Powering Construction Equipment Upgrades - Shandong Lutong Steering Axles Boost Multi-Model Host Machine Performance

The performance of host machinery in the construction equipment industry is intrinsically linked to core component quality. As a specialized drive axle R&D and manufacturing enterprise, we leverage deep technical expertise, advanced production equipment, and stringent quality control to deliver high-performance steering drive axle solutions for wheeled excavators, backhoe loaders, and other host equipment. Our products successfully enhance customer equipment performance and market competitiveness. Below are detailed application cases demonstrating our axles' exceptional field performance.

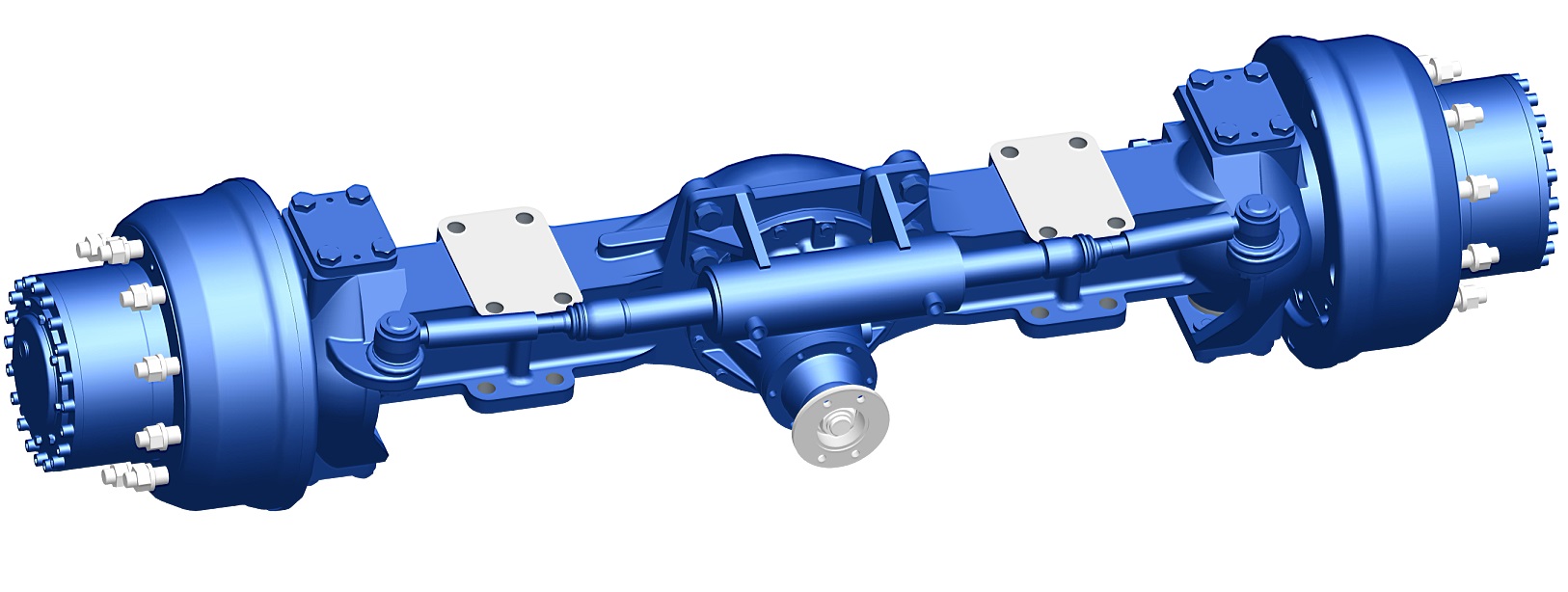

Case 1: Wheeled Excavator Steering Axle - Stable Output in Complex Conditions

A leading construction machinery manufacturer specializing in compact wheeled excavators required axles that combined exceptional maneuverability for tight spaces with robust load capacity and durability to withstand frequent impacts.

After thorough analysis of operational requirements, we recommended our 12-ton wheel excavator drive axle. This axle balances lightweight design and high strength, utilizing high-strength alloy housing with optimized structural design to enhance impact and fatigue resistance while reducing weight. Reinforced gears improve transmission efficiency and reduce power loss, while imported oil seals ensure reliable operation in muddy and aquatic environments. Precision machining ensures component assembly accuracy, minimizing wear and energy loss.

Field tests in muddy farmland and urban construction sites demonstrated exceptional steering responsiveness, improving operational efficiency in narrow spaces. After 8 hours of continuous operation, the axle temperature remained below 65°C with no lubricant degradation. Key component wear was minimal, validating the cooling and sealing systems. Customer feedback confirmed 40% lower failure rates and 25% higher operational efficiency, delivering significant economic benefits.

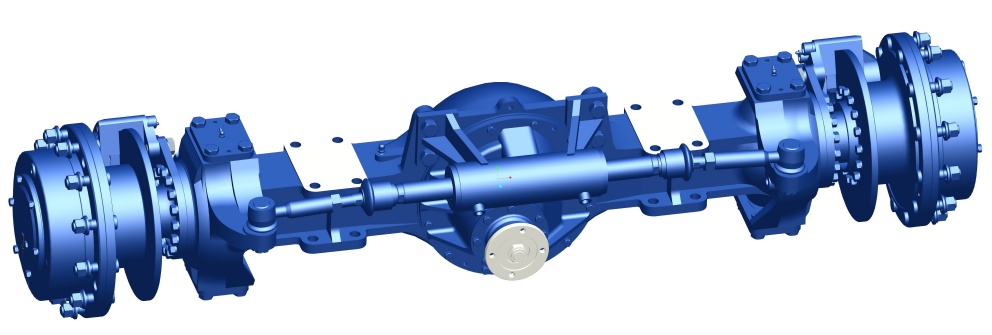

Case 2: Backhoe Loader Steering Axle - Balancing Heavy Loads and Flexibility

Backhoe loaders require axles that withstand massive longitudinal forces during digging while providing agile steering for site mobility. After rigorous testing, a customer selected our 13-ton steering axle.

This axle was designed using mechanical analysis and simulation to reinforce critical stress areas, enhancing load capacity and fatigue resistance by 20% above industry standards. Optimized gear geometry and materials improve torque capacity, while refined wheel-end reduction parameters ensure balanced load distribution and extended service life.

Production involves strict quality controls: ultrasonic cleaning, precise assembly with bearing preload and gear backlash checks, and comprehensive testing for reliability, noise, binding, overheating, and leakage. The axle passed rigorous bench testing at national laboratories before field deployment.

The customer reported international-class performance with 18% lower procurement costs, providing significant market advantages.

Robust R&D Capabilities:

Our 60+ mid-to-senior technical specialists possess deep expertise in mechanical design, materials science, and hydraulic systems. They drive structural optimization and performance enhancement for engineering machinery axles, continuously monitoring industry trends and market demands. With 10+ new patents annually, this team provides sustained momentum for product upgrades and technological advancement.

Intelligent Manufacturing System:

We have invested heavily in advanced automation including Swiss ABB robots and Japanese FANUC systems, establishing a smart production line spanning component processing to final assembly. This enables high-precision, efficient manufacturing while ensuring product consistency and quality stability. Our intelligent production management system facilitates real-time monitoring and data analytics, allowing prompt issue identification and resolution to continuously improve both efficiency and quality.

Rigorous Quality Control:

Quality is our lifeline. Every axle undergoes multiple inspection stages: raw material verification, in-process component checks, and post-assembly validation. We rigorously vet suppliers to ensure premium materials, employ advanced metrology for real-time monitoring of critical parameters like dimensional accuracy and surface finish during machining, and conduct 10+ precision tests on finished products. Only axles passing all checks reach the market.

Our steering axles are widely used in wheeled excavators and backhoe loaders, supported by an annual capacity of 50,000 units. Contact us to customize high-performance axle solutions that enhance your market competitiveness and business value. Let’s build the future of construction machinery together!