How to Calculate Drive Axle Weight? Shandong Lutong Provides Professional Assurance

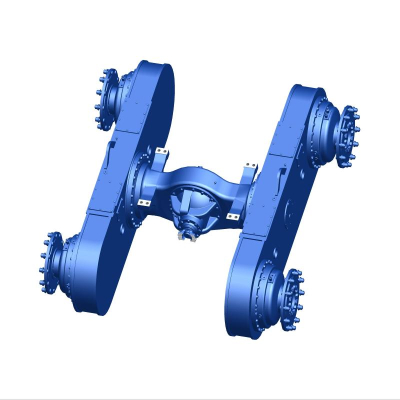

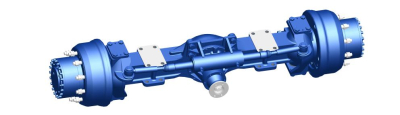

In the production and adaptation process of engineering machinery, agricultural machinery, and mining machinery, drive axle weight is far from a simple "weighing data." It directly relates to equipment operational stability (such as the center of gravity balance during wheeled excavator steering), fuel economy (energy consumption control during loader heavy-duty operation), and long-term maintenance costs. Shandong Lutong, as a professional manufacturer with over 30 years of deep experience in the drive axle field, can not only help you master scientific calculation methods but also translate "accurate calculation" into "reliable products" through full-chain technical and production strength. This is especially true for core categories like the loader drive axle, engineering machinery drive axle, and wheeled excavator drive axle assembly, where we have established a complete service system from calculation to delivery.

3 Core Steps for Drive Axle Weight Calculation: Shandong Lutong Simplifies Complex Processes

A drive axle structure includes the axle housing, transmission system, bearing assembly, and other components. Calculation requires balancing "data accuracy" and "scenario adaptation," but without complex formula overload. Shandong Lutong breaks down the process into 3 easy-to-follow steps based on accumulated experience, also providing exclusive data and technical support:

Step 1: Accurately Collect Basic Parameters – Shandong Lutong Provides a "Ready-made Database"

The prerequisite for calculation is obtaining two types of key data; missing any item can lead to result deviation.

Equipment-side Parameters: Clarify the host equipment's full-load mass, axle load distribution ratio (e.g., front and rear axle load distribution for loaders), maximum operating grade, and tire rolling radius. These data determine the drive axle's load-bearing requirements, thereby influencing structural design and weight.Drive Axle-side Parameters: Include axle housing material (cast iron or alloy steel, where density difference directly affects weight), main reducer ratio, differential gear module, half-shaft diameter, and other core structural parameters.You don't need to collect this from scratch. Shandong Lutong has established a "Drive Axle Parameter Database" covering over 120 machine models, including adaptation parameters for mainstream loader drive axles and wheeled excavator drive axles. For instance, the standard axle housing thickness for a certain 5-ton loader drive axle, or the transmission system dimensions for a specific wheeled excavator drive axle, all stem from years of cooperation with OEMs. Simply provide the equipment model, and we can quickly match the basic data, saving over 30% of parameter collection time.

Step 2: Disassemble Components for Itemized Calculation – Shandong Lutong Controls "Error" with Technology

The drive axle weight is the sum of the weights of its core components, requiring calculation based on a "disassemble - calculate - accumulate" logic. Shandong Lutong uses professional tools to ensure accuracy at every step:

Axle Housing Weight: As the "load-bearing skeleton" of the drive axle, its weight calculation centers on "volume × material density." For example, the cast iron axle housing commonly used in engineering machinery drive axles has a density of approximately 7.8 g/cm³. We use SolidWorks 3D modeling software to accurately calculate the solid volume of the axle housing (excluding internal cavities), combined with the wall thickness deviation in actual machining (error controlled within ±0.5mm), to derive the final weight. Given that loader drive axles need to withstand severe impact, the axle housing adopts a thickened design. The calculation will additionally mark the "weight increment from the reinforced structure" to avoid load mismatch during later adaptation.

Transmission System Weight: Covers the main reducer (including the drive pinion and ring gear), differential (planetary gears and side gears), half-shafts, and other components. Main reducer weight can be estimated using empirical formulas like "gear tooth number × module × material density." Shandong Lutong engineers also adjust coefficients based on actual working conditions – for instance, as wheeled excavator drive axles require frequent steering, the differential may include wear-resistant structures, and this extra weight is incorporated into the calculation.

Auxiliary Component Weight: Includes bearings (refer to standard weight manuals by model, e.g., a specific tapered roller bearing weighs about 1.2 kg), oil seals, bolts, lubricant filler ports, etc. The total weight of such components typically accounts for 8%-12% of the complete axle. Shandong Lutong calculates based on the average weight from batch production, ensuring consistency with the weight after actual assembly.

Throughout the calculation process, we use 3D scanners for "physical dimension verification" of components, controlling the calculation error within ±2% – a precision level difficult for ordinary manufacturers to achieve, and a key reason for the better adaptability of Shandong Lutong drive axles.

Step 3: Dynamic Verification Based on Working Conditions – Shandong Lutong Ensures Accuracy through "Test Validation"

After calculating the basic weight, correction based on the equipment's actual operating scenario is necessary to avoid "armchair strategy." Shandong Lutong ensures practical application through dual verification:

Condition-based Correction

Test Validation

Shandong Lutong: Not Just "Can Calculate," But Also "Can Build Well" – Full-Process Quality Assurance

For customers, "accurate calculation" is the premise, but "good performance in use" is the goal. Shandong Lutong has built a complete assurance system from technical team and production equipment to quality inspection and delivery, ensuring every drive axle (whether a loader drive axle or a wheeled excavator drive axle assembly) achieves "calculated weight = actual weight = adapted weight":

Professional Technical Team: The Foundation for Calculation and Design

The company has formed an R&D team of over 30 people, 15 of whom have more than 10 years of drive axle design experience.

For loader drive axles, the team optimized the "weight balance algorithm for heavy-duty scenarios," ensuring the axle housing weight matches the load capacity, avoiding "excessive weight increasing energy consumption" or "insufficient weight affecting strength."

For wheeled excavator drive axle assemblies, a "lightweight design model" was developed, controlling weight within a reasonable range while ensuring steering flexibility, reducing equipment fuel consumption during operation.

Regardless of the drive axle type you need to calculate, the team can provide "one-on-one" parameter interpretation and calculation guidance, even adjusting the calculation model based on your customization needs.

Advanced Production Equipment: Translating "Calculation Precision" into "Manufacturing Precision"

The best calculation results require precision equipment for realization. Shandong Lutong's production base is equipped with multiple sets of high-precision machining equipment, covering the production of all drive axle components:

CNC Gear Hobbing Machines: When machining main reducer gears, the tooth profile accuracy error is ≤0.01mm, ensuring the gear weight matches the design value and avoiding weight fluctuations due to tooth profile deviations.Coordinate Measuring Machines (CMMs): As core inspection equipment, they perform full-dimensional scanning of key components like axle housings and gears, accurately capturing details like wall thickness and pitch, ensuring component volume completely matches the design value, eliminating weight errors from dimensional deviations at the source.

Multiple Automated Lines: Employ a "Distributed Weight Traceability System." Each production line synchronously records the weight data of components during the assembly process – from bearing installation to half-shaft assembly. Every weight change is uploaded to the system in real-time. If the error range is exceeded, operations halt immediately for adjustment. This not only ensures the weight accuracy of a single drive axle but also enables efficient parallel production of multiple categories (e.g., loader drive axles, wheeled excavator drive axle assemblies).

Stringent Quality Inspection System: From "Weight Qualified" to "Quality Qualified"Shandong Lutong has established a three-level inspection process for "Raw Materials - Semi-finished Products - Finished Products," checking not only weight but also performance, ensuring every drive axle meets national standards:

Raw Material Inspection: Incoming steel, gear blanks, etc., must pass material composition and density checks via spectrometers, avoiding weight deviations due to impure materials.

Semi-finished Product Inspection: For every 10 axle housings or 5 gears, 1 is sampled for "destructive weighing" – e.g., cutting the axle housing to measure the actual wall thickness, verifying consistency with the design value.

Finished Product Inspection: Besides re-checking the complete axle weight with high-precision scales, over 20 tests are completed, including a 1-million-cycle bench fatigue test (simulating 5 years of operation intensity), sealing performance test (0.8MPa pressure, no leakage), noise test (operating noise ≤85 dB). Loader drive axles additionally undergo a "heavy-duty impact test," ensuring both weight and performance are qualified.

Efficient Delivery Service: So You Can "Get the Product After Calculation"

Conventional models of loader drive axles and wheeled excavator drive axle assemblies have sufficient stock, enabling shipment within 72 hours. Customized engineering machinery drive axles (e.g., special mining models), through a "R&D - Production Parallel Process," have a delivery cycle 30% shorter than the industry average. Furthermore, each product comes with a "Weight Parameter Report," noting the calculated value, actual weighed value, and compatible equipment models, facilitating direct use in equipment assembly.

Choose the Right Partner to Make Drive Axle Weight Calculation "More Effortless"

For equipment manufacturers or maintenance companies, the ultimate goal of calculating drive axle weight is to find a product that is "weight-appropriate and quality-reliable." Shandong Lutong can not only help you simplify the calculation process and provide accurate data but also, with 32 years of manufacturing experience, solve the pain point of "accurate calculation but poor product." By 2025, we have served over 100 OEMs, with an annual production capacity of 50,000 units/sets. The market share for our loader drive axles and wheeled excavator drive axle assemblies consistently ranks among the industry leaders.

If you are currently calculating the drive axle weight for a specific equipment model or need to procure highly adaptable engineering machinery drive axles, Shandong Lutong can provide a one-stop service of "Parameter Matching - Weight Calculation - Product Customization - After-sales Guidance," saving you from bouncing back and forth between "calculating data" and "finding products."