What are the symptoms of damage to the drive axle?

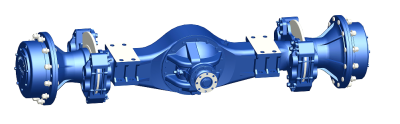

In the operation process of construction machinery, agricultural machinery and mining machinery, the drive axle is the core component of the transmission of power, and its operating state directly affects the operating efficiency and safety of the equipment.Once the drive axle is damaged, it may not only cause equipment downtime, but also cause safety accidents.As a powerful enterprise focusing on the research and development and production of drive axles, Shandong Lutong combines many years of industry experience to analyze the typical symptoms of drive axle damage in detail for you, and at the same time reveal the manufacturing code of high-quality construction machinery drive axles.

1.Abnormal noise: “Early warning” of drive axle failure

Abnormal noise is the most perceptible signal of damage to the drive axle, and abnormal noise in different scenarios often corresponds to different types of faults.During the operation of loaders, excavators and other equipment, if there is a “buzzing” sound when driving in gear, and the abnormal sound weakens or disappears when taxiing, it is mostly caused by the excessive meshing gap between the main reducer gear of the loader excavator drive axle; if the impact sound of “gra, gra” is made when turning, it may be caused by the poor meshing of the differential planetary gear and the half-shaft gear. The problem is caused by the poor meshing of the planetary gear and the half-shaft gear.

In view of this core pain point, Shandong Lutong has formed a technical team composed of more than 20 senior engineers to optimize the gear transmission system of the drive axle of construction machinery.Through accurate calculation of gear meshing parameters, high-precision gear grinding equipment is used to process bevel gears and cylindrical gears to ensure that the gear meshing gap of the loader excavator drive axle is controlled in the optimal range of 0.15-0.30mm, and the incidence of abnormal noise failure is reduced from the source.

2. Overheating: the “invisible killer” of core components

After the equipment has traveled for a period of mileage, it feels abnormally hot when touching the drive axle shell with your hand. This is a typical manifestation of overheating failure.Such problems are mostly caused by excessive bearing assembly, gear oil deterioration or too small meshing gap. Long-term overheating will accelerate the wear of gears and bearings and shorten the service life of the drive axle.In heavy-duty operation scenarios such as mining machinery, the problem of overheating is more prominent, and higher requirements are put forward for the heat resistance of the drive axle.

Shandong Lutong introduced bearing preload adjustment equipment imported from Germany to accurately control the bearing assembly strength through an automated system to avoid the problem of too tight or too loose.At the same time, the company has established strict oil testing standards, filled each construction machinery drive axle with suitable long-lasting gear oil, and conducted a no-load thermal run-in test for 2 hours before leaving the factory to ensure adequate lubrication of gears and bearings.In view of the heavy-duty characteristics of the loader excavator drive axle, the heat dissipation structure is additionally optimized to increase the heat dissipation efficiency by 30%.

3. Oil spills: “Safety hazards” of equipment operation

Obvious oil traces appear from the refueling port, oil seal or joint surface of the drive axle, which means that there is an oil leakage failure.Blockage of vent holes, aging of oil seals, or defects in bridge shell casting may all cause oil leakage, and gear oil leakage will directly lead to lubrication failure of internal components, causing chain damage.For outdoor operating equipment such as agricultural machinery, oil spills may also pollute the operating environment.

In order to completely solve the problem of oil leakage, Shandong Lutong uses floating oil seals and high-strength sealing liners, combined with three-dimensional scanning technology to detect the flatness of the joint surface of the bridge shell to ensure that the sealing fit reaches 99.8%.The company's drive axle production workshop is equipped with 12 CNC machining centers and three-dimensional coordinate testing equipment to perform full-size testing of bridge shell castings.Before shipment, each loader excavator drive axle needs to undergo a 48-hour hydrostatic sealing test to ensure that there is no leakage before it can be shipped out of the warehouse.

Choose the right drive axle to avoid the risk of failure from the root cause

Identifying the symptoms of drive axle damage is the key to equipment maintenance, and choosing a high-quality drive axle is the core of reducing the probability of failure.Shandong Lutong has been deeply engaged in the field of drive axles for more than ten years, and has a modern production base of 120,000 square meters with an annual production capacity of 30,000 units. Its products cover many fields such as construction machinery, agricultural machinery, and mining machinery.The company has established a full-chain quality inspection system of “raw material testing-production monitoring-finished product testing”, and all construction machinery drive axles have passed the ISO9001 quality system certification.

The company has established a full chain quality inspection system of "raw materials-production-finished products”:

Raw material link: The mechanical properties of each batch of steel and bearings are tested, and the unqualified raw materials are directly removed.;

Production link: Adopt MES production management system to monitor the machining accuracy of each process in real time to ensure product consistency;

Finished product link: All drive axles need to pass the three core tests of sealing test, no-load test, and loading test, and can be labeled and stored after passing the test.

Whether it is a loader excavator drive axle that responds to complex working conditions or a universal drive axle adapted to multiple scenarios, Shandong Lutong can provide customized solutions.From the design of the technical solution to the delivery of the product, the professional team follows up the whole process to ensure that each product can be adapted to the needs of the equipment.Choose Shandong Lutong drive axle to keep the equipment away from failure and improve operating efficiency.