High Efficiency, Precision, and Reliability – How Shandong Lutong Tooling Technology Empowers Drive Axle Performance Enhancement

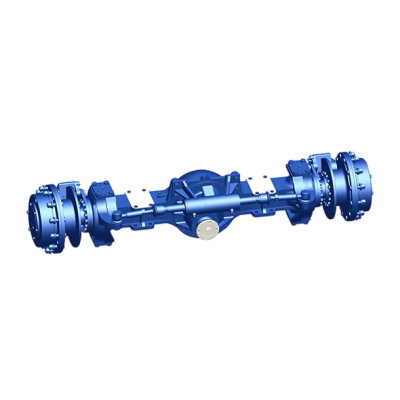

In the field of construction machinery, the drive axle, as a core transmission component, directly impacts the overall operating efficiency of equipment through its performance and reliability. As a leading manufacturer of construction machinery drive axles, Shandong Lutong continuously drives industry technological advancement with advanced tooling technology and extensive production experience. This article will take you into the world of Shandong Lutong tooling, exploring how we enhance the manufacturing precision and production efficiency of drive axles through specialized tooling solutions.

Core Advantages of Shandong Lutong Tooling Technology: Professionalism, Efficiency, Stability

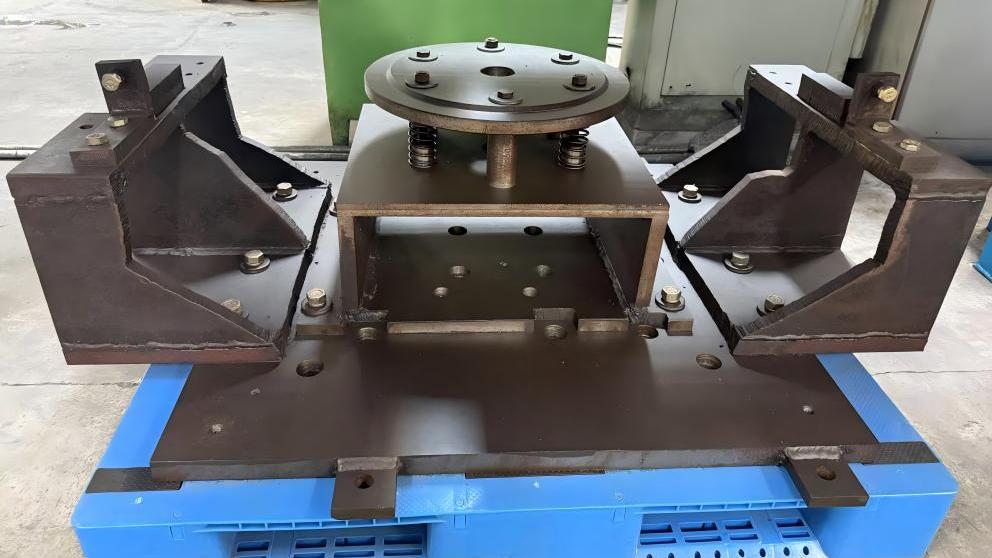

Tooling is a critical guarantee in the drive axle production process. Shandong Lutong possesses a large, specialized tooling storage area, equipped with hundreds of sets of high-precision tooling covering the entire process from machining and inspection to assembly. Our tooling technology boasts the following distinct features:

High-Precision Positioning Design: Tooling tolerance is strictly controlled within ±0.02mm (±0.0008 in), ensuring perfect fitment of key components like gears and bearings.

Modular Quick Changeover: Provides flexible, adaptable tooling systems for different drive axle models, reducing die change time by over 50%.

Industry-Leading Tooling Technology Applications

Leveraging professional tooling expertise, Shandong Lutong provides comprehensive process equipment support for the manufacturing of various construction machinery drive axles. Our tooling solutions significantly enhance production efficiency and product quality:

Increased Assembly Efficiency: Optimized tooling systems shorten single-unit assembly cycles, enabling more efficient mass production.

Enhanced Quality Stability: Precision tooling ensures assembly accuracy of critical components, effectively reducing product defect rates.

Improved Product Reliability: Drive axle assemblies optimized through tooling demonstrate superior performance in durability and service life.

Demonstrating Tooling Advantages in Actual Production

Our tooling technology has demonstrated significant value in multiple application scenarios:

Providing quick die change solutions to meet flexible production needs for different drive axle models.

Improving the fitment accuracy of key components through tooling optimization.

Offering customized tooling support for drive axles with special operating condition requirements.

Latest Development Directions in Shandong Lutong Tooling Technology

With the advent of the intelligent manufacturing era, Shandong Lutong is accelerating the intelligent upgrade of its tooling technology:

Digital Simulation Design: Utilizing 3D modeling and Finite Element Analysis (FEA) to optimize tooling structure, enhancing adaptability and durability.

Durability Material Optimization: Employing high-strength alloy steel and wear-resistant composite materials for core tooling. This extends service life by over 2 times while ensuring positioning accuracy, meeting the heavy-duty machining requirements of construction machinery parts.

Conclusion:

Shandong Lutong firmly believes that exceptional tooling technology is the cornerstone of manufacturing high-quality drive axles. Moving forward, we will continue to deepen tooling R&D, providing customers with more efficient and reliable drive axle solutions, and empowering the global construction machinery industry to reach higher levels.