How Technological Innovation of Drive Axles Reshapes Performance Benchmarks of Modern Articulated Tractors

The Story of Articulated Tractor Development

Tractors, as the heart of farm mechanization, have always gotten a lot of attention as they’ve developed.Early tractors had a stiff frame design. They could put out basic power, but they weren’t great at moving easily or adapting to different fields. Especially when working in tricky terrain or narrow plots, old-style tractors often couldn’t keep up. This problem got worse in the mid-20th century: as farms got bigger,people started asking a lot more from their farm machines.

It was in this context that Elmer Wagner proposed the new idea of articulated tractors in 1949. The key to this design was putting a hinge in the middle of the tractor, so the front and back frames could turn relative to each other. That made the whole machine much easier to maneuver. The first articulated tractors used simple mechanical steering—their design was basic, but they already worked a lot better than old tractors.

Then hydraulic technology came along, and that changed articulated tractors for good. In the 1960s, hydraulic systems started being used widely in farm machines, giving articulated tractors more precise and reliable steering control. Around this time, many well-known farm equipment companies put money into research and development, which made articulated tractor tech improve fast.

When the 21st century hit, electronic control tech got better too—and articulated tractors started becoming smarter. Today’s articulated tractors don’t just have great mechanical performance; they also have advanced sensors, control systems, and info management tools. They’re real “smart” farm machines now.

How Articulated Tractors Are Built and How They Work

An articulated tractor is an innovative farm machine with a pivot hinge in the middle of its body. The main thing that makes it different? It steers by the front and back frames turning relative to each other—a design that gives it advantages no old-style tractor can match.

Articulated tractors have some big advantages that make them irreplaceable in modern farming. Here’s what sets them apart:

First, they’re easy to maneuver. Because of the articulated steering, their turning radius is 30% to 40% smaller than old tractors with the same wheelbase. That means they can move easily in narrow fields or tricky terrain—perfect for big farms. In real use, this saves time on turning at the end of rows and keeps farming work moving smoothly, which makes work faster.

Second, they’re better for soil. When old tractors turn in fields, the front wheels have to turn a lot—this crushes and damages the soil. Articulated tractors steer as a whole, so their tire tracks are more even. That means they compact the soil a lot less. Studies show that under the same conditions, articulated tractors compact soil 20% to 30% less than old tractors. That’s really important for keeping soil healthy and fertile.

Third, they pull harder. Articulated tractors have a more balanced weight distribution—front and back axles carry weight almost perfectly. Plus, they have a low center of gravity. This lets them pull harder while staying stable. This is especially helpful when working on soft soil or hills. Tests show that with the same engine power, articulated tractors are 15% to 25% more efficient at pulling than old tractors.

Fourth, they’re versatile. Modern articulated tractors have lots of places to hook up tools and hydraulic ports. They can work with all kinds of farm equipment—plows, seeders, cultivators, harvesters, and even trailers. Some high-end models have quick-hitch systems, so you can switch tools in just a few minutes. That means the tractor gets used more, instead of sitting idle.

Of course, articulated tractors have some challenges. Their design is more complex, so they cost more to make and fix. The hydraulic system needs regular maintenance, which means operators need to know how to take care of it. And when the tractor is carrying heavy loads, steering might not be as precise. But these issues can be fixed with more tech improvements.

Why Drive Axles Matter and How They’re Changing

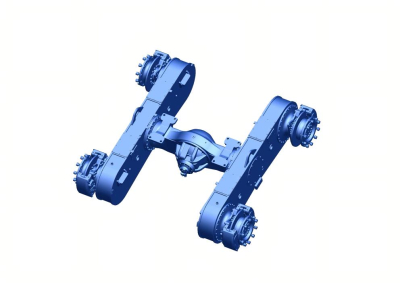

The drive axle is the most important part of an articulated tractor. How well it works determines how well the whole tractor works—and how reliable it is. A good tractor drive axle doesn’t just move power efficiently; it also has to carry heavy loads, be tough, and adapt to different conditions.

What Makes Our Innovative Drive Axles Special

Our company has over 30 years of experience making drive axles for construction machinery. We used that know-how to build a line of high-performance drive axles just for high-horsepower articulated tractors. These axles use our best tech in materials, design, and manufacturing—so they work great and last a long time.

When it comes to matching power, our drive axles use a modular design. That means they can work with tractors of different power levels. Right now, our axles fit tractors from 350 to 430 horsepower—perfect for heavy farming work. The transmission parts use optimized helical gears, which move power with over 96% efficiency. That means almost no power is wasted.

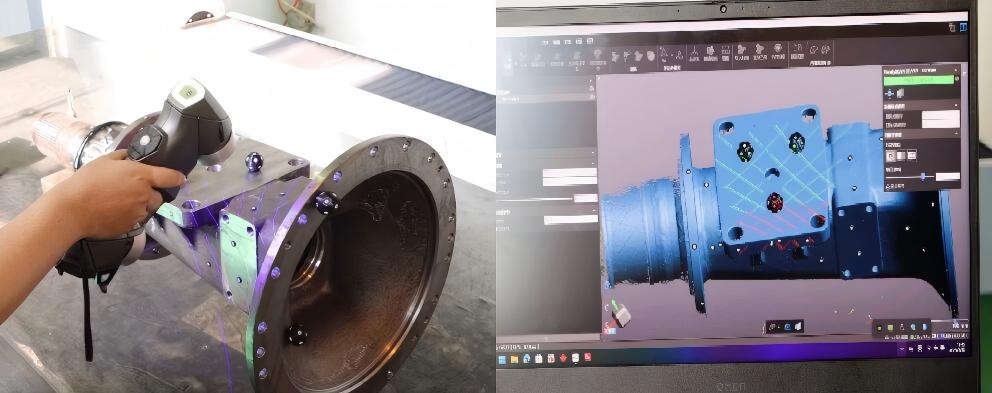

For design, we use finite element analysis (a computer tool that checks strength) to make the axle housing as light as possible—without losing strength. The axle housing is made of high-strength cast steel and goes through special heat treatment, so it’s stiff and can handle impacts. The parts that hold bearings are reinforced, so they stay accurate even when carrying heavy loads.

For seals, we made a multi-layer composite seal system. The main shaft uses a double-lip oil seal—this seals better and lasts longer. The end covers use a labyrinth design plus a rubber seal to keep mud and water out. The ventilation system is waterproof, so the drive axle works even when it’s in water.

Our drive axles also have space for adding smart features. You can easily install temperature sensors, oil level sensors, or vibration sensors. This gives you the hardware you need for predictive maintenance (fixing problems before they happen) and smart management later on.

Real-World Uses and What Customers Say

Our drive axles are used in many countries around the world—especially in places where farming conditions are tough. They’ve proven they work well and are reliable.

In Siberia, Russia, a big farm uses articulated tractors with our drive axles. Siberia has brutal weather: winter temps drop to -40℃, and spring brings muddy fields after the snow melts. The farm’s mechanical supervisor said the tractors start easily even in the cold, and the drive axle oil flows well even at low temps. During spring planting, the tractors work over 18 hours a day—and the drive axles never break down.

In Northeast China, many large state-owned farms use our drive axles too. These farms have huge fields, and the planting and harvesting seasons are short—so equipment has to be reliable. The farm’s machinery managers said our drive axles handle heavy work easily, and they last over 10,000 hours—way more than expected. Taking care of them is easy too: just check the oil level regularly and change the oil when needed.

These real cases show our drive axles are reliable and adaptable. Customers usually say four things about them:

They’re reliable—hardly any breakdowns.

They’re easy to maintain—long intervals between service.

They adapt well—work in all kinds of tough conditions.

They last long—good return on investment.

What’s Next for Drive Axle Tech

As farm machinery gets smarter and more sustainable, articulated tractors and their key parts (like drive axles) are going to change even more. As a drive axle maker, we’re watching these trends closely—and working on new tech and products.

Smarter axles are a big trend. We plan to put more sensors and smart control units in our next-gen drive axles:Temperature sensors to track oil temp in real time、vibration sensors to check how gears and bearings are doing、oil quality sensors to make sure the oil is still good and lighter axles are another trend. We’re testing new materials like composites for axle parts—these are strong but light. We’re also using topology optimization (a design tool that removes unnecessary material) to make structures more efficient. This will make axles lighter without losing strength.

Manufacturing tech is changing too. Additive manufacturing (3D printing) will revolutionize how we make drive axles. 3D printing can make complex parts that are hard to make with old methods—and that means parts can do more. Digital Twin tech (a virtual copy of the axle) will let us test designs and manufacturing steps in a computer first. That will speed up development and make axles better.Sustainability is important too. We’re working on making drive axles more eco-friendly:Using biodegradable oil、using surface treatments that don’t harm the environment and making axles easier to recycle.

We’re also looking into energy recovery—turning the energy from braking into electricity to store. That will make tractors more efficient.In the future, we’ll keep working with tractor makers to improve articulated tractor tech. By keeping innovating, we’ll make drive axles that are more efficient, reliable, and eco-friendly for farms everywhere—and help keep global food supplies secure.