Shandong Lutong Telehandler Drive Axles: Powering Jiubang's Success

In the engineering machinery industry, the drive axle serves as the equipment's "power core," whose reliability directly determines the machine's operational efficiency and operating costs. Jining Jiubang Engineering Machinery Co., Ltd., a prominent engineering machinery enterprise in the region, is fully launching a new series of telehandlers. This new product is central to its market expansion strategy, consequently demanding extremely stringent quality standards for core components. During the selection process of drive axles for this new product, significant issues emerged with previously considered telehandler drive axles, which frequently failed under heavy-duty conditions. Relying on over thirty years of technical expertise in the engineering machinery drive axle field, Shandong Lutong Machinery Technology Co., Ltd. provided a customized telehandler drive axle solution. This solution not only passed rigorous vehicle mounting tests but also earned the deep trust of Jining Jiubang, initiating a lasting partnership that continues today.

Customer Challenge: Breaking the "Bottleneck" of Drive Axles in Heavy-Duty Applications

Jiubang's newly developed telehandler integrates lifting, transporting, and stacking functions. Designed specifically for complex working conditions, it is planned for widespread use in scenarios like warehouse logistics, construction projects, and agricultural production. As a core new product for the market, Jiubang set performance stability standards far exceeding conventional industry levels. The drive axle, being the "power heart", saw its load capacity, impact resistance, and compatibility become key factors determining the new product's competitiveness. The previously considered drive axle products revealed shortcomings during initial testing: the axle housing was prone to stress concentration when carrying loads on gradients; operation required shutdown for cooling after 4 continuous hours to prevent oil leaks; insufficient steering flexibility also limited operational precision in confined spaces. These issues directly threatened the new product's market reputation, creating an urgent need for a high-performance drive axle.

To ensure the new product would lead the market upon launch, Jining Jiubang initiated a high-standard drive axle supplier selection process. The core requirements directly addressed the product's pain points: 1) The drive axle must handle 10-ton loads and climb 15° grades stably under heavy load without failure; 2) Excellent heat dissipation to support over 8 hours of high-intensity operation; 3) Precise compatibility with the new product's chassis to avoid major modifications delaying the launch cycle. After comparing multiple proposals, Shandong Lutong's targeted engineering machinery drive axle solution and extensive R&D experience successfully placed them within Jiubang's core consideration.

Customized Solution: Solving Dual Challenges of Compatibility and Performance with Technological Innovation

Upon receiving the requirements, Shandong Lutong immediately formed a dedicated technical team to conduct an in-depth, two-week on-site investigation at Jining Jiubang. Focusing on the new product's R&D data, the team analyzed the chassis structure and power transmission parameters, and simulated target working conditions to record load, speed, and temperature curves. This culminated in a customized drive axle solution centered on "Precise Compatibility and Performance Enhancement."

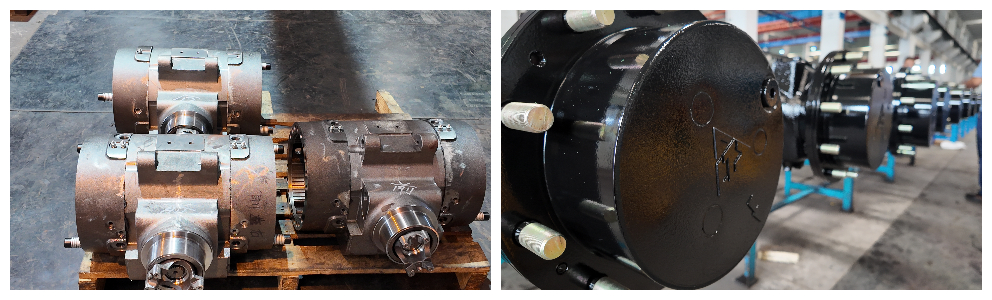

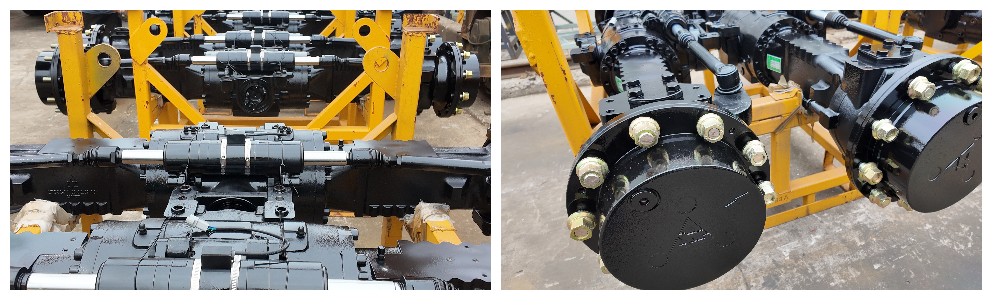

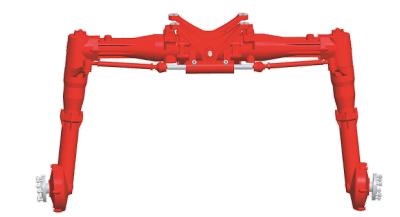

In core structural design, Shandong Lutong implemented three major optimizations for Jiubang's needs: 1) The axle housing was manufactured from high-strength alloy material. Finite Element Analysis (FEA) was used to apply localized thickening at the 6 o'clock position prone to stress, increasing this engineering machinery drive axle's maximum load capacity to 12 tons, exceeding the client's 10-ton requirement and effectively dispersing stress to prevent cracking risk. 2) The cooling system was upgraded to maintain the drive axle temperature below 85°C during continuous operation, ensuring no overheating during 8-hour high-intensity work. 3) The steering knuckle structure was optimized using high-precision gear meshing design, improving steering response speed by 20% and significantly enhancing operational flexibility in tight spaces, making the overall performance of this telehandler drive axle superior.

Furthermore, to reduce modification costs for Jining Jiubang, Shandong Lutong strictly matched the drive axle's mounting interfaces and dimensional parameters to the existing chassis structure. Only minor adjustments to the connecting brackets were needed, achieving a "plug-and-play" compatibility effect and shortening the product integration timeline.

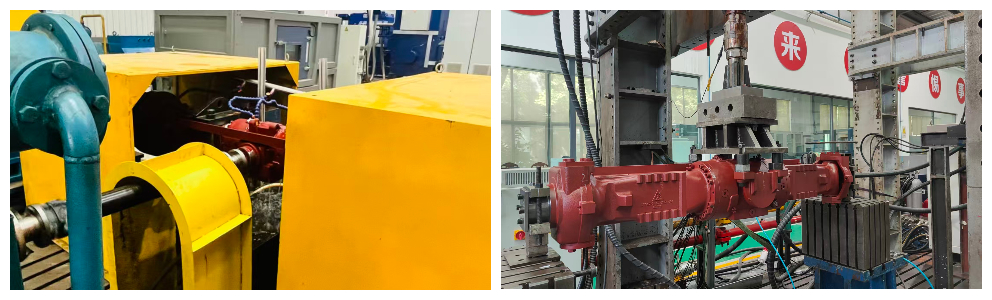

Vehicle Mounting Test: The Quality "Report Card" Under Stringent Validation

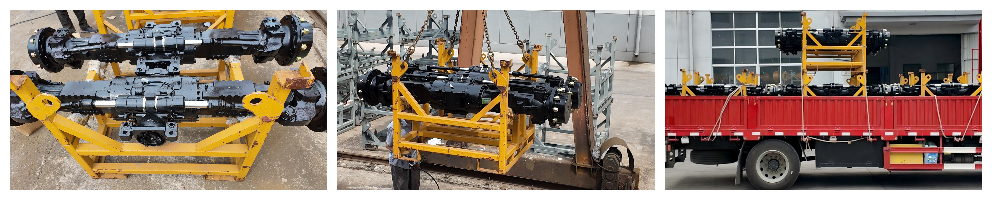

In September 2025, the first batch of telehandler drive axles custom-built by Shandong Lutong for Jiubang's new product were formally delivered. Centering on the new product, both parties initiated a month-long vehicle mounting test covering typical conditions like warehousing, construction, and field operations. Jiubang's technical and production departments supervised the entire process. The test results far exceeded expectations, solidifying the foundation for the new product's launch.

During heavy-load performance tests, the telehandler equipped with Shandong Lutong's telehandler drive axle continuously performed 15° grade climbs with 10-ton loads for 3 consecutive days, operating 10 hours daily. Post-test teardown inspection revealed no stress cracks in the axle housing, gear wear was only one-third of the industry standard, and oil temperature remained stable at 78°C. In complex terrain tests, after driving 200 km on muddy and gravel-mixed roads, the sealing performance of this engineering machinery drive axle remained intact, with no oil leaks or dust ingress. In compatibility tests, the drive axle perfectly matched the existing power system, increasing power transmission efficiency by 15% while reducing overall fuel consumption by 8%, further enhancing the product's market competitiveness.

"This set of test data completely eliminated our concerns. Shandong Lutong's drive axle not only solved the core challenges of our new product but also gave it advantages in efficiency and fuel consumption," commented Jining Jiubang's Production Director during the test summary meeting. Following the test conclusion, both parties immediately signed the first procurement contract for the Telehandler Drive Axles, paving the way for mass production and officially commencing their cooperation.

Long-Term Cooperation: Building a Win-Win Partnership Based on Quality

To date, the cooperation between Shandong Lutong and Jining Jiubang continues stably. With the enthusiastic market response to Jiubang's new product, the cumulative supply of telehandler drive axles has reached over 30 units. During this period, Shandong Lutong established a dedicated after-sales service team, conducting regular on-site maintenance checks and performance adjustments. Based on Jining Jiubang's new product iteration needs, they have simultaneously optimized the drive axle's technical parameters, fully supporting its product upgrade plans and ensuring the compatibility between the core component and the host machine remains optimal.

Jiubang's new telehandler, equipped with Shandong Lutong's drive axle, quickly gained a reputation as the "Durability King" post-launch, with sales exceeding expectations by 40%. Through the cooperation with Jiubang, Shandong Lutong gained deep insight into the working condition demands of the new generation of telehandlers, refined its related drive axle product system, and accumulated valuable experience for serving more engineering machinery enterprises.

Cooperation Insight: Quality is the Best "Bond of Cooperation"

In today's increasingly competitive engineering machinery industry, the collaboration between suppliers and clients has transcended simple "supply-demand relationships," evolving into "value co-creation" based on quality recognition. The partnership case between Shandong Lutong and Jining Jiubang demonstrates that only by deeply understanding the client's core pain points, leveraging technological innovation to create drive axle products that meet practical needs – especially high-performance telehandler drive axles and engineering machinery drive axles – and demonstrating quality capability through stringent test validation, can a supplier earn a client's long-term trust.

Looking ahead, Shandong Lutong will continue to focus on the R&D and production of engineering machinery drive axles, agricultural machinery drive axles, and mining machinery drive axles. Aiming to empower more enterprises like Jining Jiubang with superior drive axle products and more professional service, Shandong Lutong strives for mutual growth and win-win outcomes in the global market.