Bulk Shipments Demonstrate Strength: Grader Drive Axle Series Goes Global

Recently, batches of meticulously manufactured grader drive axles have been systematically loaded in our shipping area, ready for dispatch to major OEMs and end-users both domestically and internationally. This product range, covering the full 160-220 horsepower spectrum, includes not only proven conventional models but also high-end models customized for extremely cold conditions, showcasing our profound technical expertise and strong manufacturing capability in the grader drive axle field. Previously, dozens of high-power 260-270 horsepower grader drive axles were sent to Belarus, where they are undergoing rigorous validation in large local mining operations.

At the shipping site, workers were methodically conducting final inspections. Every drive axle must pass stringent factory acceptance tests to ensure all performance parameters fully meet standards. The technical manager, indicating the products ready for shipment, explained: "This grader drive axle destined for Russia was developed specifically for local requirements. It incorporates a reinforced design and special low-temperature materials, enabling stable operation in extreme cold environments as low as -40°C. Feedback from initial field trials has been very positive, with clients highly praising the product's performance under harsh working conditions."

The conventional models – 160-200 HP and 200-220 HP grader drive axles – are primarily supplied to renowned domestic OEMs like Liugong, and are also scheduled for export to countries including Russia and Belarus, providing matched components for internationally known manufacturers like UMG and Amkodor. These products, validated over the long term in the market, have gained widespread recognition from global customers for their exceptional reliability and cost-effectiveness.

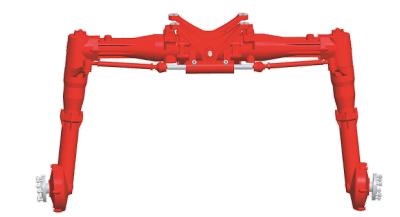

Technology Leadership: Equalizer Bar Design Enables Superior Performance

The core advantage of our grader drive axle series lies in its innovative equalizer bar design. This design connects the intermediate and rear wheels via a tandem drive structure, enabling the system to maintain consistent speed and torque distribution on both sides. This effectively solves the wheel slippage problem common with traditional drive axles in complex working conditions. Engineering test data show this design can reduce tire wear by over 30% while significantly improving the screed's leveling accuracy.

"The equalizer bar design is the key feature distinguishing our product from ordinary drive axles," emphasized the R&D director when describing the product characteristics. "It acts like a precise torque distributor, automatically adjusting the drive force to the wheels on each side based on road conditions, ensuring the equipment always achieves optimal traction performance." In practical application, this characteristic enables motor graders equipped with our drive axles to maintain stable operation across various complex terrains, delivering excellent performance in both road construction and mine site leveling.

It is worth noting that this series comes standard with limited-slip differentials across all models. This configuration further enhances the equipment's mobility in adverse conditions. When one wheel loses traction, the system automatically transfers torque to the wheel with grip, ensuring the equipment continuously receives sufficient traction. This feature is particularly crucial in complex road conditions like mud or soft ground, effectively preventing the equipment from getting stuck.

Regarding structural strength, the drive axle utilizes a heavy-duty engineering chain drive system, whose impact resistance and durability far exceed those of ordinary products. Practical validation confirms that this drive axle can withstand impact loads exceeding 150% of the rated capacity, fully meeting the most demanding construction requirements. Concurrently, the optimized lubrication system and sealing design ensure the product maintains a long service life even in harsh environments like dusty or damp conditions.

Customized Solutions: Triple-Drive Axle Conquers Specialized Conditions

Beyond the conventional equalizer bar series products, our company has developed a triple-drive customized drive axle for specific markets like Russia. This innovative design configures the front, intermediate, and rear axles all as drive axles, achieving true all-wheel drive. In practical tests, this configuration increased the equipment's traction force by over 40%,completely solving the problem of traditional motor graders easily slipping on soft ground or steep slopes.

The front axle employs a classic portal axle design, with a carefully calculated offset between the input shaft centerline and the wheel center. This design significantly increases the vehicle's ground clearance while ensuring steering performance. Engineering measurement data indicate that motor graders using the portal axle structure achieve a minimum ground clearance more than 25% higher than traditional designs, allowing the equipment to easily handle complex road conditions like potholes and rubble, effectively avoiding undercarriage impact risks.

The intermediate and rear axle assemblies use a unified platform design, differing only in the opposite rotation direction of the input gears. This design greatly improves component commonality, allowing customers to reduce spare parts inventory and lower maintenance costs. Furthermore, the flexible connection to the frame via an oscillating suspension enables the equipment to better adapt to uneven ground, ensuring more wheels maintain contact simultaneously, which enhances both traction and travel stability.

Global Validation: Quality Earns International Reputation

Our grader drive axle series products have been validated in multiple global markets. Domestically, through long-term cooperation with mainstream manufacturers like Liugong, the products have endured tests in various working conditions. Statistics show that the Mean Time Between Failures for motor graders equipped with our drive axles in road construction exceeds 3,000 hours, a figure that reaches international advanced levels.

In the international market, the products also perform excellently. The 260-270 HP drive axles sent to Belarus withstood extreme challenges in mining applications. Local user feedback confirms that these products can start and operate normally even in low-temperature environments of -40°C, their reliability completely surpassing that of international comparable products. Especially under continuous heavy-duty operating conditions, the main components of the drive axle demonstrated good durability, with service life far exceeding expectations.

"We are impressed by the product's adaptability," stated a Belarusian client. "The annual temperature variation in the Siberian region exceeds 80°C, from +35°C in summer to -45°C in winter, which is a severe test for any mechanical equipment. But your company's drive axle maintained stable performance across the entire temperature range, which is truly commendable."

In the Russian market, the triple-drive customized drive axle has received particularly widespread acclaim. Several clients reported that this product, specifically developed for local special conditions, genuinely solves pain points in their operations. Its exceptional mobility and reliability have helped users significantly improve construction efficiency and reduce operating costs. Based on the initial successful experience, multiple Russian clients have recently placed additional orders.

Manufacturing Strength: Intelligent Manufacturing Ensures Product Quality

Exceptional product performance relies on advanced manufacturing processes and strict quality control. In our intelligent production workshop, dozens of high-end CNC machines precisely process various components of the drive axle. Every step, from core part machining to final assembly, achieves automated and intelligent production.

The quality inspection phase is equally critical. The company has a well-equipped testing laboratory with advanced devices like coordinate measuring machines and spectrometers. Every product batch undergoes strict inspection through over 30 steps, including material analysis, dimensional checks, and performance tests. It is especially noteworthy that the company has also established a complete axle test bench capable of simulating various working conditions for comprehensive drive axle performance testing.

To ensure product reliability, all new models must pass rigorous durability tests before mass production. On the test track, drive axles undergo continuous full-load testing, including challenges like impact loads and cyclic stress under extreme conditions. Only products passing all these tests are ultimately delivered to customers.

Service Support: Global Presence Facilitates Client Success

To better serve global customers, our company has established a comprehensive after-sales service system. Domestically, multiple regional service centers provide 24/7 technical support. In international markets, through cooperation with local distributors, spare parts warehouses and technical service teams have been set up in key markets like Russia and Belarus.

"We commit to providing a solution within 4 hours of receiving a service request and completing spare parts shipment within 48 hours," stated the after-sales dervice director. "This rapid response mechanism ensures our clients' equipment availability." Statistics indicate the fulfillment rate for this service commitment exceeds 98%, earning widespread praise from customers.

Beyond timely after-sales service, the company also provides professional technical training. Regular technical training sessions are held for customers, covering product usage, maintenance key points, and troubleshooting experience sharing. Since the beginning of this year, over 200 equipment management and maintenance personnel from domestic and international clients have been trained, effectively enhancing their ability to resolve issues independently.

It is worth emphasizing that the company has also established a robust customer feedback mechanism. Through regular follow-up visits and on-site surveys, issues encountered and suggestions from customers during product use are collected. This first-hand information provides crucial input for continuous product improvement, forming a virtuous cycle of technological iteration.