Smart Machining Lines Power Manufacturing Upgrade: Shandong Lutong Builds Quality Foundation with Global Equipment

In modern construction machinery manufacturing, smart machining lines have become a critical factor determining core competitiveness. They serve not only as the core engine for production efficiency but also as vital support for ensuring product precision and consistency—directly impacting component performance stability and service life. This plays an irreplaceable role in market expansion and brand reputation building.

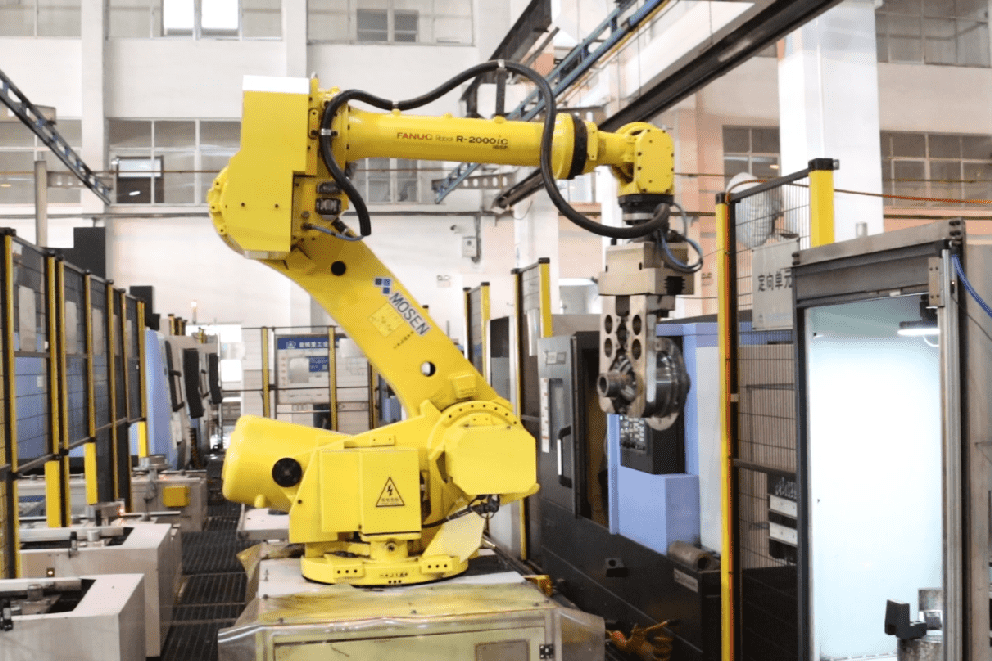

Shandong Lutong Heavy Machinery Co., Ltd. understands the core value of smart manufacturing and has established advanced smart machining lines as a cornerstone of its development. Utilizing an automated production system comprising robotic arms from international leaders like ABB, FANUC, and KUKA integrated with high-precision machine tools, combined with real-time monitoring and data analytics capabilities of smart production management systems, the company achieves high-precision and efficient manufacturing of core construction machinery components. Through full-process quality control, it ensures product consistency and stability, setting a benchmark for quality.

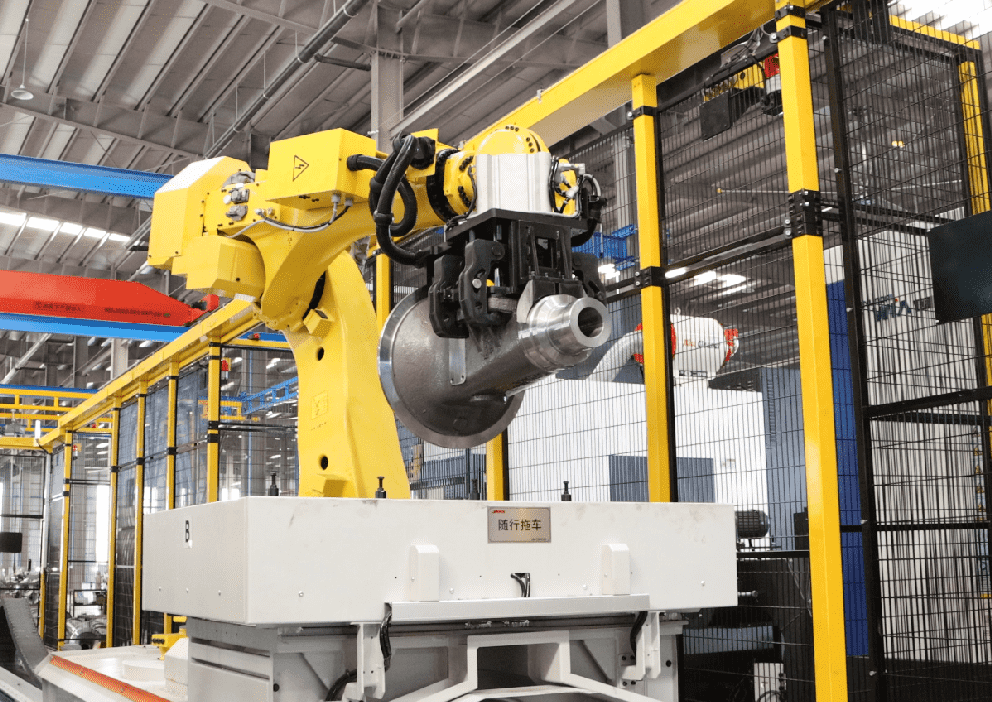

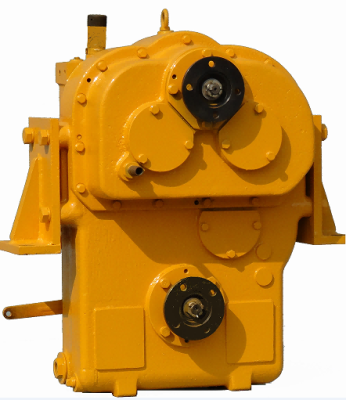

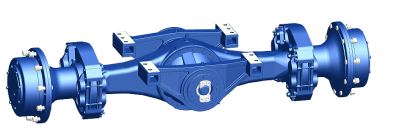

Shandong Lutong's smart machining lines comprehensively cover:Axle housing smart machining lines、Axle arm smart machining lines、Planetary carrier smart machining lines、Main reducer housing smart machining lines、Differential housing smart machining lines and Smart welding lines.These precisely address the machining and forming needs of key engineering machinery components.

On the axle housing smart machining line, KUKA robotic arms handle precise transfer and positioning of parts, while high-precision CNC machine tools complete key processes such as drilling and boring. The smart production management system collects core parameters like cutting force, spindle speed, and feed rate in real time. Upon detecting minor fluctuations, it automatically issues alerts and dynamically adjusts machine parameters to prevent error accumulation. This model maintains machining accuracy within micrometer-level tolerances, fundamentally ensuring the structural stability of axle housings as core load-bearing components. It reduces dimensional deviation rates by over 90% compared to traditional production methods.

The axle arm smart machining line employs FANUC robotic arms. Addressing the complex curved surfaces and multi-station machining characteristics of axle arms, the robotic arms efficiently handle part transfer and positioning between different machine tools. Processes like milling and chamfering are precisely executed by dedicated machine tools. By analyzing historical machining data, the smart system automatically optimizes tool paths and cutting parameters, ensuring highly consistent machining trajectories across different production batches. Compared to manual operations, this automated approach not only significantly boosts efficiency but also completely avoids errors from manual handling and positioning, substantially improving dimensional accuracy and surface finish. Dimensional consistency within the same batch is controlled within 0.02mm.

As critical transmission system components, planetary carriers demand extreme machining precision. Shandong Lutong's planetary carrier smart machining line uses ABB robotic arms for entire-process transfer and positioning, ensuring precise and controllable material flow from raw material loading to finished product inspection. Core machining processes are handled by high-precision dedicated machine tools. The smart production management system integrates data from coordinate measuring machines, performing real-time checks on the coaxiality of gear mounting holes. If trends exceeding standards are detected, it immediately provides feedback to machine tools for parameter correction. The robotic arms' exceptional repeatable positioning accuracy, combined with the system's dynamic calibration capability, stabilizes coaxiality errors within 0.01mm, laying a solid foundation for smooth transmission system operation.

The main reducer housing and differential housing smart machining lines also follow the collaborative model of robotic transfer and positioning combined with machine tool precision machining and system monitoring. In main reducer housing machining, robotic arms precisely deliver parts to machining stations. CNC machine tools process key areas like bearing bores and threaded holes. The system collects data such as cutting temperature and vibration frequency in real time, uses algorithmic models to predict tool wear, and prompts tool changes in advance to prevent defects. The differential housing line incorporates FANUC robotic arms. Through high-speed, stable transfer and positioning coordinated with dedicated machine tools, the smart system establishes a full-batch quality database. By comparing and analyzing machining data from different periods, it identifies minor quality fluctuation trends and automatically optimizes process parameters, ensuring high consistency in every housing produced. The product pass rate remains consistently above 99.5%, fully complying with stringent quality standards.

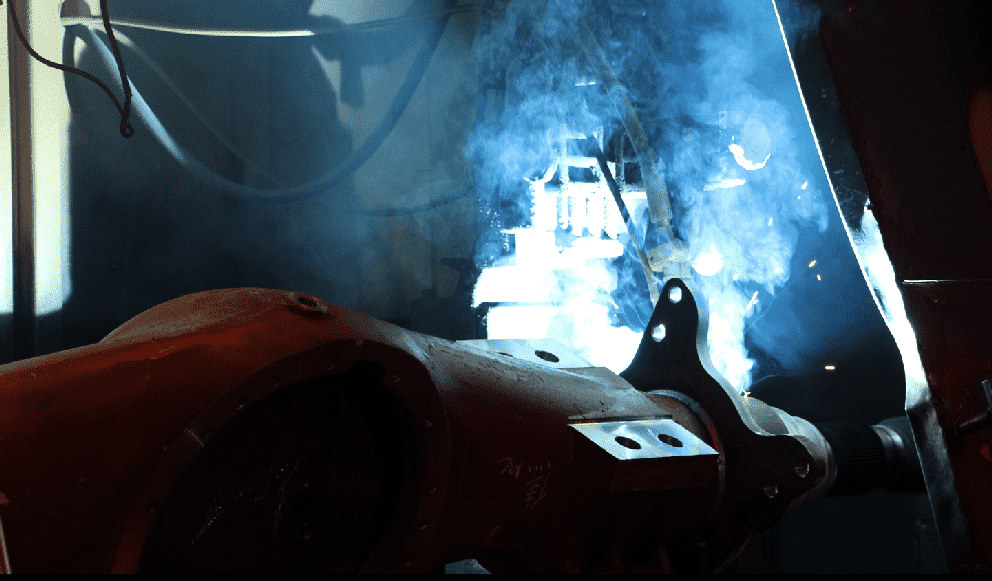

Shandong Lutong also operates smart welding lines where robots handle weld seam positioning and welding operations. The smart system monitors key parameters like welding current, voltage, and molten pool temperature in real time. Using vision recognition technology, it inspects weld seam formation and immediately pauses operations and issues alerts upon detecting potential issues like false welding or missed welding. The system also records process data for each weld, creating traceable quality files that provide data support for subsequent process optimization. This has increased weld strength compliance rate to 99.8%, effectively ensuring structural integrity and durability of components.

Shandong Lutong has always regarded product quality as its lifeline. The smart machining lines, composed of robotic arms from international leaders integrated with high-precision machine tools, coupled with the real-time monitoring and data analytics capabilities of the smart production management system, collectively form a full-process quality control system. Automated production reduces human factor interference by over 70%. The precise transfer and positioning by robotic arms provide a stable benchmark for machine tool machining. Real-time system monitoring allows for prompt identification and resolution of potential issues. Full digital traceability ensures every step from raw material input to finished product delivery is documented, enabling continuous process optimization through data review and driving continuous quality improvement.

This first-class product quality has gained widespread market recognition—leading domestic OEMs like SANY, Shantui, and Lovol have established stable cooperative relationships with Shandong Lutong. In the Russian market, the company has also successfully partnered with renowned OEMs like PTZ and UMG. These enterprises have extremely stringent standards for component quality. The core reason for choosing Shandong Lutong is the exceptional performance of its products in precision, stability, and durability.

Leveraging advanced automated lines and reliable product quality, Shandong Lutong continues to demonstrate its manufacturing strength to the global market. In the future, the company will deepen the integrated application of smart production lines and management systems, further enhance international product competitiveness, and provide global customers with high-quality core components for construction machinery.