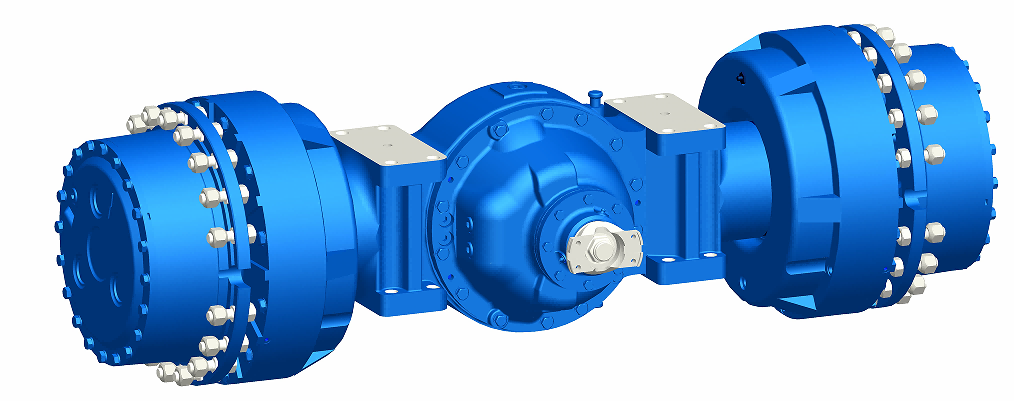

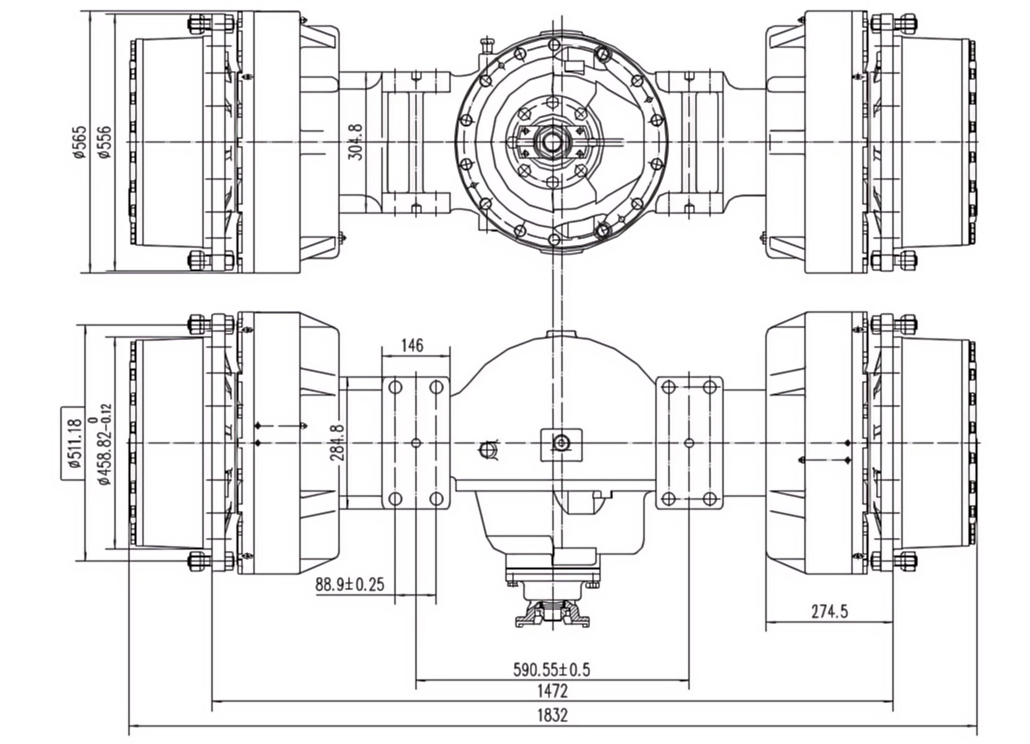

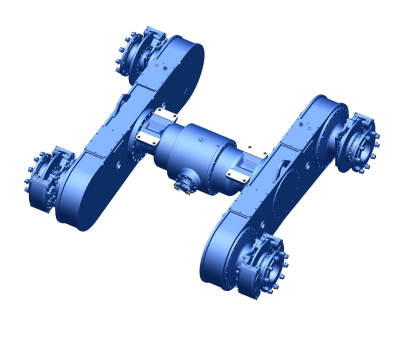

Drive Axle of Underground Scraper

1.Superior anti-slip performance with excellent traction on muddy terrain.

2.Safe and reliable braking system.

3.Exceptional sealing performance.

4.Critical components sourced from global top-tier suppliers.

5.Fast delivery cycles.

Introduction:

The drive axle of the underground scraper, designed for underground scrapers , features an ultra-large reduction ratio of 26.118 to deliver robust power support. Its monolithic cast steel housing enhances structural strength and stability. For underground safety, the integrated service and parking braking system operates via hydraulic release with spring engagement, enabling automatic braking during hydraulic failure to prevent hazards such as rollaways.

The front axle in this series utilizes a limited-slip differential that ensures maximum traction on muddy terrain. This heavy-duty axle is engineered for heavy-load applications, meeting the load requirements of large-tonnage vehicles, making it suitable for various underground mining equipment. Additionally, it offers multiple adaptation options for different vehicle models and working conditions: various reduction ratios, flange options, multiple axle lengths and diverse mounting configurations.

Main technical parameters:

Total transmission Ratio | 26.118 |

Maximum input torque | 4290N.m |

Theory maximum load | 19050Kg |

Brake structure | Spring brake/hydraulic pine brake |

Starting oil pressure of stopping braking | 10.4MPa |

Single braking capacity | 163.9ml |

Single braking moment | 20000N.m |

Brake cooling 0il and Remove tho brake oil | hydraulic oil |

0il request for driving axle(API standard) | GL-5:85W/90 Gear 0il(above-12℃) |

Company service system

Shandong Lutong Machinery Co., Ltd. provides comprehensive technical support throughout the entire product lifecycle, including preliminary development consultations, mid-cycle product optimization, and post-installation testing and field training. This holistic support system ensures customers maximize the efficiency and convenience of drive axles during operation, resolving operational challenges while enhancing the overall user experience.Upon receiving customer requirements, our engineers promptly conduct multiple feasibility validations while simultaneously initiating production line planning and developing action plans. Production and quality departments then rapidly respond to achieve efficient delivery through localized manufacturing.