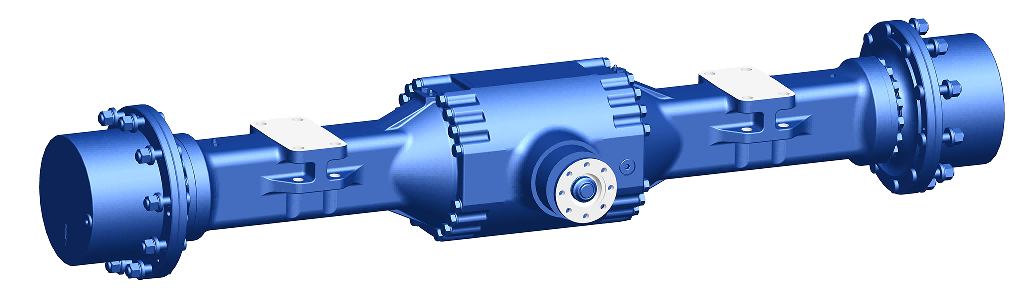

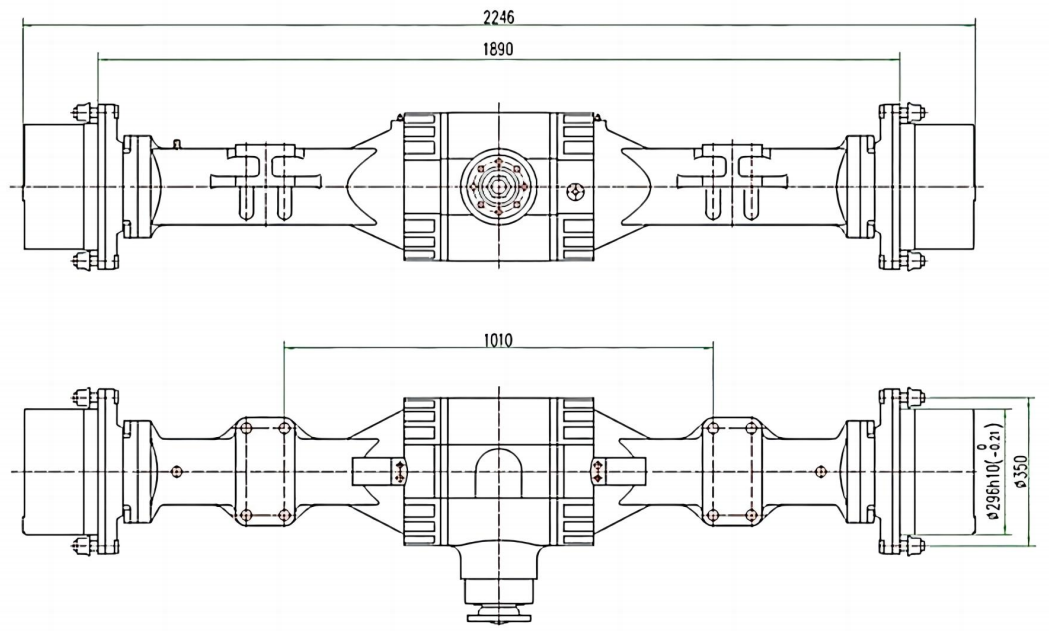

Rock Drilling Vehicle Axle

1. The main reduction mechanism makes use of Gleason spiral bevel gears, which not only boost transmission efficiency significantly but also cut down on operational noise remarkably. 2. At the wheel end, an “NGW type” planetary reduction structure is implemented. It is known for its space - saving design and carefully engineered structural setup. 3. The braking system is equipped with caliper disc brakes. These brakes generate substantial torque, ensuring consistent and trustworthy braking performance. 4. Thanks to the incorporation of hydraulic power - assisted steering, the equipment can be operated with ease and offers excellent maneuverability. 5. Constructed from solid cast steel, the axle housing exhibits exceptional load - bearing capacity and remarkable rigidity. 6. This setup is commonly mounted on 14 - 16 ton rock drilling vehicles, fitting their operational requirements well.

Introduction:

Tailored for 14 - 16 ton rock drilling vehicles, this machinery features Gleason spiral bevel gears in the main reduction, ensuring high - efficiency power transfer with minimal noise. The wheel end's “NGW type” planetary structure offers a compact and well - engineered design. Its caliper disc braking system provides ample torque for reliable stops, while the hydraulic power - assisted steering enables smooth maneuvering. The integral cast steel axle housing, boasting excellent load - bearing capacity and rigidity, further enhances its durability and performance in rugged drilling operations.

Main technical parameters:

Total transmission Ratio | 16.91 |

Maximum 0utput torque | 50000N.m |

Dynamic load each axle | 15000Kg |

Braking torque(single side) | 21000N.m |

Braking oil pressure | 4Mpa |

Braking displacement | 45-128ml |

oil request for driving axle(API standard) | GL-5:85W/90 Gear oil(above -12 ℃) |

Brake and cylinder oil | L-HL46hydraulic oil |