High-Performance Drive Axle for Skidders Passes Authoritative Validation

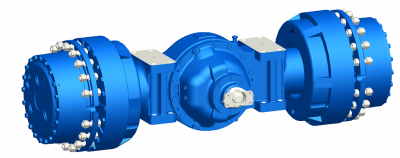

As global forestry mechanization accelerates today, high-performance, highly reliable specialized equipment has become the core key to enhancing forestry production efficiency and safety. For skidders (or loggers), a crucial transport link in forestry operations that operate year-round in primitive forests and mountainous regions with complex terrain and harsh environments, the performance requirements for their core transmission component – the drive axle – far exceed those for ordinary engineering machinery. Confronting this industry pain point, our company, leveraging decades of experience in heavy-duty drive axle R&D and manufacturing, has successfully launched the LTP75 series drive axle, specifically tailored for modern skidders. This product has not only passed extreme condition validation at a national-level authoritative laboratory but has also demonstrated exceptional adaptability in real-world forest operations. It is redefining the performance benchmark for forestry machinery drive systems with its disruptive innovations like the equalizer bar design, high-offset structure, and four-stage high-ratio transmission.

I. Born for Extremes: Confronting the Core Challenges of Forestry Operations

When traditional drive axles are applied to forestry machinery, they often face several formidable obstacles: 1) Uneven forest floors with tangled roots, mud, and slippery conditions pose severe challenges to ground clearance and mobility; 2) Heavy timber hauling requires sustained, immense traction torque, presenting the ultimate test for the strength and durability of the transmission system; 3) Operations on steep slopes and side slopes demand excellent anti-slip and vehicle stability control capabilities to ensure operational safety; 4) Long-term exposure to damp, dusty environments with drastic temperature swings requires exceptional sealing reliability and environmental adaptability from the drive axle.

To overcome these challenges, our R&D team conducted in-depth field research at several large domestic and international forest farms, engaging in profound exchanges with veteran equipment operators and maintenance engineers. Based on first-hand operational data and user pain points, the core design philosophy for the LTP75 series Logger Drive Axle was established: "Ultra-high Mobility, Extreme Traction, Absolute Reliability." From the conceptual design stage, the product abandoned compromised universal platform solutions, undergoing forward development entirely centered on the special mission of forestry machinery. Its signature equalizer bar structure flexibly connects the axle housing to the box via a precision slewing bearing, allowing the wheels greater freedom to adapt to rugged ground and maintain balanced tire contact pressure. This significantly improves mobility and travel stability on extreme terrain like stumps and ditches, constituting its core advantage over traditional rigid axles.

II. Technical Deconstruction: Four Core Innovations Forge Exceptional Performance

1. High-Offset Design & Equalizer Bar Structure: Redefining Mobility Boundaries

The most striking feature of the LTP75 drive axle is its revolutionary high-offset design. The centerline of the power input shaft is significantly raised, creating a substantial distance from the tire center. This design delivers two decisive advantages: First, the vehicle's minimum ground clearance achieves a qualitative leap, allowing key components like the main drive axle body and differential to easily avoid the most common ground protrusions in forest areas, fundamentally eliminating the "belly dragging" risk. Second, it optimizes the vehicle's center of gravity distribution. Combined with the oscillating function of the equalizer bar, vehicle stability and safety during side-slope operations are greatly enhanced. The internal transmission of the equalizer bar is not a simple chain drive but employs a more precise and efficient gear transmission system, achieving higher transmission efficiency and longer service life while ensuring flexible power connection.

2. Four-Stage High-Ratio Reduction Mechanism: Unleashing Massive Traction Force

Faced with the ultimate load of skidders hauling massive logs, conventional two or three-stage reduction mechanisms often fall short. The LTP75 drive axle innovatively integrates a four-stage high-ratio reduction system. This system cleverly distributes torque amplification between the main reducer and the wheel-side reducer, achieving an industry-leading total reduction ratio. The most tangible benefit is the ability to deliver more massive torque at the wheel under the same engine input power, providing the equipment with Herculean traction. Whether climbing steep slopes or self-recovering from deep mud, the robust torque reserve gives the equipment ample capability. Simultaneously, precisely calculated and optimized gear meshing parameters ensure excellent transmission efficiency is maintained even with the huge reduction ratio, avoiding unnecessary power loss.

3. Fully Enclosed Wet Brake System: Setting a New Standard for Safety and Durability

Forestry areas feature long downhill sections with heavy loads, where brake system reliability is directly related to life and property safety. This drive axle abandons traditional dry brakes, featuring a fully enclosed multi-disc wet brake system as standard across the series. The brake friction discs are fully immersed in cooling oil, achieving three major leaps: First, immense and linearly stable braking torque output, capable of handling long-distance, heavy-load downhill conditions. Second, excellent resistance to thermal fade, ensuring stable performance under continuous braking for very high safety. Third, the fully enclosed structure prevents ingress of wood chips, mud, sand, and moisture. Brake life can be several times that of dry brakes, essentially matching the drive axle's lifespan, greatly reducing maintenance frequency and costs. This system provides forestry machinery with braking assurance comparable to mining equipment.

4. Hydraulically Controlled Differential Lock: Ultimate Anti-Slip, Mastering All Terrains

For low-traction surfaces like muddy, snowy, or leaf-covered forest floors, the LTP75 drive axle is equipped with a responsive hydraulic differential lock. When the system detects single-wheel spin, the operator can instantly lock the differential via a switch, transferring 100% of the torque to the wheel with traction, immediately restoring powerful traction. Compared to automatic limited-slip differentials, hydraulic forced locking is more direct and reliable, offering stronger extrication capability, especially in extreme predicaments. This system ensures maximum mobility regardless of the complex, slippery surface encountered, minimizing downtime caused by wheel spin.

III. Precision Manufacturing: Millimeter-Level Craftsmanship under an ISO System

Exceptional design requires ultimate craftsmanship to realize. The birthplace of the LTP75 drive axle is a modern intelligent factory operating under the strict ISO 9001 Quality Management System. Every step, from raw material intake to finished product dispatch, is systematically and documentarily controlled, ensuring absolute product consistency and traceability.

In key component machining, core parts like the drive axle housing, differential carrier, and main reducer housing are precision-machined using dedicated fixtures and jigs. These custom fixtures ensure benchmark consistency and superior positioning accuracy for every part in batch production. Post-machining, instead of relying on sampling, 100% full inspection of all critical dimensions and geometric tolerances is performed. High-precision Coordinate Measuring Machines (CMMs) act like "industrial microscopes," not overlooking any micron-level deviations, generating a traceable data report for each part to ensure strict conformity with the rigorous design drawing requirements.

During assembly and final testing, an experienced assembly team transforms precision parts into high-performance assemblies following standardized procedures. However, assembly completion is not the end point. Every LTP75 drive axle must undergo an "ultimate test" on a dedicated comprehensive test bench before leaving the factory. No-load run-in tests check for smooth operation and noise levels. Load tests simulate actual working conditions to verify torque capacity and transmission efficiency. Sealing tests ensure no leakage under high-pressure spray. Only after passing all test items can the drive axle receive "dispatch approval" for delivery to the customer. This obsession with quality is the very foundation of product reliability.

IV. Authoritative Validation: National Laboratory Data Witnesses Extreme Durability

To provide the most objective and authoritative performance endorsement for the market, in July 2025, the LTP75 drive axle was sent to a top-tier Chinese national-level authoritative laboratory for an enhanced bench test designed to challenge its performance limits. The goal of this test was not to simulate ordinary conditions but to deliberately create an extremely harsh environment far exceeding real-world operational intensity.

The test employed an accelerated fatigue method, continuously applying high-intensity cyclic torque loads to the drive axle assembly. This is equivalent to concentrating the most severe stress conditions the equipment might encounter in its lifetime into a short period for intensive "bombardment," aiming to validate the product's ultimate durability and reliability margin. The final test report clearly indicated: the fatigue life and reliability indices of the LTP75 drive axle significantly surpassed common industry standards. Its robust design and excellent manufacturing process were proven fully capable of handling with ease the most severe, highest-intensity continuous challenges in forestry operations. This authoritative report from an independent national laboratory undoubtedly provides the most credible "technical passport" for the product's exceptional performance.

V. Triumph in Practice: First Vehicle Mounting Validation Earns Customer Acclaim

Laboratory data is cold, but market feedback is warm. Currently, this new drive axle specifically developed for skidders has successfully completed its first vehicle mounting validation with five units. These units were deployed in real forest operating environments for rigorous condition assessment lasting several months.

Throughout the validation period, the skidders equipped with the LTP75 drive axle operated smoothly and demonstrated reliable performance, with no quality failures related to the drive axle reported. It perfectly adapted to complex environmental changes from spring/autumn mud to winter snow. Its high-mobility design boosted operator confidence when navigating obstacle zones. Its powerful traction handled hauling large logs with ease, while the wet brake system provided reassuring braking assurance on long downhill sections. Initial feedback from the first users has been very positive, particularly praising the drive axle for being "powerful, stable, and requiring almost no maintenance worries." This fully verifies the drive axle's exceptional adaptability and durability under demanding application scenarios, marking its transition from an excellent design to a mature, reliable, and trustworthy end product.

VI. Future Outlook: Continuously Empowering Global Forestry Modernization

The successful R&D and validation of the LTP75 series Logger Drive Axle not only concentratedly reflects our company's technical strength in the special vehicle transmission field but also fulfills our deep commitment to global forestry customers. We deeply understand that every piece of equipment operating in the forest carries the heavy responsibility of improving efficiency, ensuring safety, and creating value.

Looking ahead, we will continue to be customer-demand-oriented and persistently iterate our products. More advanced versions integrating intelligent temperature control and wear monitoring sensors are already in the R&D pipeline, aiming for predictive maintenance to further reduce users' total operating costs. Simultaneously, we will continuously improve our service network and spare parts supply system covering key global forestry regions, ensuring our customers receive timely, professional technical support wherever they are.

We firmly believe that with the innovative design of the Equalizer Bar Drive Axle, the formidable power of the four-stage high-ratio system, the safety assurance of wet brakes, and the exceptional reliability validated by both national laboratory and real-world conditions, the LTP75 series drive axle is destined to become the preferred power solution for global forestry machinery manufacturers and end-users. Together with our partners, we will jointly promote world forestry production towards a new era of higher efficiency, greater safety, and increased intelligence.