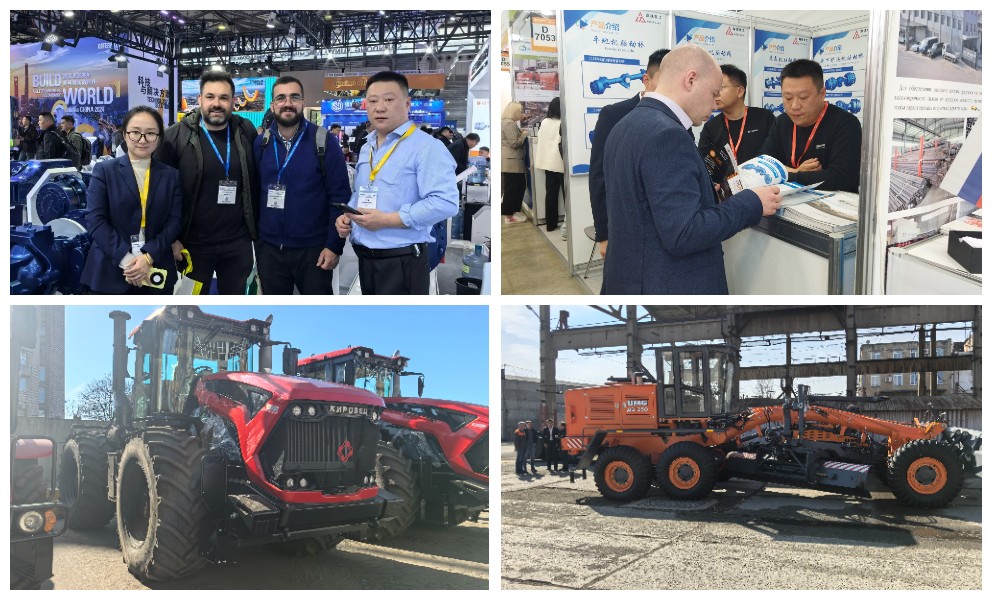

Belarusian Clients Visit Drive Axle Manufacturing Enterprise

International Clients' Inspection Highlights Company's Global Influence

Recently, a delegation of important clients from Belarus specially visited our company for an in-depth inspection and technical exchange. The clients not only highly praised the quality of our grader drive axles and loader drive axles provided but also expressed a strong willingness to deepen cooperation on-site. Beyond the market-proven products, preliminary cooperation intentions were reached for new products like the wheeled excavator drive axle. This visit fully demonstrates the exceptional competitiveness of our products in the international market and highlights the technical strength of "Made in China" in the core components sector.

The delegation visited our intelligent machining workshop, assembly production line, and product testing center. During the tour, the clients paid particular attention to the production process of the grader drive axle, conducting a detailed review of every step from axle housing welding and forming to gear precision machining, and from component quality inspection to final axle assembly and debugging. The clients' technical expert stated, "We have personally witnessed your company's stringent quality control system, which gives us great confidence in deepening our cooperation."

As an enterprise specializing in the R&D and manufacturing of engineering machinery drive axles for over thirty years, our company has always regarded product quality as our lifeline. This visit by the Belarusian clients is not only recognition of our product quality but also an affirmation of our comprehensive corporate strength. During the technical exchange, both parties held in-depth discussions on product adaptability under local specific working conditions, providing valuable first-hand data for subsequent product

optimization and upgrades.

Strength Witnessed: Exceptional Quality Earns International Trust

During the technical exchange session, the clients shared actual data from using our drive axle products. Reportedly, motor graders equipped with our drive axles have performed excellently in infrastructure construction projects around Minsk, Belarus, achieving zero failures in core drive axle components over 2,000 cumulative working hours and an operational availability rate of over 98%. Particularly in extremely cold conditions, the specially optimized sealing system and low-temperature gear oil ensured normal startup and stable operation in environments as low as -35°C.

"The durability of these drive axles is impressive," said the Belarusian client representative during the exchange meeting. "In our most demanding marshland construction sites, the product's mobility and reliability completely exceeded expectations. This is a key reason for our revisit and desire to expand cooperation."

Our production and manufacturing system integrates intelligent and lean concepts. In the machining workshop, high-precision robots and machining centers from Germany and Japan process critical drive axle components; in the automated welding section, robotic welding systems ensure every weld meets the highest standards; on the assembly line, technicians use advanced torque control systems to guarantee precise and controllable fastening torque for every bolt. These advanced manufacturing equipment and processes ensure that every drive axle product delivers outstanding performance and reliability.

The company's inspection system is particularly noteworthy. Beyond routine dimensional, hardness, and cleanliness checks, each drive axle undergoes multiple testing procedures including no-load run-in tests, load tests, and sealing tests, providing comprehensive performance verification. This strict quality assurance system ensures the superior quality of products leaving the factory.

Product Advantages: Technological Innovation Drives Excellent Performance

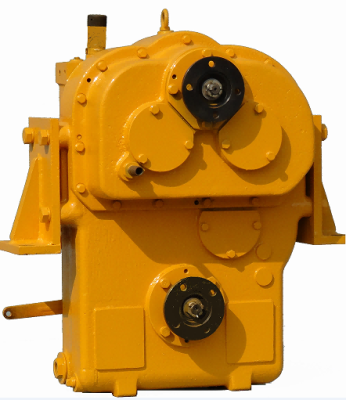

The grader drive axle we provided for the Belarusian client is an upgraded product specifically developed for the climate and working conditions of Eastern Europe. This series features a reinforced axle housing design, increasing torsional stiffness by 25% to effectively handle impact loads from uneven terrain; the optimized gear transmission system achieves over 90% transmission efficiency; the equipped wet disc brake system offers high braking torque and excellent anti-fade performance, making it particularly suitable for long-distance grading operations. These technical advantages enable graders equipped with our drive axles to excel in various infrastructure projects in Belarus.

Regarding the loader drive axle, the company made several improvements based on local usage characteristics. Specifically optimized for Belarus's cold winter conditions, the lubrication channels and sealing system ensure normal startup and operation even at -35°C. Furthermore, enhanced dust seal design for the local mining environment effectively extends maintenance intervals. Client feedback indicates that loaders using our drive axles have a failure rate more than 30% lower than comparable products under similar conditions.

Building on the successful preliminary cooperation experience, the Belarusian clients clearly expressed their desire to expand the scope of cooperation during this visit, specifically indicating interest in introducing our wheeled excavator drive axle products. During the technical exchange, engineers from both sides held in-depth discussions on the technical parameters, performance requirements, and adaptability to local specific conditions for the wheeled excavator drive axle.

The wheeled excavator drive axle series is also one of our company's competitive products. This series covers wheeled excavators from 8 to 15 tons, offering multiple configurations for customer choice. The latest models in this series adopt a modular design for strong compatibility and flexible adaptation, capable of matching different OEMs' host machines and meeting diverse application needs. They also incorporate high-end configurations such as wet disc brakes, limited-slip differentials, and differential locks, making them fully capable of handling various complex working conditions. The new transmission system design, with specially designed gear tooth profiles and meshing, ensures smooth transmission and reliable power output. The innovative cooling and lubrication system guarantees reliability under continuous operation, technical advantages that make clients eagerly anticipate the new product.

Cooperation History: From Product Recognition to Strategic Partnership

The initial cooperation with the Belarusian client began five years ago. At that time, a certain brand of motor grader purchased by the client was equipped with our drive axle. During use, the equipment's outstanding performance caught the client's attention. Particularly during a winter construction project, facing the dual challenges of extreme cold and heavy-duty operation, the reliability of our drive axle left a deep impression. The client found us through the information on the equipment nameplate, initiating this international partnership.

The first direct cooperation started with a small batch of loader drive axles. The client purchased 10 units for trial. After withstanding the test of a full construction season, the product's exceptional performance won recognition from the end-user. Subsequently, the cooperation scale gradually expanded, extending from loader drive axles to grader drive axles, and from component supply to technical collaboration. As cooperation deepened, our company gradually became an important drive axle supplier for this client.

It is especially worth mentioning that during the cooperation process, our technical team visited Belarus twice for on-site technical service. They promptly provided solutions for problems encountered by the client during use and made numerous improvements and optimizations to the products based on local actual usage conditions. This customer-centric service philosophy further solidified the foundation of mutual trust.

Quality Reputation Spreads: Indirect Exports Show Results

Notably, our products enter the international market not only through direct exports but also significantly as parts of domestic OEMs' equipment indirectly exported overseas. These products have earned a good reputation internationally based on their outstanding quality performance. Last year, a Belarusian client proactively contacted our company through the information on the product nameplate, expressing interest in cooperation. Currently, the company's products have established a stable customer base in Belarus, Russia, Kazakhstan, and other countries along the "Belt and Road" route.

In recent years, more and more international clients have found the company through product nameplates. These clients initially used host equipment equipped with our drive axles and, after experiencing the products' exceptional performance, proactively sought direct cooperation. This phenomenon not only proves product reliability but also reflects the continuously growing brand influence of "Made in China" in the international market.

To better serve international clients, the company has established a multilingual official website and technical documentation system, equipped a professional international trade team, and set up after-sales service points in key markets. Simultaneously, several region-specific customized product series have been developed considering the working condition characteristics and climate of different countries. These measures have effectively enhanced the company's competitiveness in the international market.

Future Outlook: Deepening Cooperation for Mutual Value Creation

This visit by the Belarusian clients opens a new chapter in our cooperation. Beyond continuing to deepen cooperation on grader drive axles and loader drive axles, both parties also reached a consensus on cooperation regarding the wheeled excavator drive axle. The client indicated that they will conduct trial installation and verification of the new product next quarter, with plans for batch procurement if the results are satisfactory.

Meanwhile, both parties also explored potential cooperation in more product areas. The client showed strong interest in our drive axles adapted for electric engineering machinery, hoping to collaborate on this innovative product. Additionally, matters such as establishing a regional after-sales service center and conducting personnel training were discussed. These initiatives will further enhance service quality and create greater value for the client.

The successful visit of the Belarusian clients not only consolidated the existing cooperative relationship and opened up new areas of collaboration but also demonstrated the capability and standards of Chinese drive axle manufacturing enterprises. As international cooperation advances further, the company will continue to adhere to the philosophy of "Innovation, Quality, Service," providing global customers with better products and services, and helping "Made in China" shine even more brilliantly on the world stage.

Facing the new landscape of the global engineering machinery market, the company will continue to deepen its international development strategy. In the next three years, the company plans to further increase R&D investment, focusing on breakthroughs in cutting-edge technologies like intelligent drive axles and electric drive axles, while continuously improving the product matrix. Concurrently, the company will accelerate the advancement of digital factory construction, enhancing production efficiency and product consistency through the introduction of intelligent manufacturing systems.