Welcome customers with quality and win-win with technology!The SANY delegation praised the hard power of Shandong Lutong drive axle

Recently, a delegation from SANY Heavy Industry (SANY), a global benchmark company in the field of construction machinery, made a special trip to visit Shandong Lutong Machinery Technology Co., Ltd. (hereinafter referred to as “Shandong Lutong”).This inspection is not only an accurate survey of core component suppliers by industry giants, but also an important opportunity for Shandong Lutong to demonstrate the hard power of drive axle R&D and manufacturing.As a leading enterprise in the field of domestic drive axles, Shandong Lutong has long become a strategic partner of many leading construction machinery companies with more than 30 years of deep cultivation and accumulation. This visit of SANY is even more powerful confirmation.

Since its inception, Shandong Lutong has focused on the core track of construction machinery, agricultural machinery, and mining machinery drive axles. Relying on the “specialized and refined” development strategy, Shandong Lutong has achieved a scale advantage with an annual production capacity of more than 50,000 sets.Its products cover more than 30 provinces and cities in China, and are exported to Russia, Belarus, Iran and other countries and regions.We have maintained long-term and stable cooperation with well-known companies in the Sany, XCMG, Liugong, Shantui and other industries that visited this time.The SANY delegation visited the three core areas of the R&D center, the intelligent production workshop, and the quality inspection and delivery area. Through on-site observation, technical inquiries, and data verification, they gained a comprehensive and in-depth understanding of the comprehensive strength of this professional manufacturer of drive axles.

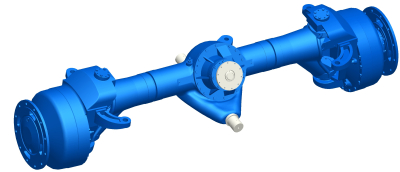

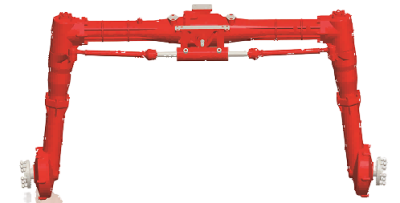

R&D strength is the core competitiveness of Shandong Lutong, which is also the key focus of the SANY delegation.The technical director of the company systematically presented the technical advantages of the main products such as excavator drive axles and loader drive axles to the delegation.Shandong Lutong has formed a professional R&D team of 20 people, including 3 senior engineers with more than 30 years of drive axle R&D experience, and its deep talent pool provides a solid support for technological innovation.According to the needs of different working conditions, the products customized by the team have their own highlights.Up to now, Shandong Lutong has won a number of drive axle-related patents.

From technical drawings to qualified products, intelligent production is the key link for Shandong Lutong to ensure quality.The company's upgraded drive axle dedicated production line has become the focus of the delegation's stop and observe.In the workshop, imported CNC machining centers accurately complete the processing of the core components of the drive axle, and the error is controlled within 0.005mm; fully automatic welding robots operate efficiently, with a welding and stitching failure rate of 100%, and the efficiency is 3 times that of traditional manual labor.It is also worth mentioning that the workshop is fully equipped with the MES production execution system, from the entry of raw materials into the warehouse to the parameter recording of each processing process, to achieve the whole process traceability.This intelligent and refined production management model ensures the stability of the product quality of the drive axle.

“Product qualification is not the end point, customer confidence is the goal”, this is the quality concept that Shandong Lutong adheres to.At the quality inspection center, the delegation witnessed the strict standards of its quality: the raw material assembly must undergo spectral composition testing and mechanical properties testing; the drive axle assembly must complete static load testing, fatigue testing, and sealing performance testing.According to the manager of the quality inspection department, the pass rate of the company's drive axle products has been stable all year round. The drive axle was sent to Russia last year to achieve zero failure in continuous operation.

At the symposium, the SANY delegation highly praised Shandong Lutong's strength, and Shandong Lutong further elaborated the company's development philosophy and service commitment.He said that the company has always taken “providing more reliable drive axle products for the construction machinery industry" as its mission, not only focusing on technology research and development and quality control, but also emphasizing customized service capabilities.According to the characteristics of different customers' models and working conditions, they can quickly respond to the development of exclusive solutions, which is also the key to the company's ability to win the trust of many leading companies.At present, Shandong Lutong has established a perfect pre-sales technical docking, in-sales production follow-up, and after-sales rapid response system, and a 24-hour dedicated service team to ensure that customer problems are resolved in a timely manner.

The visit of the SANY delegation is not only a cooperation negotiation, but also a concentrated demonstration of the strength of Shandong Lutong's drive axle R&D, production and service chain.After more than ten years of deep cultivation, Shandong Lutong has set a professional benchmark in the field of drive axles with technological innovation as the core, quality control as the cornerstone, and customer demand as the guide.In the future, the company plans to continue to invest 8% of its annual revenue in research and development, focusing on the lightweight and intelligent upgrading of the drive axle, and continuously improving its core competitiveness.As an important supplier of core components of China's construction machinery, Shandong Lutong will continue to rely on its own strength to enable the development of the industry, and at the same time work with more industry giants like SANY to jointly promote Chinese construction machinery brands to the world.