Rigorous Bench Testing Validates Exceptional Performance: Shandong Lutong Heavy Industry's Steering Drive Axle Leads Telescopic Handler Technology Innovation

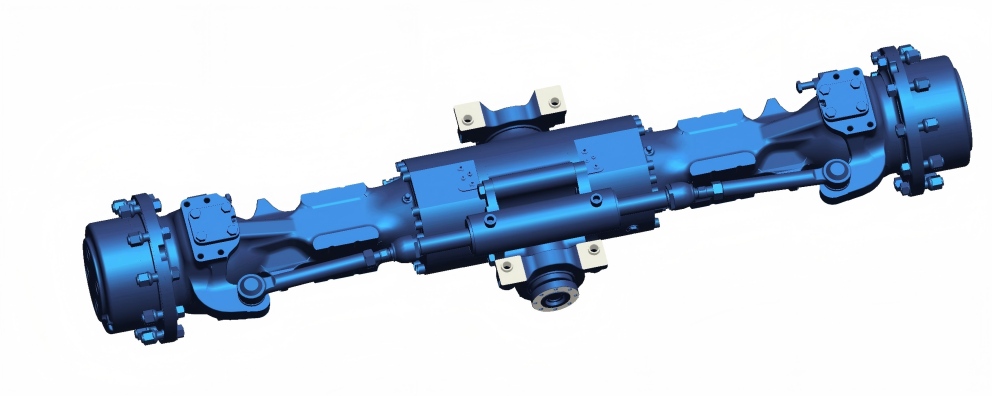

Amid the operation of a national authoritative laboratory, the newly developed modular steering drive axle from Shandong Lutong Heavy Machinery Co., Ltd. is undergoing comprehensive systematic bench testing. This innovative product demonstrates the power of Chinese intelligent manufacturing through its exceptional performance. Designed as a core component for telescopic handlers, this drive axle redefines the technical standards for off-road vehicle drive systems with its highly modular design, bringing revolutionary changes to the entire industry.

Drive Axle Bench Testing: Verifying Reliability with Extreme Standards

This systematic bench testing leverages the top-tier capabilities of the national laboratory, employing test protocols far exceeding industry standards. Our testing regimen simulates conditions harsher than real-world operating environments to validate the product's reliability and durability under the most severe circumstances. This is not merely technical validation but a fulfillment of our commitment to customers.

The Axle Housing Vertical Stiffness Test employs hydraulic servo systems to simulate extreme load scenarios, evaluating the axle's anti-deformation capability to ensure long-term structural stability.

The Axle Housing Vertical Bending Fatigue Test is even more impressive. Its million-cycle endurance testing simulates all potential impacts and jolts over the product's entire lifecycle, with loads significantly exceeding actual working conditions to assess fatigue resistance under prolonged high-frequency loading.

The Drive Axle Assembly Gear Fatigue Test validates the gear transmission system's ability to maintain stable output under high-torque, high-speed extreme conditions. Utilizing a unique stepped loading pattern that ultimately far exceeds rated torque values, this test verifies the system's robustness, reliability, and efficiency.

Modular Drive Axle Design: Redefining Industry Technical Boundaries

The innovation value of this drive axle is reflected not only in test data but also in its revolutionary design philosophy.Its inherently robust design genetics make it perfectly suited for the high-load, frequent steering operations of telescopic handlers. The product uses high-strength cast steel materials and computer-optimized structures to significantly enhance load-bearing capacity.

Modular architecture is the core innovation. This design allows quick replacement of various specifications of brake modules, differential assemblies, and wheel-end reduction mechanisms. It not only meets mainstream OEM requirements but also adapts flexibly to over ten types of special equipment including wheeled excavators, backhoe loaders, and aerial work platforms. This modular platform satisfies diverse needs, eliminating the requirement for customers to stock multiple spare parts for different equipment, reducing procurement and storage costs by over 30%.

Reliability principles permeate the entire process from design and material selection to manufacturing and testing. We consistently adhere to the highest standards, aiming to become the most reliable power transmission core for your equipment.

Craftsmanship Manufacturing: Three Decades of Focus Achieving Excellence

As an enterprise with over 30 years of specialization in drive axle R&D and manufacturing, Shandong Lutong Heavy Machinery consistently promotes industry advancement through technological innovation. The company is certified as a high-tech enterprise and holds over 70 national patents. These technological accumulations provide a solid foundation for the successful development of this product.

The company's general manager stated, "From raw material intake to finished product delivery, we implement over 100 quality inspection procedures. Each drive axle undergoes dozens of specialized tests including dimensional accuracy, hardness, and cleanliness. It is this relentless pursuit of quality that enables our products to withstand the most stringent tests."

The intelligent production lines introduced at the manufacturing base are key to quality assurance. Automated machining centers achieve micron-level precision for critical components, while robotic welding stations ensure consistent weld quality.

Testing Demonstrates Strength, Data Defines the Future

Testing is currently ongoing, and we are fully confident. The valuable data from this bench testing not only validates product reliability but also provides crucial insights for future product optimization. Temperature sensors monitor thermal distribution in real time during testing, while vibration sensors record the slightest variations, enabling deep understanding of product performance under extreme conditions.

Application Prospects: Enabling Multi-Sector Equipment Upgrades

The application potential of this rigorously tested steering drive axle is promising. In port logistics, it provides powerful performance and precise control for container handlers. In mining operations, it helps large equipment cope with challenging conditions. At construction sites, it offers reliable support for aerial work platforms.

We have established collaborations with several leading domestic OEMs, with the first batch of products destined for the newest intelligent handlers. Customers particularly appreciate our modular design, which enables them to meet diverse equipment needs with fewer spare parts. Moving forward, we will continue to share the product's performance in practical applications such as port logistics and mining operations, using indisputable test data to ensure your equipment's performance and operational safety. Let us advance together, driving the great transformation from Made in China to Innovated in China!