What Are the Consequences of Drive Axle Failure?

The drive axle serves as the "power bridge" for construction machinery, agricultural equipment, and mining vehicles. Among these, drive axles for construction machinery are the core power transmission units, responsible for accurately transferring engine torque to the wheels. Failure of this critical component does more than just halt operations—it directly compromises worksite safety, delays production schedules, and significantly increases operating costs. Below, we detail the early warning signs of drive axle failure, its ripple effects, and how qualit wheel excavator drive axles manufacturing mitigates these risks at the source.

Early Warning Signs: How to Identify Drive Axle Failure

Drive axle deterioration is a gradual process, and equipment typically emits clear warning signals before complete failure. While symptoms vary across machinery types, common indicators exist—particularly in frequently used equipment such as loaders and wheeled excavators:

Symptoms in Construction Machinery (Loaders, Wheeled Excavators, etc.)

Abnormal Noises: Clunking or grinding noises during operation often indicate differential gear wear or bearing damage. In loader drive axles—frequently subjected to heavy loads and repeated starts—excessive gear backlash can cause pronounced noise during initial shoveling movements. For wheel excavator drive axles which alternate between travel and digging modes, planetary gear wear may produce high-pitched whining during mode transitions.

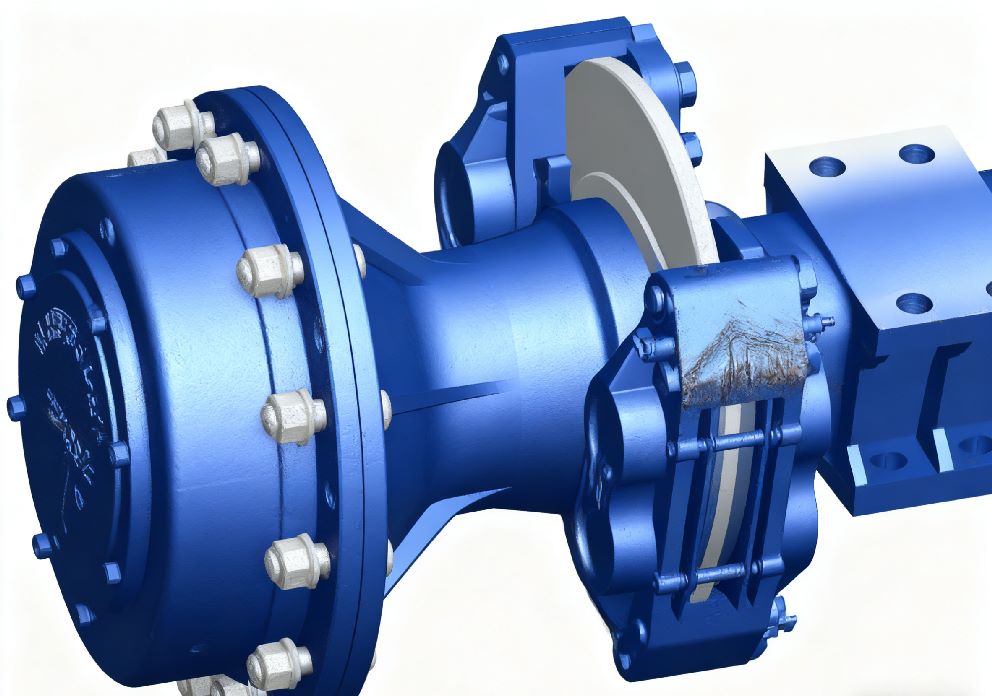

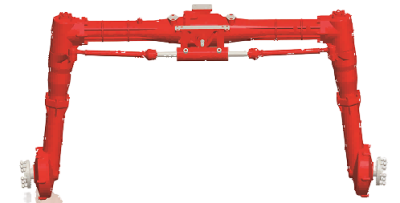

Steering Malfunctions: Difficult steering or uneven wheel rotation often points to differential lock failure. Wheel excavator drive axles operating on complex terrain may exhibit jerky steering if the differential lock sticks—severely impacting operational precision. Shandong Lutong's drive axles for construction machinery series address this with integrated hydraulic differential locks, using precise oil pressure control to prevent failures under high-frequency use in loaders and wheeled excavators.

Oil Leaks: Oil stains beneath the axle indicate seal damage, allowing sand, dust, or mud to infiltrate the system. Loader drive axles in dusty environments experience accelerated seal wear. Lutong's drive axles for construction machinery feature upgraded sealing structures that effectively block contaminants, making them ideal for wheeled excavators operating in dynamic outdoor conditions.

Symptoms in Agricultural and Mining Machinery

Wheel Slippage: Poor acceleration response in farm tractors or mining trucks may stem from worn wheel-end gears. Shandong Lutong's axles for 380–430 hp tractors utilize NGW planetary reduction for stable power transfer, while mining axles employ reinforced wheel-end gears to handle heavy-load demands.

Severe Vibration: Intense shaking at high speeds often results from bent axle shafts. Lutong axles employ high-strength alloy housings with superior rigidity to prevent such issues, ensuring stable performance whether in farm tractors or mining trucks.

Ripple Effects of Drive Axle Failure

Ignoring early warnings can trigger a chain reaction of problems, particularly in applications reliant on drive axles for construction machinery:

Productivity Loss: Axle failure directly idles equipment—costing mining operations over $1,000 daily. In construction sites, failed Loader or wheel excavator drive axles delay subsequent work phases. Shandong Lutong's annual production capacity of 50,000 axles (over 60% dedicated to drive axles for construction machinery) enables rapid replacement for loaders and wheeled excavators, minimizing downtime.

Safety Risks: Sudden axle failure may cause equipment drift. In confined worksites, steering failure in wheeled excavators can lead to collisions. Lutong's drive axles for construction machinery feature wet disc brakes that provide reliable emergency stopping power even under heavy loads or slippery conditions.

Secondary Damage: Axle issues can damage transmissions and tires. A seized differential in loader drive axles may overload and fracture the transmission output shaft. Shandong Lutong's "Integrated Drive Axle-Transmission Solution" for construction machinery uses precision gearing to reduce inter-component wear and impact, lowering secondary failure risks.

Prevention: Shandong Lutong's Product Strengths

With over 30 years of specialization, Shandong Lutong has refined its drive axles for construction machinery to address core challenges in Loader and wheel excavator drive axles:

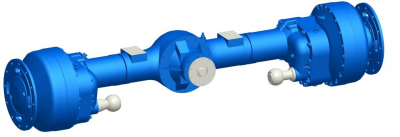

Durable Components: The ZL50 Loader Drive Axle uses Gleason spiral bevel gears with high-precision grinding to reduce noise and wear by 40%. Wheel loader drive axles excavator drive axles incorporate reinforced planetary carriers to withstand frequent torque shocks from steering.

Intelligent Manufacturing: Automated welding lines and coordinate measuring machines achieve 0.001-mm precision, ensuring consistent gear clearance and sealing in drive axles for construction machinery for high-intensity loader and excavator applications.

Scenario-Specific Designs: Custom axle series include reinforced housings for loaders and lightweight differentials for excavators. The range extends from 105-ton mining truck axles to 4-stage reduction forestry axles, all tailored to operational demands.Operator Response Measures

If any warning signs appear in loaders, wheeled excavators, or similar equipment, cease operation immediately for inspection. Shandong Lutong's global service network offers diagnostic support for drive axles for construction machinery—whether on construction sites or farms. All our axles are ISO 9001 certified, with the drive axles for construction machinery series backed by warranty. To upgrade your failure-resistant drive axle system, contact us for customized solutions matching your loader, excavator, or other equipment models.

- Previous : China's Wide-Body Mining Trucks Forge Ahead, Breakthrough in Core Drive Axle Technology Builds the Backbone of Mine Haulage

- Next : Load Haul Dump Drive Axle: The "Power Core" Ensuring Efficient and Safe Operation of LHDs What is a Mining LHD? In the world of underground mining, characterized by confined spaces, harsh environments, and continuous operation, equipment faces extremely