What is a Truck Axle?

In the operational system of commercial vehicles such as trucks, the truck axle is a core component responsible for multiple critical tasks including load bearing, driving, steering, and braking. It is often referred to as the vehicle’s “skeletal support” and “power transmission hub.” Simply put, the truck axle is the central shaft that connects the wheels and transmits power. Its functions cover the entire vehicle operation process: various loads generated during driving—including the vehicle’s own weight, cargo weight, as well as impact and braking forces—are evenly distributed through the axle to the wheels and then transferred to the ground, preventing localized overstress that could lead to damage. At the same time, the axle must work with the steering system to enable flexible directional control and cooperate with the braking system to accurately transmit braking force to the wheels, ensuring driving safety.

It is worth noting that performance requirements for truck axles vary significantly across different operating scenarios: axles for long‑haul logistics trucks emphasize lightweight design and smooth operation to reduce fuel consumption and driver fatigue; whereas axles for engineering and mining applications require enhanced structural strength and wear resistance to withstand harsh and complex road conditions. In short, axle performance directly determines a vehicle’s handling stability, driving safety, and operational efficiency, making it a vital element of a commercial vehicle’s core competitiveness.

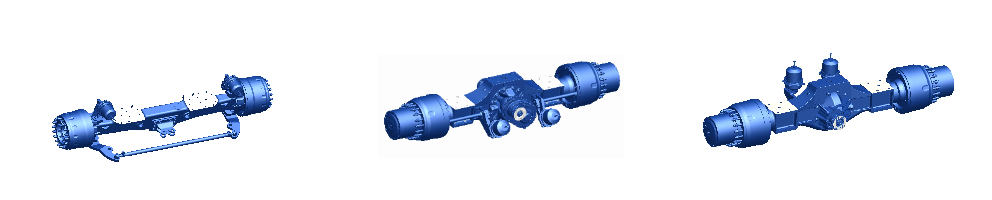

Based on functional differences, truck axles can be categorized into drive axles, steering axles, support axles, and others. Among these, the drive axle is the most widely used in heavy‑duty applications due to its power‑transmission capability. As the key device that transmits engine power to the wheels after speed reduction and torque increase, the drive axle integrates core components such as the main reducer, differential, and axle shafts. Its technical level directly determines the vehicle’s traction performance and load‑bearing limits—the transmission efficiency of the main reducer affects power loss, the design of the differential ensures proper wheel speed differentiation during turns, and the strength of the axle shafts determines the stability of power delivery. Especially for engineering machinery, agricultural machinery, and mining machinery that often operate under high‑load, high‑intensity, and complex terrain conditions, the reliability of the drive axle is a fundamental prerequisite for long‑term stable equipment operation.

Taking mining as an example: mining trucks typically travel on rugged, unpaved roads in mining areas, where sharp rocks, deep pits, and other obstacles are common, all while carrying hundreds of tons of ore over extended periods. This demands that the corresponding mining truck drive axle possess three core strengths: first, superior impact resistance to withstand instant shocks from road protrusions and rock collisions; second, excellent wear resistance to combat erosion from dust and gravel on internal components; third, ultra‑high load‑bearing capacity to meet the demands of heavy‑haul transportation. If the mining truck drive axle fails to meet performance standards, issues such as axle‑shaft fractures or differential failures can easily occur, leading to operational downtime and significant economic losses for mining companies.

When it comes to highly reliable drive axles designed for specialized machinery, the professional drive axle manufacturer—Shandong Lutong—has become a trusted partner for many enterprises both in China and abroad. Since its establishment, Shandong Lutong has focused on the research, development, production, and sales of drive axles. Leveraging deep insight into various operating scenarios, the company has built a comprehensive drive axle product system that is fully compatible with multiple fields including engineering machinery (e.g., excavators, loaders, cranes), agricultural machinery (e.g., tractors, combine harvesters, seeders), and mining machinery (e.g., mining trucks, mining loaders). Among these, its independently developed mining truck drive axle has earned widespread acclaim in domestic and international mining markets thanks to its outstanding performance.

Shandong Lutong’s core competitiveness stems from its well‑structured R&D system and stringent whole‑process quality control standards. To ensure technological leadership, the company has assembled a professional R&D team led by industry‑experienced experts, with R&D personnel accounting for over 15% of the workforce—including core technical talents with more than 20 years of drive axle R&D experience. The company invests 12% of its annual revenue in R&D, operates a Drive Axle Engineering Technology Research Center, and is equipped with advanced simulation laboratories, fatigue‑testing laboratories, and other R&D platforms, having overcome numerous core technical challenges.

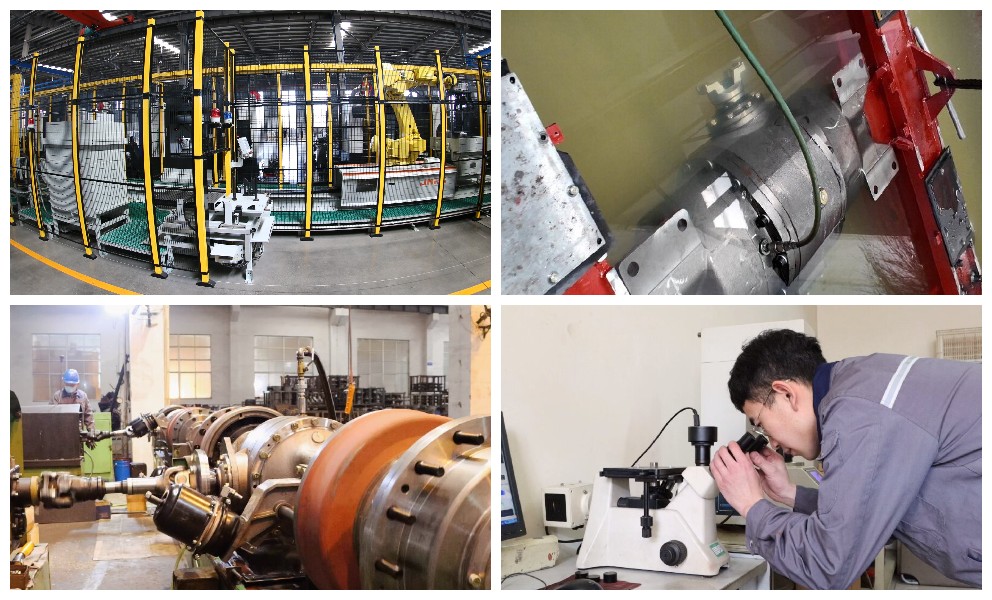

In the manufacturing process, the company employs imported CNC machine tools, automated welding production lines, and intelligent processing lines, achieving fully automated operation from component machining to final assembly. CNC machining accuracy reaches 0.001 mm, ensuring the compatibility of core parts; the automated welding line uses robotic welding technology, improving weld‑strength uniformity by 30% and eliminating quality fluctuations associated with manual welding; the intelligent processing line is equipped with an online inspection system that monitors assembly accuracy in real time. The application of this advanced equipment not only increases drive axle production capacity but also effectively ensures consistency in product precision.

Simultaneously, the company has established a whole‑process quality control system covering raw material procurement, production processing, and finished‑product inspection. All raw materials are sourced from well‑known domestic and international suppliers and must undergo eight inspection steps—including material analysis and mechanical property testing—before being accepted. Finished products are subject to 16 rigorous inspection procedures such as static‑load testing, fatigue testing, sealing testing, and high‑/low‑temperature environmental testing. Mining truck drive axles additionally undergo a 1,000‑hour heavy‑load simulation test to verify reliability under extreme conditions, resulting in a product qualification rate as high as 99.8%.Thanks to their excellent quality, the company’s products are ISO 9001 certified and boast a service life that is 20% longer than the industry average, effectively reducing customers’ maintenance costs and downtime losses.

With the acceleration of global economic integration, Shandong Lutong is actively expanding into international markets. Relying on high‑quality products and a comprehensive foreign‑trade service system, it is steadily increasing its global market share. Currently, the company’s drive axles are exported to regions and countries including Russia, Belarus, and Iran. Shandong Lutong’s foreign‑trade team has conducted on‑site inspections at mining sites to optimize the load‑bearing structure and sealing design of its drive axles. To better serve global customers, the company has formed a professional foreign‑trade service team whose members possess extensive international trade experience and are fluent in multiple languages, enabling them to respond promptly to product inquiries and technical questions.

To meet the market demands of different countries and regions, the company also offers customized product solutions. Each project is assigned a dedicated manager who follows the process from design and R&D through production and delivery, ensuring effective implementation. In logistics, Shandong Lutong has established long‑term partnerships with reputable logistics companies. For heavy products such as mining truck drive axles, it provides customized packaging solutions using solid‑wood pallets and shock‑absorbing materials to reduce the risk of damage during transportation, ensuring safe and efficient delivery. The average lead time for foreign‑trade orders is short, with an on‑time delivery rate of 98%.

Furthermore, the company has built a global after‑sales service network staffed with professional technicians and backed by sufficient spare‑parts inventory. This enables a rapid response to after‑sales needs, providing customers with comprehensive services including on‑site repairs, technical guidance, and parts replacement—fully addressing the after‑sales concerns of overseas clients.

At present, the global engineering, agricultural, and mining machinery industries are moving toward larger scale, greater intelligence, and higher efficiency. Market demand for high‑performance mechanical components is growing, and as a core component, the quality and reliability of truck axles have become key indicators of a machinery product’s competitiveness. In this context, Shandong Lutong consistently adheres to the business philosophy of “Quality as the Foundation, Innovation as the Driver, and Customer First,” continually improving its drive axle R&D and manufacturing capabilities, optimizing product structure, and refining its service system.

The company keeps pace with industry trends by actively developing intelligent drive axle technology—it has already launched an articulated truck drive axle project. At the same time, it continues to expand product application scenarios. In response to the development needs of new‑energy mining trucks, Shandong Lutong is developing drive axles compatible with new‑energy power systems, optimizing transmission efficiency and reducing energy consumption to support the industry’s green transformation. Whether the requirement is for heavy‑duty drive axles suited to construction scenarios, high‑efficiency axles for agricultural production, or highly durable mining truck drive axles for mining operations, Shandong Lutong can accurately meet customers’ individualized needs and provide more efficient, more reliable drive axle solutions worldwide.

With solid technical expertise, outstanding product quality, and comprehensive foreign‑trade services, Shandong Lutong is steadily growing into a leading enterprise in the global drive axle sector, helping domestic and international customers enhance operational efficiency and maximize economic benefits.

If you would like to learn more about drive axles, truck axles, mining truck drive axles, or if you have cooperation intentions, please contact Shandong Lutong through the message board or by private message. We will respond to your needs promptly and provide you with detailed product information and professional technical consultation. We look forward to advancing together with global customers and establishing mutually beneficial, long‑term cooperative relationships!