The Journey of China's First Logger Drive Axle

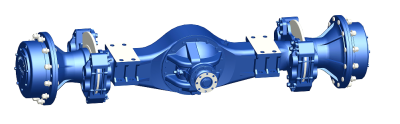

In the forestry machinery sector, timber harvesters have long stood as a "hidden peak" in the localization process due to their high technological content and added value. For a long time, China's market for logging equipment has relied mainly on imports or modifications from excavators. The core technology of dedicated timber harvesters—particularly the drive axle systems designed for extreme mountainous operating conditions—has remained a barrier difficult for domestic OEMs to overcome. However, this situation is quietly changing. Shandong Lutong, leveraging over three decades of expertise in drive axle manufacturing, has successfully developed China's first high-performance drive axle specifically designed for timber harvesters after years of R&D and validation. This breakthrough not only achieves localization of key components but has also attracted close attention and orders from domestic and international OEMs, thanks to its exceptional sealing, reliability, and off-road capability. This article takes an in-depth look, through the lens of the production floor, at the entire process of this drive axle—from design to vehicle testing—showcasing the steady progress of Chinese manufacturing in the field of high-end transmission components.

I. The Challenge in a Niche Field: Why Are Logger Drive Axles So Difficult to Manufacture?

Timber harvesters are not a widely recognized category of machinery. In China, due to the complexity of their front hydraulic work devices and chassis transmission systems, high vehicle costs, and the predominantly mountainous terrain that limits the applicability of traditional large logging equipment, this market has long been dominated by foreign brands, making it a typical "niche" high-end equipment sector. However, niche does not mean absence of demand. As domestic OEMs accelerate their expansion into overseas markets, the need for specialized equipment suitable for forestry-rich regions such as Northern Europe, Russia, and North America is becoming increasingly apparent. The working conditions for timber harvesters are often extremely harsh: rugged mountainous terrain, damp and muddy forest floors, and continuous heavy-load logging operations pose extreme challenges to the machine's power, mobility, sealing, and reliability. Among these, the drive axle—as the core chassis component that supports the vehicle's weight, transmits drive torque, and enables steering and braking—directly determines the machine's survivability under extreme conditions. Inadequate sealing can allow mud and water intrusion, accelerating wear on gears and bearings; insufficient rigidity or poor design can lead to structural damage or vehicle instability on rough terrain; and unreliable braking performance can directly threaten operator safety. Precisely for these reasons, a specialized drive axle capable of handling mountainous logging conditions has become a technological fortress that domestic OEMs must conquer to enter this segment. It was after recognizing this latent market demand and technological gap that Shandong Lutong resolutely initiated its independent R&D project for logger drive axles.

II. The Path to Breakthrough: Three Decades of Experience Empowering Solutions to Design and Process Challenges

From the outset of the R&D process, Shandong Lutong's technical team clearly understood that simply replicating traditional construction machinery drive axle designs would not suffice. They systematically studied the design philosophies of advanced similar products globally and conducted multiple on-site investigations at OEM facilities and potential job sites to understand the actual working cycles and load profiles of timber harvesters. Drawing on over thirty years of experience in drive axle design and manufacturing, the team focused their breakthrough efforts on several core dimensions: extreme terrain adaptability, efficient and reliable transmission systems, and long-term sealing protection.

First, in the axle housing structural design, they innovatively adopted a balanced box oscillating structure. This design was not a simple imitation but was refined through detailed mechanical calculations and simulation analysis. The balanced box allows the left and right wheels to oscillate independently on uneven ground, maximizing tire contact area. Even on steep slopes, multiple tires maintain effective ground contact, providing sufficient traction and significantly enhancing vehicle stability and anti-rollover capability. More critically, the team engineered a scientific offset between the input center and output center of the balanced box. This detail ensures smoother transmission during traversal over undulating roads and obstacles, reduces motion interference, and markedly improves mobility.

Second, the internal transmission system employs entirely high-precision gears and planetary gear drives. Transmission components such as gears and half-shafts undergo carburizing, quenching, and precision grinding to ensure surface hardness, contact accuracy, and smooth power transmission. The internal transmission path is optimized to minimize power loss, achieving higher efficiency, lower noise, and longer service life.

Confronted with the harsh environments of mountainous forest areas—characterized by abundant water, dust, and corrosive media—sealing performance was elevated to an unprecedented strategic priority. The drive axle incorporates multi-layer composite sealing structures at all critical points: wheel ends, main reducer mating surfaces, balanced box articulation points, etc. The selected sealing materials balance oil resistance, high-low temperature tolerance, wear resistance, and anti-aging properties. Strict sealing inspection procedures during assembly ensure every gap is reliably sealed, preventing ingress of external contaminants.

Furthermore, as a crucial safety feature, this drive axle comes standard with a wet multi-disc brake. Compared to traditional dry brakes, the wet brake is fully immersed in cooling oil, offering excellent heat dissipation and strong resistance to thermal fade. This makes it particularly suitable for the prolonged, heavy-load downhill braking conditions typical of timber harvesting, ensuring stable and reliable braking performance. Additionally, the inclusion of an inter-wheel differential lock allows quick locking of the differential when one wheel slips, transferring power to the wheel with traction to facilitate easy extrication.

III. From Lab to Forest: Rigorous Testing Forges Reliable Quality

Passing bench tests was only the first step in product validation. Shandong Lutong understood that the real test lies in practical application. Therefore, the technical team proactively sought partnerships and sent the first batch of prototype drive axles to authoritative institutions such as the National Construction Machinery Quality Supervision and Inspection Center for more systematic and standardized mandatory bench testing. These tests strictly followed national standards and the industry's most stringent technical conditions, comprehensively evaluating the axle housing's vertical bending fatigue strength, static torsional strength, gear fatigue life, and brake comprehensive performance. When the test reports were stamped "qualified," the team gained initial confidence.

However, "knowledge from paper is ultimately shallow." To obtain the most authentic operational data, the company invested significantly in delivering the product to OEMs for real vehicle testing. In typical forestry environments like the cold regions of Northeast China and the mountainous areas of the Southwest, prototype machines equipped with Shandong Lutong's logger drive axles underwent six months of extreme condition testing. Test content included: prolonged heavy-load climbing, wading through swampy areas, rapid transit over bumpy harvested land, and continuous cycles of grabbing and cutting timber… Test personnel recorded the drive axle's performance under various extreme conditions, including oil temperature, leakage, brake response, and gear noise. Throughout, engineering teams were stationed on-site, monitoring data in real time and swiftly analyzing and addressing minor issues. Six months of exposure to wind, rain, and extreme abuse proved the drive axle's reliability, durability, and environmental adaptability, ultimately earning high praise from the OEM's testing team. It was this validation report based on real-world scenarios that paved the way for mass production.

IV. Market Response and Future Outlook: A New Benchmark for Domestic Core Components

A rigorous R&D approach, solid manufacturing processes, and "self-imposed" testing procedures collectively shaped the market competitiveness of Shandong Lutong's logger drive axle. When officially launched, it quickly garnered industry attention. First, it broke the long-standing reliance on imports or modifications in this field, proving that domestic enterprises are fully capable of overcoming technical barriers in high-end transmission components. Second, Shandong Lutong's pragmatic approach of "validate first, promote later" greatly enhanced OEMs' trust. They saw not just a product, but a complete, reliable technical solution and quality assurance system.

Currently, Shandong Lutong has successfully achieved stable small-batch supply to domestic OEMs pioneering in forestry machinery, such as Jining Jiubang, with positive feedback from actual use. More encouragingly, new OEM partnerships are under negotiation, indicating steadily expanding market acceptance. Moreover, the window to the international market has opened: after detailed evaluation of technical documentation and test reports, a Russian client has expressed clear intent to collaborate and is currently awaiting sample axles for vehicle testing, laying a solid foundation for the company's global expansion.

The production journey of the logger drive axle documented here not only records the birth of a product but also reflects the long-term commitment of a Chinese manufacturing enterprise to technological innovation, deep cultivation of niche markets, and establishing its reputation on reliability. Against the backdrop of global competition and the push for supply chain autonomy, Shandong Lutong's breakthrough in the "niche" field of logger drive axles holds significant demonstrative value. It signals that in countless specialized technical domains, Chinese manufacturing is quietly transitioning from follower to parallel runner, and even leader.

Looking ahead, Shandong Lutong will continue to focus on drive axles as its core, sustaining R&D investment, deepening collaboration with OEMs, further optimizing product performance for different regional and tree species logging conditions, and exploring possibilities for intelligent and electric drive applications in forestry machinery. This drive axle, journeying from precision workshops to the world's forests, carries not only the power of machinery but also the steadfast conviction of China's high-end equipment manufacturing industry in its upward breakthrough.