophy is not simple benchmarking but involves systematic forward development—from materials to structure, from transmission to control—based on a profound understanding of mining operations.

1. The Steel Backbone: The Art of Axle Housing through Topology Optimization and Ultimate Validation

The axle housing is the foundation of the drive axle. We abandon generic designs, adopting Finite Element Analysis (FEA)-based topology optimization technology to repeatedly "temper" the housing structure in the virtual world, allowing material to distribute like growing bones along critical load paths. We select high-strength special steel, supplemented by advanced precision casting and controlled heat treatment processes, granting the housing very high yield strength while maintaining excellent toughness. Every housing design must pass a bench test involving over a million vertical bending fatigue cycles, far exceeding industry standards. This stringent test simulates several times the bumps and impacts a vehicle might endure over its entire lifespan under actual conditions. The goal is singular: to eliminate potential failures due to structural fatigue at the source, laying an unshakable foundation for overall machine safety.

2. The Power Heart: Precision Transmission and Intelligent Torque Management

The gear transmission system of the through-drive and rear axles is the core of efficient power conversion. We employ advanced gear design software and simulation tools to optimize tooth profiles and meshing parameters, and utilize cutting-edge equipment like high-precision CNC gear grinders for manufacturing, ensuring gear accuracy reaches industry-leading levels. This results in smoother transmission, lower noise, and longer service life.

More critical is the torque management capability for complex road conditions. Our drive axles are equipped with a responsive inter-axle differential locking system. When the system detects loss of traction at one axle (e.g., mid or rear) due to wheel slip, it can quickly lock the inter-axle differential, forcibly transferring engine torque almost without loss to the axle(s) still with grip. This "intelligent" power redistribution capability ensures the vehicle still receives ample traction even in conditions most prone to getting stuck, such as mud or on slopes, greatly enhancing availability and operational efficiency.

3. The All-Weather Fortress: Proactive Sealing Defense and Efficient Thermal Management

The mining environment presents the ultimate test for drive axle sealing. We have constructed a multi-barrier "proactive + passive" sealing protection system. At critical points like axle ends and mating surfaces, we employ combinations of multi-lip seals and O-rings, coupled with uniquely designed anti-dust labyrinth structures, creating layer upon layer of defense that effectively blocks the ingress paths of dust and slurry, protecting internal precision gears and bearings.

Addressing the thermal loads from braking during continuous heavy-load downhill hauls and the inherent heat generation of the transmission system, we have optimized the internal lubrication channels of the axle housing and increased the heat dissipation area in key zones through Computational Fluid Dynamics (CFD) simulation. This efficient thermal management system ensures that the internal lubricant temperature of the drive axle always remains within the optimal operating window during prolonged, high-load extreme operation, preventing lubrication failure and rapid component wear caused by high-temperature oil oxidation and sudden viscosity drops.

IV. Collaborative Evolution: Providing Core Support for "Chinese-Style Innovation" and "Global Giants' Initiatives"

Caterpillar's 707 entry, alongside new technology applications from Chinese brands like the XCMG XDR80TE all-electric mining truck (e.g., electrification, autonomous driving), jointly point to two major future trends for wide-body mining trucks: green intelligence and high lifecycle value. This places new demands on drive axles.

Our technological platform is prepared for this. Modular design enables better integration of the drive axle with electric drive systems, providing a reliable mobility foundation for new energy mining trucks. Simultaneously, we are developing new intelligent drive axles with integrated sensors capable of real-time monitoring of status data like load, temperature, and vibration. This provides data interfaces for predictive maintenance and integration into vehicle intelligent operation and maintenance systems, aligning with Caterpillar's emphasized digital strategy of "increasing services revenue."

Whether serving high-end models from Chinese brands going global, supporting continuously upgraded domestic products in response to international competition, or offering a high-quality option for the supply chains of giants like Caterpillar, we provide not just a component but a core mobility solution aimed at reducing total lifecycle operating costs and enhancing equipment availability. Our goal is to become the trusted "power cornerstone" for global mining equipment manufacturers, enhancing their product competitiveness in intense market battles.

V. Conclusion: Anchoring Core Value Amidst Transformation

Caterpillar's entry into the wide-body mining truck arena is a milestone for industry development. It declares the transition of wide-body mining trucks from a "Chinese phenomenon" to a "global standard" and signals that competition will enter a deep-water zone focused on core technology, total cost, and service quality. In this upgrade wave led by giants, the drive axle—as the core hub connecting power to the ground and bearing safety and efficiency—will see its technological connotation and value unprecedentedly emphasized.

We firmly believe that only through continuous exploration in materials science, extremely rigorous precision manufacturing, and an unwavering reverence for mining operating conditions can we forge drive axle products that truly withstand the test of time and extreme environments. It is with this "engineering spirit" that we provide stable and powerful mobility for this era filled with transformation and opportunity, driving mine haulage towards a more efficient, safer, and sustainable future together with global customers and partners.