Shandong Lutong’s Core Components for Harvester-Skidder and Telehandler Axles Enter Precision Machining Phase

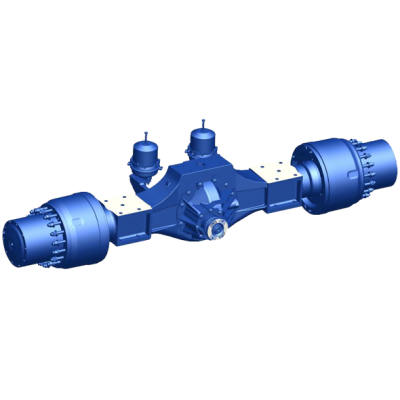

July 1, 2025 — Shandong Lutong Heavy Industries Machinery Co.,Ltd. announced today that the core components of its newly developed LTP75 harvester-skidder drive axle and telehandler drive axle have entered the precision machining stage. Engineered for specialized operating conditions with multiple innovations, these products represent a major breakthrough in the company’s specialized axle technology.

Key Technical Features of LTP75 Harvester-Skidder Drive Axle:

1. Four-stage high-reduction gear train delivers ultra-high torque, increasing driving force by 40% over conventional designs.

2. Offset power input design combined with a swing structure with slewing bearing enhances ground clearance by 50%.

3. Enclosed multi-disc wet braking system ensures braking stability.

4. Hydraulically controlled differential lock achieves response times under 0.3 seconds, providing exceptional anti-slip performance on complex terrain.

Technical Advancements in Telehandler Drive Axle:

1. Two-stage reduction design offers multiple ratio options, improving transmission efficiency by 15%.

2. Integrated service/parking wet brake system increases braking torque by 20%.

3. Integrated swing frame design lowers vehicle center of gravity by 15% and boosts installation efficiency by 40%.

4. Intelligent differential system (limited-slip differential + positive locking differential) enhances complex terrain maneuverability by 35%.

The first batch of prototypes is undergoing precision machining in the company’s digital workshop, utilizing automated machining centers to guarantee critical component accuracy. The production department has implemented enhanced quality control measures:

1. Full-process traceability system

2. 100% online inspection of critical dimensions

3. Material metallographic analysis

4. Gear meshing accuracy verification

A three-month program of bench testing and real-world operational validation will follow to ensure products meet design specifications. Key customers will subsequently be invited for on-site trial evaluations. Shandong Lutong remains committed to R&D investment to deliver more professional and reliable drive solutions for global construction machinery users.

| |