Shandong Lutong Drive Axles: Batch Exports Empowered by Quality and Strength

With the accelerated advancement of agricultural modernization, infrastructure construction, and energy extraction industries, the engineering machinery, agricultural machinery, and mining machinery markets are demanding higher reliability and compatibility from core components. As a leading domestic Drive Axle manufacturer, Shandong Lutong has deep-rooted industry experience spanning over thirty years, focusing on the R&D and production of core components for machinery across multiple sectors. Recently, a batch of high-performance Tractor Drive Axles and Grader Drive Axles was successfully shipped to Russia. This shipment included specialized Drive Axles compatible with PTZ's 400-horsepower tractors and customized products for motor graders under the UMGA and Amkodor brands. Simultaneously, the newly developed Drive Axle for log skidders has been officially launched. With its comprehensive product portfolio and stringent quality standards, the company has become a trusted Drive Axle supplier in the Russian market.

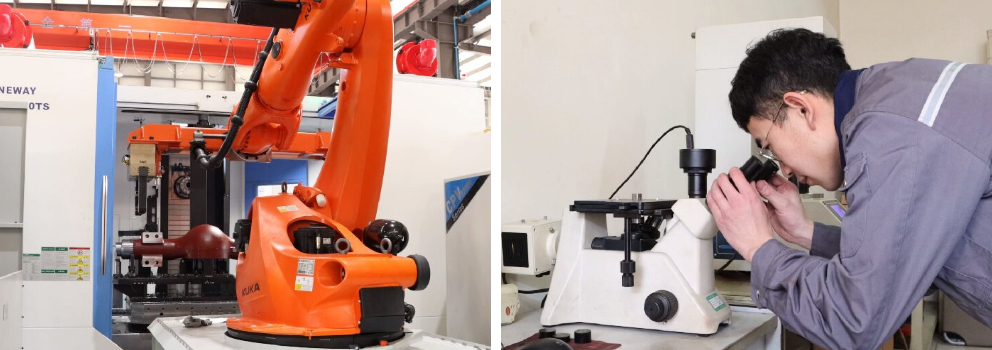

Technical Foundation: Core Strength Forged by Top Talent and Advanced Equipment

Shandong Lutong consistently regards technological R&D and production capability as its developmental cornerstone, establishing a fully integrated closed-loop system encompassing "R&D - Production - Testing." The company currently employs over 300 staff, with the R&D team accounting for more than 20%. Core technical personnel possess over 15 years of R&D experience in the Drive Axle industry, covering specialties such as mechanical design, materials engineering, and performance testing, and hold numerous national utility model patents.

The production workshop spans over 120,000 square meters and is equipped with internationally top-tier production and inspection equipment, including CNC machining centers imported from Germany, precision grinding machines from Japan, laser detectors, and coordinate measuring machines. This enables the fully autonomous machining of core components like Drive Axle housings and gears. By introducing an intelligent production management system, real-time monitoring and data traceability throughout the production process are achieved. The machining precision for key Drive Axle dimensions is controlled within ±0.005mm. With an annual production capacity exceeding 50,000 units, the company can meet the bulk order delivery demands from various global regions. Furthermore, the company has established an industry-leading Drive Axle performance testing laboratory capable of simulating extreme operating environments, providing comprehensive data support for product development and quality inspection.

Quality as the Core: Stringent Full-Process Control Bolsters Export Confidence

Adopting a "Zero Defects" quality objective, Shandong Lutong has established a full-lifecycle quality control system that far exceeds industry standards. Every process, from raw material procurement to finished product dispatch, undergoes layers of stringent inspection, ensuring every Drive Axle delivers exceptional reliability and durability.

During raw material procurement, the company has established strategic direct supply partnerships with leading domestic steel enterprises. All core materials undergo dual verification through material composition testing and mechanical property tests, eliminating potential quality risks at the source. Throughout the production process, 12 key quality inspection points are implemented, including component precision inspection, welding strength tests, and assembly gap calibration. Before dispatch, each Drive Axle must complete a continuous 72-hour load test run, a 100,000-cycle impact fatigue test, and high-low temperature cycle tests, ensuring it maintains the core advantages of stable transmission and low failure rates even under extreme conditions.

Currently, the company's products have passed ISO 9001 Quality Management System and ISO 14001 Environmental Management System certifications. Customer satisfaction for its Tractor Drive Axles and Grader Drive Axles in the Russian market has remained above 98% for three consecutive years. Recognized for their outstanding advantages of "cold resistance, wear resistance, strong load capacity, and long service life," they have become the preferred brand for local agricultural cooperatives and construction enterprises.

Product Portfolio: Precisely Meeting Diverse Scenario Needs

Leveraging strong R&D and production capabilities, Shandong Lutong has built a complete series of Drive Axle products covering engineering machinery, agricultural machinery, and mining machinery, accurately matching the operational requirements of different equipment models.

The PTZ 400-horsepower Tractor Drive Axles exported in bulk to Russia are specifically designed for the heavy-load operations on Russia's vast farmlands. Featuring a reinforced housing structure and high-precision spiral bevel gears, they offer a maximum input torque of 9,500 N·m and a load capacity 25% higher than similar industry products. They easily adapt to various agricultural tasks like deep plowing, seeding, and harvesting, effectively enhancing tractor operational efficiency and fuel economy. The Grader Drive Axles compatible with UMGA and Amkodor motor graders are optimized for transmission ratio design for scenarios like road construction and site leveling, achieving a transmission efficiency of up to 96%. Additionally, they incorporate floating oil seals at the wheel ends and wear-resistant coating technology, providing excellent dust and water resistance, making them suitable for the complex working conditions of Russian infrastructure projects.

The newly developed Drive Axle for log skidders focuses on forestry needs, innovatively using low-temperature adapted materials and impact-resistant design. It maintains good lubrication and transmission performance even in low-temperature environments, solving industry pain points like jamming and seal failure of traditional Drive Axles in extremely cold regions. Furthermore, the company has developed high-capacity Drive Axles for mining machinery and lightweight Drive Axles for compact agricultural machinery, forming a multi-dimensional, full-scenario product layout to meet the customized needs of different clients.

Service Escort: Efficient Fulfillment and Localized Support Earn Trust

Beyond exceptional product quality, Shandong Lutong's comprehensive supply chain and service system are crucial guarantees for its export business. The company has established a highly efficient service mechanism covering "Order Response - Production - Quality Inspection & Shipping - After-sales Support." For international markets, dedicated bilingual service teams and logistics support units have been formed, ensuring order response times do not exceed 24 hours and bulk order production cycles are 30% shorter than industry standards.

In the shipping phase, a "Customized Packaging + Strategic Logistics Partnership" model is adopted. Considering the characteristics of Drive Axle precision components, multi-layer packaging materials resistant to moisture, cold, and shock are used, incorporating cushioning devices and anti-rust treatments to ensure products remain undamaged during long-distance transport. Long-term partnerships with major logistics companies like Sinotrans and COSCO SHIPPING, along with dedicated transport channels, enable door-to-door delivery from the factory to the client's warehouse, with a stable delivery cycle of 15-20 days. Concurrently, the company has set up an after-sales service center staffed with professional maintenance engineers and ample spare parts inventory, capable of responding to client repair needs within 48 hours, providing comprehensive protection for the stable operation of its products.

In the future, Shandong Lutong will continue to focus on the core Drive Axle sector, persistently increasing R&D investment. Responding to evolving market demands in Russia and globally, it will optimize product performance and quality, expand into segments like mining machinery Drive Axles and intelligent agricultural machinery Drive Axles, and deepen cooperation with internationally renowned machinery brands. With stronger technical capabilities, stricter quality standards, and a more robust service system, Shandong Lutong aims to build a globally leading Drive Axle brand, providing core power for the global machinery industry upgrade.