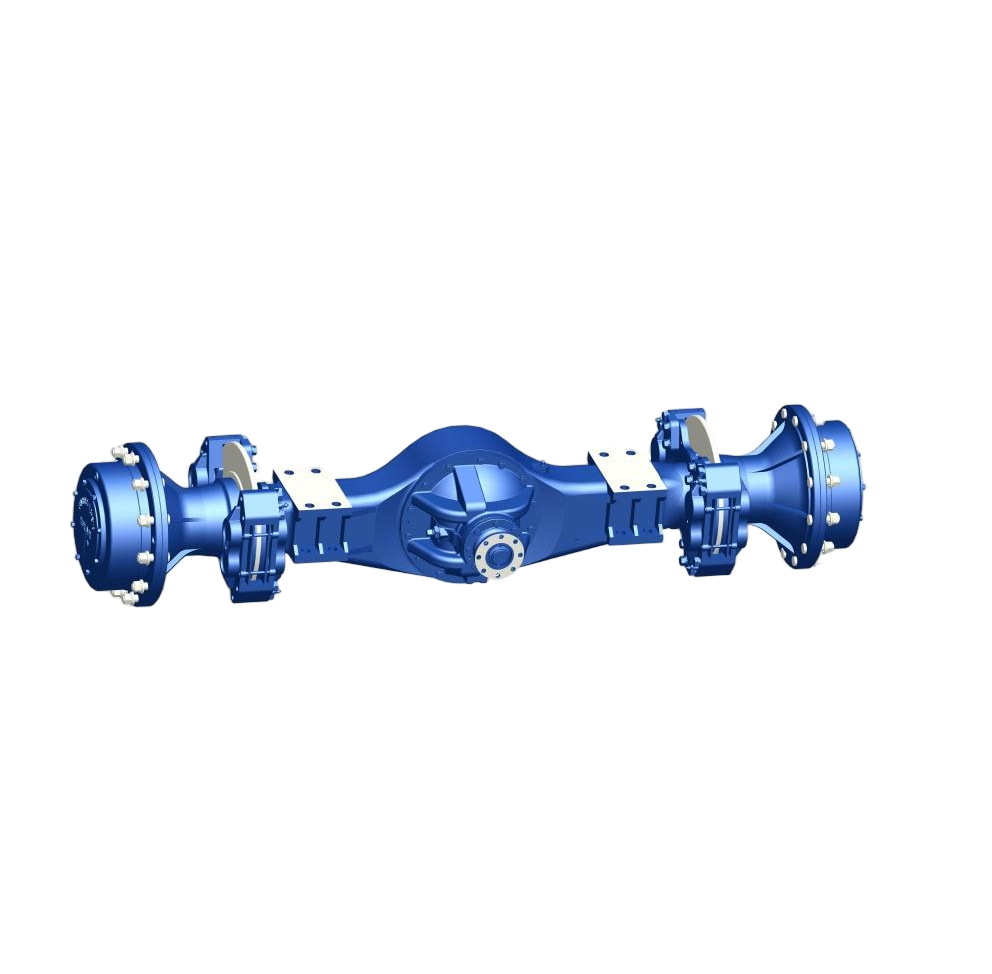

Electric Loader Axle

1. Original manufacturer of drive axles for Sany Group, Shantui Construction Machinery Co., Ltd., Lovol Heavy Industry, and Divanlen Aidiqi modern electric loaders.

2. Supports customized drive axle solutions for loaders.

3. Factory direct shipping with a 30-day delivery cycle.

Product Structure:

The electric loader axle electric loader is customized, integrating transmission efficiency, braking safety, structural durability and adaptability. It can fully adapt to the operating scenarios of the electric loader to help improve the loading and operating performance of the equipment.

Customized adaptation: exclusive research and development, precise matching of working conditions and power, and fits the operating characteristics of the equipment

Flexible transmission: two-stage reduction structure, optional conventional differential / NO-Spin LSD, to deal with multi-scene power transmission

High-efficiency gear: NGW planetary gear design, compact structure, wide speed ratio, strong load-bearing capacity

Reliable brake: disc-type caliper brake, large braking torque, stable performance, and can quickly stop and avoid hazards in various working conditions

Strengthen damage resistance: traditional drive axles upgrade to resist strong motor impact, reduce wear and extend life

Compatibility with all scenarios: Excellent compatibility performance, maximize the release of loader operation potential, and support improvement of loading performance

Main technical parameters:

Total transmission Ratio | 22.853 |

Maximum input torque | 5800N.m |

Load each axle | 30000Kg |

Braking oil pressure | 11Mpa |

Braking capacity | 8.8ml |

Braking moment | 13050N.m |

Oil request for driving axle (API standard) | GL-5:85W/90 Gear Oil (above -12 ℃) |

Oil request for brake | L-HL46 Hydraulic oil |

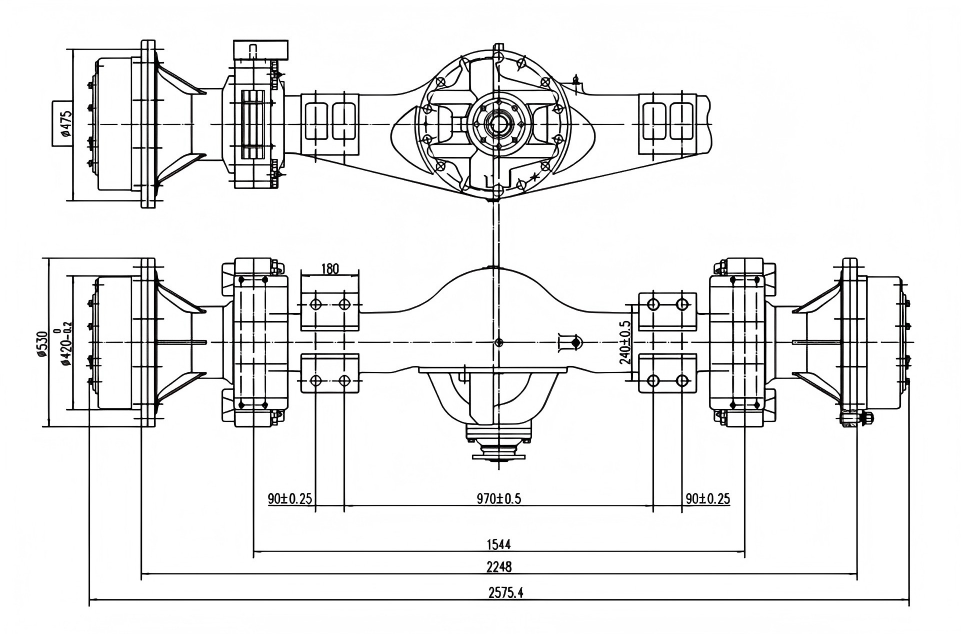

Dimension Sketch:

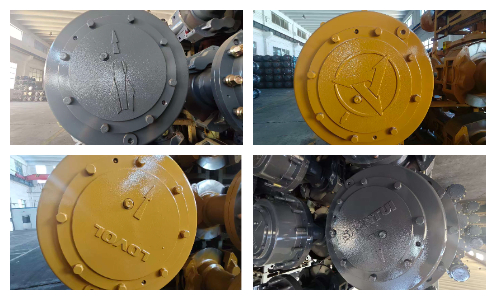

Electric Loader Axle Component Machining:

The core components of our company's electric loader drive axles are now processed through automated and intelligent manufacturing. Key parts including the axle housing, main reduction gear housing, planetary carrier, and differential housing are all produced on intelligent processing lines. These automated lines exclusively utilize internationally leading robots from brands such as ABB and KUKA. This approach effectively ensures product quality while reducing costs.

Electric Loader Axle Assembly:

The electric loader drive axle assembly production line enables unified assembly of all components for drive axles. The automated assembly process minimizes assembly errors, effectively ensuring assembly precision, extending the service life of electric loader drive axles, and reducing faults such as abnormal noises and oil leaks. It possesses a high-performance production capacity of 50,000 drive axles of various types annually.

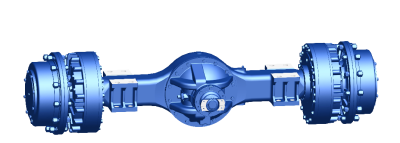

Electric Loader Axle Finished Product Display:

Our company's electric loader drive axles hold a 30% market share in China. We have established long-term, stable partnerships with internationally renowned brands such as Sany Group, Lovol Heavy Industry, and Shantui Group. Lutong Axle is now expanding globally to build a world-renowned brand.

BRETON SANY LOVOL SHANTUI |

Quality Assurance

We adhere to strict quality control standards throughout the production cycle of Electric Loader Axle. From the selection of raw materials to the application of precision machining processes , each link undergoes multi-stage inspection. The axle assembly also goes through dynamic load testing, braking performance testing, and durability testing under simulated working conditions to ensure it meets long-term operational stability in harsh environments like dust, vibration, and variable temperatures.

Corporate Honors

Our Electric Loader Axle production system has passed the authoritative certifications such as ISO 9001, ISO 14001, etc., and has also been awarded national high-tech enterprises, "specialized, specialized, and new little giants" and provincial famous brand products, and holds 100 related patents.

If you have procurement intention or technical consultation needs for our Electric Loader Axle, whether it is customizing the adaptation plan or understanding the supply cycle, please contact us at any time through the official website message, phone number, etc. We will use professional services to efficiently connect to you to help your production and operation needs.