What You Didn't Know About Drive Axles: The Differential – The Unsung Hero Behind Efficient Construction Machinery

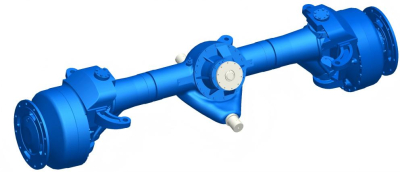

In the field of construction machinery, the drive axle, as a core transmission component, directly impacts the equipment's power performance, reliability, and service life. However, many users are unfamiliar with its working principles and technical details. Today, we will unveil the "hidden functions" of drive axles and the latest industry technology trends to help you select and maintain this critical component more scientifically.

I. Core Functions

1. Allow Differential Rotation of Left/Right Drive Wheels/Axles: This is the fundamental function of the differential. When construction machinery turns, the inner wheel travels a shorter distance than the outer wheel. The differential automatically distributes torque, allowing the inner wheel to rotate slower and the outer wheel to rotate faster. This prevents tire slippage, excessive wear, and undue stress on the drivetrain, enabling smooth turning.

2. Transmit Engine Torque: The differential transfers power received from the transmission or transfer case to the left and right axle shafts, driving the wheels forward or backward.

3. (Special Types) Limit or Lock Wheel Differential: Building upon the standard open differential, construction machinery often employs various limited-slip or locking differentials to handle challenging terrains (such as mud, snow/ice, soft ground, rough surfaces). These prevent complete loss of traction if one wheel spins, ensuring sufficient pulling force for escape or continued operation.

Note: Multiple models of Shandong Lutong's product line offer optional No-spin limited-slip differentials, such as telehandler

axle, harvester-skidder axle, etc

II. Selection Considerations

1. Machine Type & Tonnage: Small equipment might use open or limited-slip differentials; medium/large equipment commonly uses positively locking types.

2. Typical Operating Conditions: Machines primarily operating on good surfaces (e.g., some forklifts, small excavators) may use open differentials. Machines frequently operating on poor, soft, or uneven traction surfaces (e.g., loaders, bulldozers, mining trucks) must be equipped with locking functionality (positively locking or high bias-ratio limited-slip).

3. Cost & Maintenance: Positively locking differentials are relatively simple, reliable, and have lower maintenance costs, making them the mainstream choice.

4. Operational Requirements: Automatic locking simplifies operation but increases cost.

III. Common Failures

1. Differential Noise: Gear wear/pitting/tooth breakage, bearing failure, worn/loose pinion shaft, improper assembly clearance.

2. Oil Leaks: Aging/damaged seals, housing cracks, failed gaskets at mating surfaces.

3. Differential Lock Failure: Damage/jamming of locking mechanism (shift fork, sliding collar, cylinder/solenoid valve), control circuit fault (electrical/pneumatic).

4. Limited-Slip Function Failure (LSD): Excessive friction plate wear/burnout, spring failure, incorrect oil type (affects friction characteristics).

5. Overheating: Low oil level, degraded oil, overload operation, excessive internal friction due to faults.

IV. Maintenance Key Points

1. Correct Use of Differential Lock: Positively locking differentials must be operated strictly according to procedure! Use ONLY when maximum traction is needed during low-speed, straight-line travel. Unlock IMMEDIATELY after escaping the situation or when transitioning to good surfaces. NEVER turn while locked!

2. Regular Replacement of Dedicated Gear Oil: Use heavy-duty gear oil conforming to the manufacturer's specified grade and viscosity (typically GL-5 level or higher), strictly adhering to the replacement interval. Oil degradation severely impacts lubrication, heat dissipation, and friction plate performance (for LSDs).

3. Check Oil Level & Condition: Regularly check the differential oil level. Inspect drained oil for metal particles, emulsification (water ingress), or severe degradation.

4. Monitor Sealing Integrity: Inspect axle shaft seals, differential housing mating surfaces, etc., for oil seepage/leakage to prevent ingress of dust and moisture.

5. Be Alert to Abnormal Noises: Differential malfunctions (e.g., gear wear, bearing failure) are often accompanied by unusual noises (whining, knocking, clunking), requiring prompt inspection and repair.

Technological evolution in drive axles is propelling construction machinery towards greater efficiency and intelligence. As a drive axle manufacturer with 32 years of R&D experience, Shandong Lutong is committed to providing customers with customized solutions. Visit our official website or contact our engineering team for specialized technical consultation!