Lutong Heavy Industry put into operation a new drive axle welding automatic line

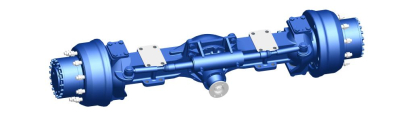

Shandong Lutong Heavy Industry Machinery Co., Ltd. recently announced that its new welding automatic line designed for the welding of loaders and tractor drive axle shaft pipes has been officially put into operation. This important measure marks the major transformation of enterprises from traditional production methods to intelligent and precise manufacturing in the field of drive axle manufacturing, laying a solid foundation for the quality improvement and process innovation of drive axle products.

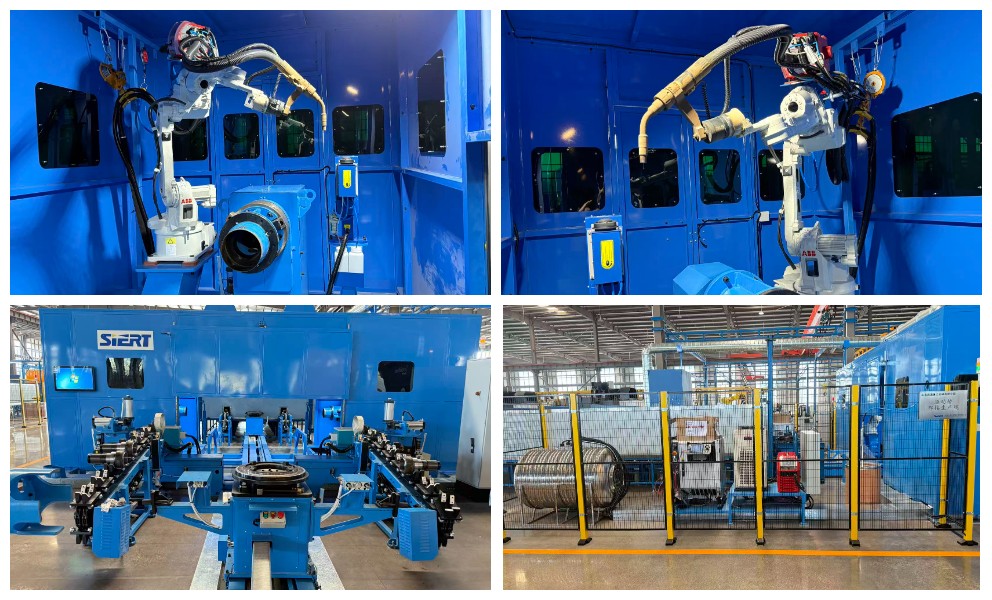

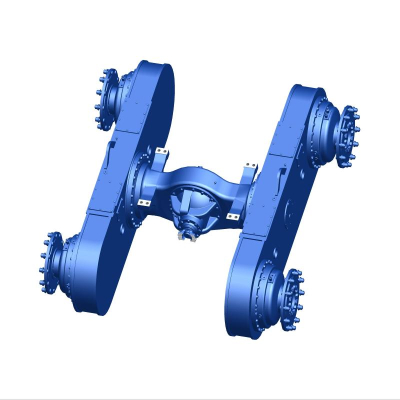

As the core component of construction machinery, the quality of the drive axle is directly related to the service life and reliability of the entire machine. For a long time, the accuracy control of the drive axle welding process has been a technical difficulty in the industry. The welding automatic wire put into production by Lutong Heavy Industry this time has achieved a qualitative leap in the drive axle welding process through full-process automated control and data closed-loop management. The production line integrates ABB robots, intelligent logistics systems and visual identification units, which can complete the entire process of automated operations from workpiece loading, precise positioning, welding molding, and quality inspection. This innovation not only greatly improves the production efficiency of the drive axle, but also ensures the consistency and reliability of the product through precise process control.

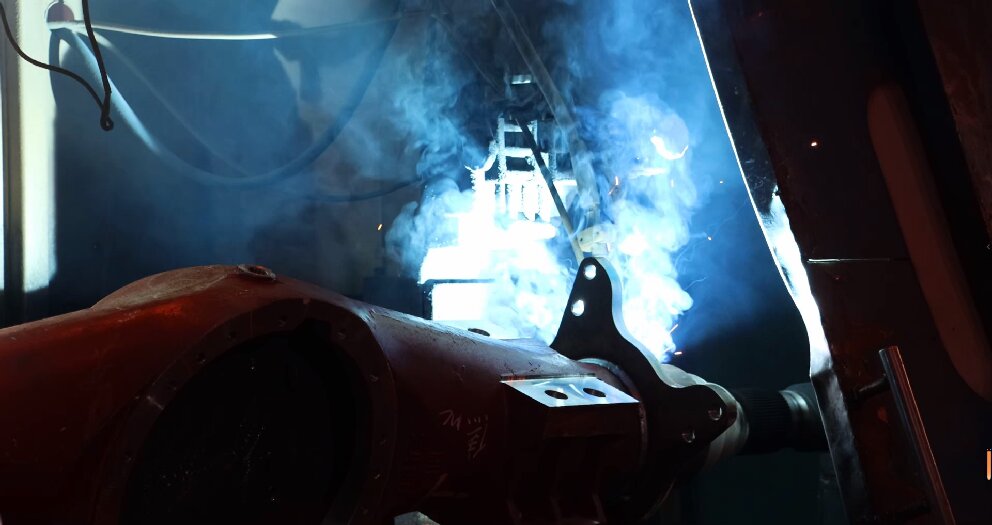

In the manufacturing process of drive axle, the coaxiality of the axle shell and the wheel edge mounting plate is a key factor affecting product performance. The new welding automatic wire controls the coaxial error within an extremely low range through step-by-step press-fitting and hydraulic closed-loop control system, which significantly improves the transmission efficiency and load-bearing capacity of the drive axle. The improvement of welding quality directly leads to the optimization of product performance. The drive axle showed excellent fatigue life and structural stability in the bench test, effectively solving the additional stress problems caused by insufficient accuracy in traditional welding processes.

Quality stability: the core guarantee of drive axle reliability

The quality stability of the drive axle is directly related to the overall performance of the construction machinery. Lutong Heavy Industry's new welding automatic wire has achieved "nearly zero defect" manufacturing of drive axle welding quality through triple protection mechanism. First, the closed workstation and efficient dust removal system ensure the environmental purity of the drive axle welding process; second, the protective gas flow control system ensures the stability of the welding process; finally, the robot's high repeat positioning accuracy provides technical guarantees for the consistency of the drive axle weld. The comprehensive application of these measures has significantly reduced the porosity of the drive axle welding and the weld quality has reached the industry's advanced level.

The long-term service life of the drive axle is the focus of users. The new welding automatic wire significantly extends the service life of the drive axle by improving the accuracy and consistency of the welding process. Under extreme working conditions such as mines and ports, the overhaul cycle of the drive axle is effectively extended, reducing maintenance costs and downtime for users. This improvement not only reflects Lutong Heavy Industry's strict requirements on product quality, but also demonstrates the company's technical strength in the field of drive axle manufacturing.

Efficiency improvement and industry impact: a new benchmark for drive axle manufacturing

The production of the newly welded automatic line of Lutong Heavy Industry has set a new performance benchmark for the drive axle manufacturing industry. The significant shortening of production beats and the significant improvement of equipment utilization fully reflect the positive impact of intelligent manufacturing on the production efficiency of drive axles. At the same time, the reduction in quality costs and the decline in rework rate further prove the economic and practicality of the new production line. The improvement of drive axle manufacturing efficiency not only brings direct economic benefits to the company, but also provides a reference for the technological progress of the entire industry.

The reliability of drive axles is one of the most important concerns for engineering machinery users. Through precise process control and intelligent quality management, the new production line significantly improves the service life and overhaul cycle of the drive axle. This improvement not only reduces the maintenance costs of users, but also enhances the market competitiveness of Lutong Heavy Industry Drive Axle products. In the fierce industry competition, the reliability and durability of drive axles have become a key factor in winning customers' trust.

The technological upgrade of drive axle manufacturing has a profound impact on the development of the industry. Through the production of the newly welded automatic wire, Lutong Heavy Industry not only improved its product quality and technical level, but also pointed out the direction for the development of the entire drive axle manufacturing industry. Intelligence, precision and flexibility have become an inevitable trend in driving axle manufacturing, and Lutong Heavy Industry is the active leader and practitioner of this trend. In the future, with the stable operation of new production lines, enterprises are expected to further consolidate their competitive advantages in the drive axle market and provide better products and services to global customers.

As the core component of construction machinery, the manufacturing level of the drive axle is directly related to the performance and reliability of the entire machine. The start of the welding automatic line of Lutong Heavy Industry this time is an important achievement of the company's long-term deepening in the field of drive axle manufacturing. Through intelligent upgrades, quality stability improvement and flexible production capacity enhancement, the company not only provides solid guarantees for the reliability of drive axle products, but also contributes important strength to the transformation and upgrading of China's manufacturing to intelligence and high-end.