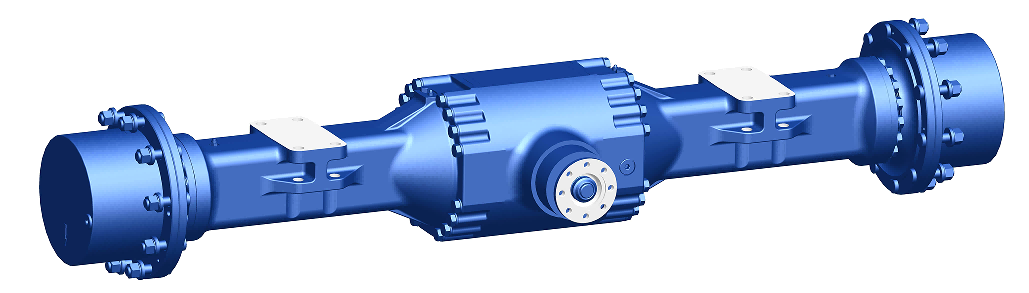

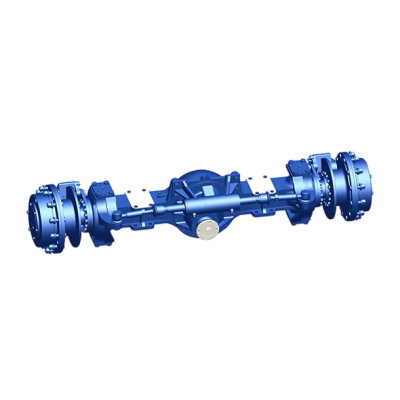

Wheeled Wet Spraying Machine Axle

1.Supports customization for non-standard specifications.

2.High transmission efficiency reduces overall fuel consumption.

3.High annual production capacity handles seasonal order surges.

4.Allows on-site witness of quality inspection processes.

Introduction:

Wheeled Wet Spraying Machine Axle is a high-performance drive axle assembly developed for harsh underground working conditions, demonstrating exceptional overall performance in practical applications. The drive axle possesses robust load-bearing capacity, fully capable of withstanding the intense loads generated during heavy-duty operations such as concrete spraying. Its core transmission components feature reinforced designs for heavy-duty conditions, significantly enhancing fatigue resistance and durability, thereby effectively extending the gear system's service life.The gear ratios of the main reducer assembly and wheel-end reducer assembly are scientifically matched and optimized, ensuring not only smooth and efficient power transmission but also enhancing the reliability of the entire drivetrain under impact and vibration conditions, adapting to variable underground workloads.For the damp, contaminant-rich underground environment, the sealing system of the Wheeled Wet Spraying Machine Axle assembly is specially designed. The oil seals employ a multi-layer protection structure, while critical piston seals are made of high-temperature and high-pressure-resistant materials, greatly improving sealing reliability and effectively preventing the intrusion of external moisture, dust, and other contaminants to protect internal transmission and braking components.

The axle housing is manufactured from high-strength nodular cast iron, offering excellent rigidity and impact resistance. It withstands continuous heavy loads while effectively resisting shocks and vibrations from complex underground terrain, ensuring long-term structural stability of the Wheeled Wet Spraying Machine Axle assembly. As the core load-bearing and force-transmitting component of the wet spraying machine, this wheel axle handles the machine's primary loads while delivering massive torque, providing strong and stable traction to fully meet demanding operational needs such as heavy-duty uphill climbing and high-speed transit underground.The braking system utilizes multi-disc wet brakes fully enclosed within the axle housing, eliminating oxidation and potential spark risks associated with air exposure. This design not only better adapts to underground environments but also significantly enhances braking safety and service life. The hydraulically actuated system responds rapidly with sufficient braking torque, ensuring reliable and timely stopping on slopes, curves, and other extreme conditions to protect both personnel and equipment.

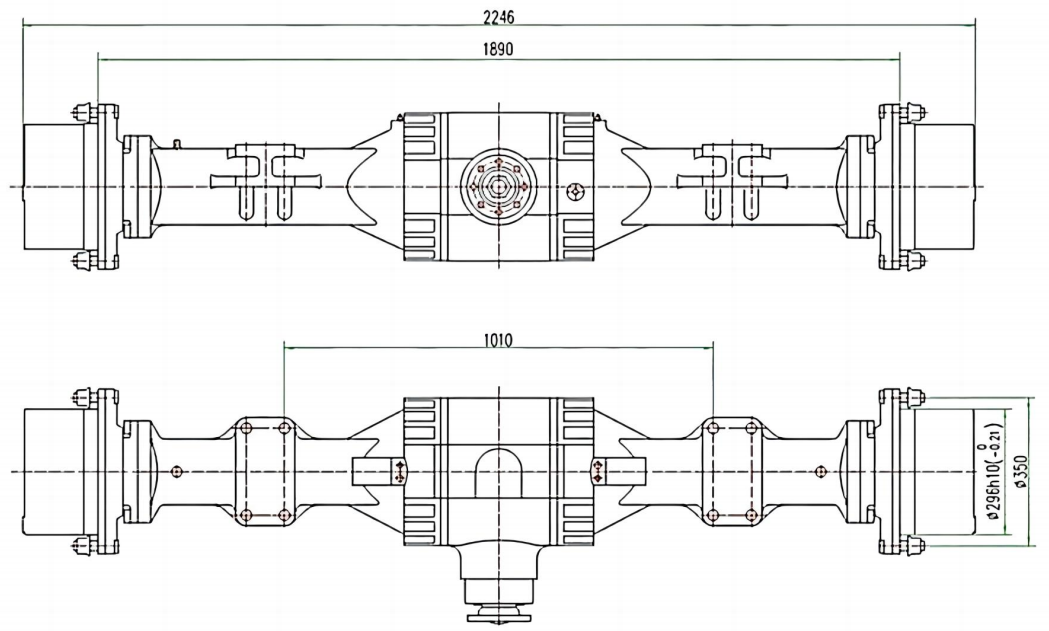

Main technical parameters:

Total transmission Ratio | 16.91 |

Maximum 0utput torque | 50000N.m |

Dynamic load each axle | 15000Kg |

Braking torque(single side) | 21000N.m |

Braking oil pressure | 4Mpa |

Braking displacement | 45-128ml |

oil request for driving axle(API standard) | GL-5:85W/90 Gear oil(above -12 ℃) |

Brake and cylinder oil | L-HL46hydraulic oil |

Application Scenarios

Developed by incorporating advanced technologies from domestic and international engineering machinery drive axles, the Wheeled Wet Spraying Machine Axle features reinforced components in its wheel-end reduction assembly to better suit domestic underground working conditions. It is compatible with underground specialized vehicles like wet spraying machines and drilling jumbos, as well as engineering vehicles such as wheeled excavators.

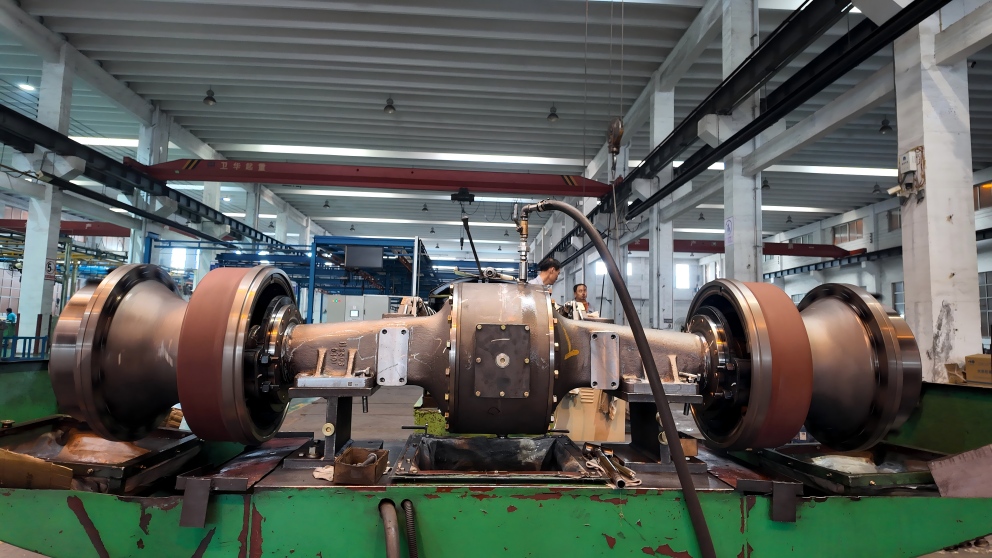

Production System

The production system for the Wheel Axle consistently focuses on high reliability, consistency and adaptation to harsh underground conditions. Manufacturing strictly follows process specifications throughout. Upon arrival, castings like axle housings undergo comprehensive quality inspections. We examine not only appearance and dimensions but also use non-destructive testing to identify potential defects like internal shrinkage and cracks, ensuring no substandard materials enter production.During machining, key components are processed on dedicated production lines using specially developed fixtures and tooling. This approach minimizes human operational variability, ensuring precision and interchangeability of critical features such as main reducer mounting holes and wheel-end support seats, guaranteeing product consistency from the manufacturing source.

The assembly phase reflects advanced process maturity. We employ a range of specialized assembly tools to achieve damage-free assembly. For instance, when pressing interference-fit components like oil seals and bearings, guide tools prevent misalignment, ensuring proper placement without damaging sealing lips or rolling elements. For critical bolt connections, professional tools like torque wrenches are used to precisely control preload force, ensuring connection reliability while avoiding thread or part damage from overloading.After full assembly, bench testing typically simulates actual operation to comprehensively validate sealing performance, braking function, and transmission smoothness, ensuring every axle meets design standards before delivery. This closed-loop quality management—from raw material control and precision machining to standardized assembly—enables this drive axle to consistently provide customers with stable and durable power transmission solutions.