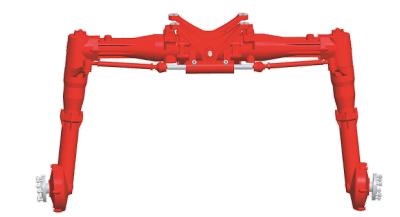

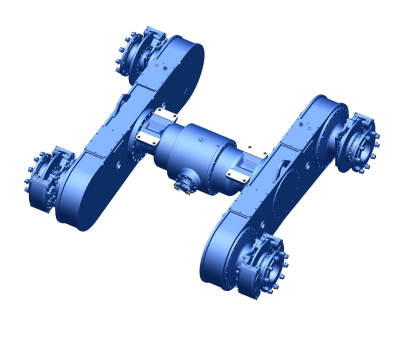

Shandong Lutong Launches New Harvester-Skidder Axle: Redefining Reliability Standards in Forestry Equipment with Ultimate Craftsmanship

In the forestry and heavy-duty off-road equipment sector, the performance of the drive axle is pivotal to the durability and efficiency of machinery. Shandong Lutong, a leading manufacturer of drive axles, has officially launched a new dedicated drive axle for logging skidders. By integrating top-grade materials with precision engineering, it delivers a robust solution for high-intensity operational environments.

Core Advantages: End-to-End High Standards from Components to Assembly

1. Internationally Certified Bearings Extend Service Life:

Critical bearings employ European-imported, high-load brands, enhancing impact resistance by 30%. They maintain low friction and high rotational precision even under extreme conditions, significantly reducing maintenance frequency.

2. Forged Axle Tube + Floating Oil Seal: Dual Pressure Defense:

Axle tubes utilize multi-directional forging, resulting in continuous, dense internal metal grain structure. This increases bending resistance by 50% compared to standard cast parts.

The floating oil seal design combats the forestry environment's high dust and humidity, achieving a seal life exceeding 8,000 hours and eliminating oil leakage risks.

3. High-Grade Housing & Precision Machining:

The housing is made of high-strength ductile iron. Machined on 5-axis CNC centers, it ensures gear meshing surface tolerance within ≤0.02mm. Combined with refined torque assembly processes, vibration and noise are reduced to industry-leading levels.

4. Rigorous Sealing Test System:

Multiple cavities undergo comprehensive sealing tests, conducting continuous thermal cycling from -40°C to 80°C, to achieve

a 100% zero-leakage qualification standard before leaving the factory.

"The design phase of this product focused squarely on the 'brutal operating conditions' of forestry machinery," stated Shandong Lutong's Technical Director. "We conducted destructive testing using parameters exceeding national standards, such as a continuous 72-hour full-load logging simulation. The results proved its reliability far surpasses customer expectations."

This drive axle has already passed joint acceptance tests by forestry equipment manufacturers in Russia, Southeast Asia, and other regions, and is poised for mass delivery. Shandong Lutong remains committed to driving the advancement of core components for heavy machinery, guided by the principle of "Zero Compromise on Materials, Zero Defects in Craftsmanship."