Shandong Lutong Adds Manual Precision Cleaning Line to Enhance Drive Axle Quality

Recently, Shandong Lutong Machinery Co., Ltd. has officially completed the commissioning and launch of a new manual precision cleaning line. This cleaning line is specifically designed for the core components of drive axles, fully covering the cleaning process for castings used in engineering machinery drive axles, agricultural machinery drive axles, and mining machinery drive axles. This production line upgrade not only further improves Shandong Lutong’s end-to-end production and processing system for drive axle products but also, through precise full-process cleaning of castings from arrival to pre-painting, strengthens product quality control at the source. It provides global customers with more stable and reliable core component solutions for drive axles, demonstrating the company’s commitment to deep‑rooted quality and continuous refinement in drive axle manufacturing.

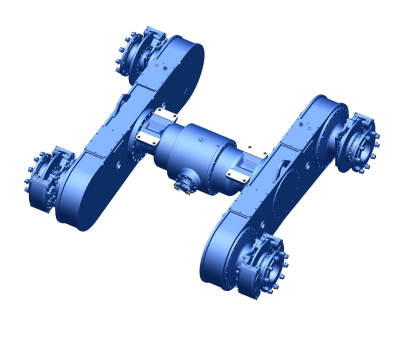

In the engineering machinery, agricultural machinery, and mining machinery industries, the drive axle serves as the equipment’s “power core transmission component.” Its quality and stability directly determine the entire machine’s operational efficiency, safety performance, and service life. Products such as loader drive axles, which operate under complex working conditions, face long‑term challenges including high‑intensity loads, bumpy impacts, and dusty, humid environments. This places extremely high demands on the surface precision, sealing, and corrosion resistance of core components. As a specialized enterprise with over thirty years of experience in drive axle R&D and manufacturing, Shandong Lutong has always regarded “quality as the foundation of the enterprise” as its core development strategy. Through strict control over product details, the company has built a strong reputation in the global market. Its products, including engineering machinery drive axles and loader drive axles, are exported to multiple countries and regions such as Russia, Belarus, and Iran, making Shandong Lutong a preferred matching supplier for many overseas OEM manufacturers.

The newly added manual precision cleaning line represents an important step by Shandong Lutong in response to market demand upgrades and deepened quality control. Compared with fully automated cleaning lines, the manual grinding mode, while requiring higher professional skills from operators, offers irreplaceable advantages in cleaning precision, coverage of hard‑to‑reach areas, and personalized adaptation. To ensure cleaning effectiveness, Shandong Lutong has not only designed a standardized process for the cleaning line, clarifying operational specifications and quality standards for each step, but has also conducted systematic pre‑job training for operators. The training covers multiple aspects, including the structural characteristics of drive axle core components, key points of cleaning techniques, and quality inspection standards. This ensures that every operator can accurately control grinding force and precision.

According to the head of Shandong Lutong’s Production Technology Department, the cleaning process for core drive axle castings runs through critical stages of production. This new cleaning line achieves full‑cycle coverage of this process. Specifically, after core drive axle castings such as axle housings, axle arms, main reducer housings, and differential housings leave the foundry and arrive at the machining workshop, they first enter the rough cleaning stage of the cleaning line. The main objective of this stage is to remove surface rust, handling marks from transportation, and residual foundry sand from the castings, clearing obstacles for subsequent precision machining. Operators, using their professional judgment, will select appropriate grinding tools based on the structural characteristics of different castings. This ensures thorough removal of surface impurities while avoiding damage to the casting itself, fully preserving the structural integrity of the castings.

After rough cleaning and preliminary quality inspection, the castings enter the core stage of the cleaning line—the precision grinding phase. This stage is crucial for ensuring the precision of drive axle products, focusing on the precise removal of residual surface burrs, flash, and impurities around machined holes left after preliminary mechanical processing. It is important to note that components such as axle housings and main reducer housings often feature complex cavity structures and connection holes. If burrs and impurities in these areas are not completely removed, they can directly affect subsequent assembly precision, leading to abnormal component fit clearances. This, in turn, can cause issues such as abnormal noise and increased wear, seriously affecting the operational stability of the drive axle.

Operators at Shandong Lutong will use specialized precision grinding tools to meticulously clean various cavities and holes of the castings point by point. Through a dual verification method of “visual inspection and tactile feel,” they ensure that the surface flatness error of castings is controlled within industry‑leading standards. Taking the axle housing of a loader drive axle as an example, the shaft‑hole connection areas inside have extremely high requirements for surface precision. Operators must perform repeated grinding and inspection to ensure that no burrs remain around the holes, guaranteeing precise mating between the subsequent transmission shaft and the axle housing. This enhances the power transmission efficiency and operational smoothness of the loader drive axle.

In addition to rough cleaning and precision grinding, the cleaning line also handles surface pretreatment before painting. This stage directly affects the appearance and corrosion resistance of drive axle products. Since castings may retain some original paint and oxidation layers from the casting process, painting directly over them would result in poor adhesion of the new paint, leading to issues like peeling and flaking, significantly shortening the product’s service life. To address this, operators on the cleaning line use specialized grinding techniques to thoroughly remove the original paint, oxidation layers, oil stains, dust, and other impurities from the casting surface, creating a uniformly rough surface. This treatment not only greatly improves the adhesion of the new paint but also enhances the wear resistance and corrosion resistance of the paint film. It ensures that the drive axle maintains good appearance and protective performance even after long‑term use in harsh outdoor, dusty, and humid environments.

To further strengthen quality control, Shandong Lutong has established multiple quality inspection checkpoints at various stages of the cleaning line. After each cleaning step, quality inspectors conduct comprehensive inspections of the castings against strict quality standards, including indicators such as surface cleanliness, flatness, and hole precision. Only castings that meet all standards proceed to the next production stage. This dual quality assurance system of “process control and final inspection” ensures that every drive axle product leaving the factory meets quality requirements. It also gives Shandong Lutong’s products, such as engineering machinery drive axles and loader drive axles, a distinct quality advantage in the market.

The commissioning of this manual precision cleaning line marks an important milestone in Shandong Lutong’s efforts to advance production process iteration and upgrading. It is also a practical demonstration of the company’s philosophy of “quality first, customer foremost.” For a long time, Shandong Lutong has remained focused on technological R&D and process innovation in the field of drive axles. Through deep insight into industry needs, the company continuously optimizes production processes and improves product quality. Its product portfolio covers various categories, including engineering machinery drive axles, loader drive axles, agricultural machinery drive axles, and mining machinery drive axles, meeting the personalized needs of different industries and working conditions. Relying on a complete manufacturing system and stringent quality control processes, Shandong Lutong’s drive axle products have not only gained wide recognition in the domestic market but have also successfully entered overseas markets, establishing long‑term stable cooperative relationships with OEM manufacturers in multiple countries.

Looking ahead, Shandong Lutong will continue to be market‑demand‑oriented, with quality improvement at its core, constantly advancing the iteration, upgrading, and technological innovation of production processes. The company plans to further optimize operational processes on the existing cleaning line, introduce more advanced grinding tools and inspection equipment, and continuously improve cleaning efficiency and precision. Simultaneously, it will increase investment in the R&D of core drive axle technologies, continually enhancing product performance and intelligent features to provide global customers with more valuable drive axle solutions.

A representative of Shandong Lutong stated that the company will always adhere to its original aspiration of "building the enterprise on quality and driving development through innovation." By implementing stricter standards to control the entire production process, the company aims to repay the trust and support of global customers with superior products and services. In the future, Shandong Lutong will continue to deepen its expertise in the field of drive axles, striving to become a globally leading supplier of core drive axle components and contributing to the high-quality development of the engineering machinery, agricultural machinery, and mining machinery industries.