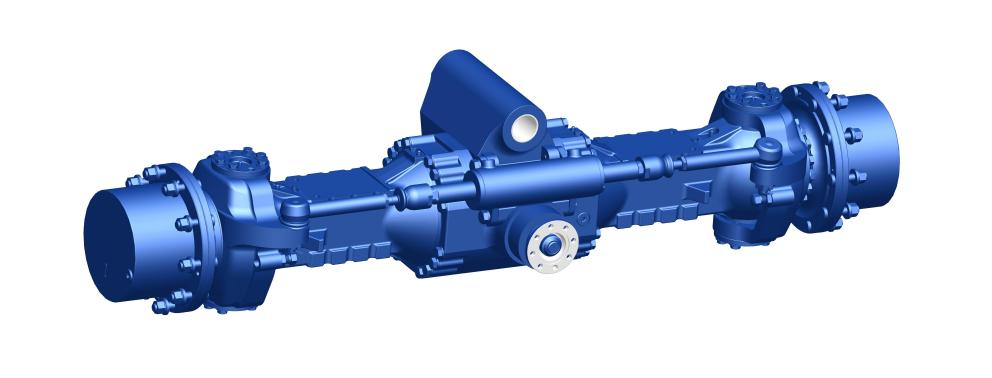

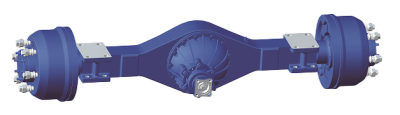

15 Ton Wheel Excavator Drive Axle

1. Multiple transmission ratios can be selected

2. Multi-disk wet braking

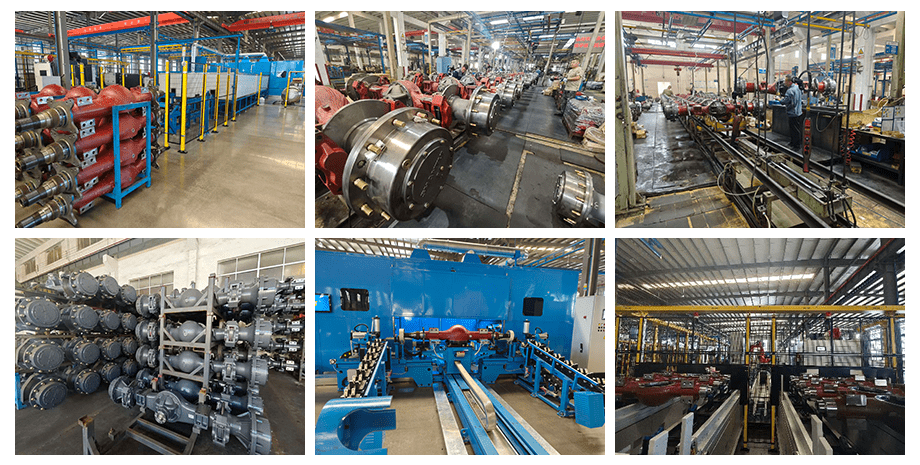

3. Large-scale production capacity

4. Mature production technology

5. Short delivery time

Introduction:

As the core transmission component of the wheel excavator, the 15 ton wheel excavator drive axle assumes the important responsibility of smoothly transmitting engine power to the drive wheels. It also needs to bear complex loads in the longitudinal, transverse and vertical directions generated during the excavator operation. The overall structural design needs to be fully adapted to the weight, power parameters and operating conditions of the 15 ton wheel excavator to ensure that stable power output and flexible driving control can be achieved in various operating scenarios such as municipal engineering, road construction, farmland transformation, and small mines.

From the perspective of component composition, this type of drive axle usually includes key components such as main reducer, differential, half shaft, wheel hub, brake system and housing. The main reducer adopts internationally leading bevel gear technology, and the transmission efficiency is increased to more than 95%. The noise is significantly reduced compared with traditional spur bevel gears, and it can still maintain stable operation under heavy load conditions. The dynamic load-bearing capacity reaches 13,000kg, and the multi-disc wet braking emergency braking is more reliable. The 15 ton wheel excavator drive axle developed by Shandong Lutong has supplied to many domestic and foreign OEM factories, and has achieved long-term cooperation with many domestic and foreign OEM factories, including SANY, Shantui, Lovol, Liugong, UMG, PTZ, etc.

Key performance parameters of the product and operation adaptability

The performance parameters of the 15 ton wheel excavator drive axle are designed around the three core requirements of "heavy-load adaptation, efficient transmission, and wide-domain adaptation". The specific parameters and operating value correspond to the following:

Power transmission parameters: The transmission ratio can be selected from 14-22, the maximum output speed is 50,000N.m, and can match the engine commonly used by 15-ton wheeled excavators. It has high transmission efficiency. Compared with traditional drive axles, it can reduce power loss and improve the excavation force and driving speed during equipment operation;

Environmental adaptation parameters: working temperature range - 26℃ to 60℃, ensuring smooth start-up, reducing oil temperature, and adapting to various operating scenarios.

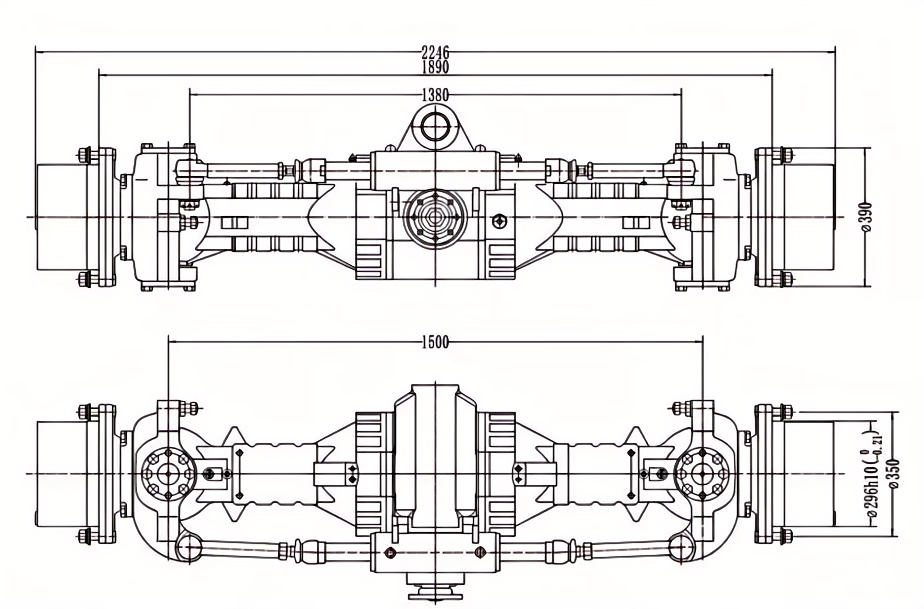

Load and driving parameters: rated load-bearing weight of a single bridge is 12-15 tons, suitable for the vehicle weight of a 15-ton wheeled excavator, meeting the weight support needs of the equipment when fully loaded. It can be adjusted according to the customer's chassis design to meet the flexible steering needs of municipal narrow sites, indoor engineering and other scenarios;

Main technical parameters:

Total transmission Ratio | 16.91 |

Maximum Output torque | 50000N.m |

Dynamic load each axle | 13000Kg |

Braking torque(single side) | 21000N.m |

Braking oil pressure | 4Mpa |

Braking displacement | 45-128ml |

Angle of turning | 32/25° |

Steering cylinder pressure | 14Mpa |

0il request for driving axle(API standard) | GL-5:85W/90 Gear 0i1(above -12 ℃) |

Brake and cylinder oil | L-HLA6 hydraulic oil |

Company product advantages

Adaptability and flexibility: In the research and development and production of 15 ton wheel excavator drive axle, the company focuses on the general adaptation characteristics of the products. The drive axles are compatible with the installation size and power interface of most mainstream brands of 15 ton wheel excavators on the market, reducing the adaptation problems caused by model differences, and providing customers with more convenient replacement and upgrade options. At the same time, personalized customized adjustment services can be provided according to customers' special operating needs, such as enhanced design for high-load operation scenarios, protection optimization for complex road conditions, etc., to meet the diversified usage needs of different customers.

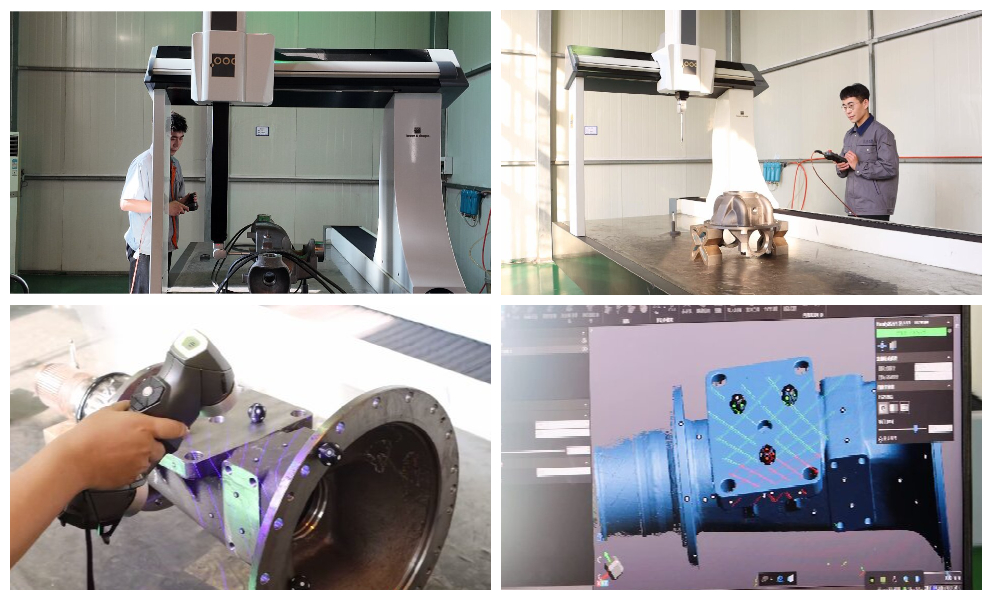

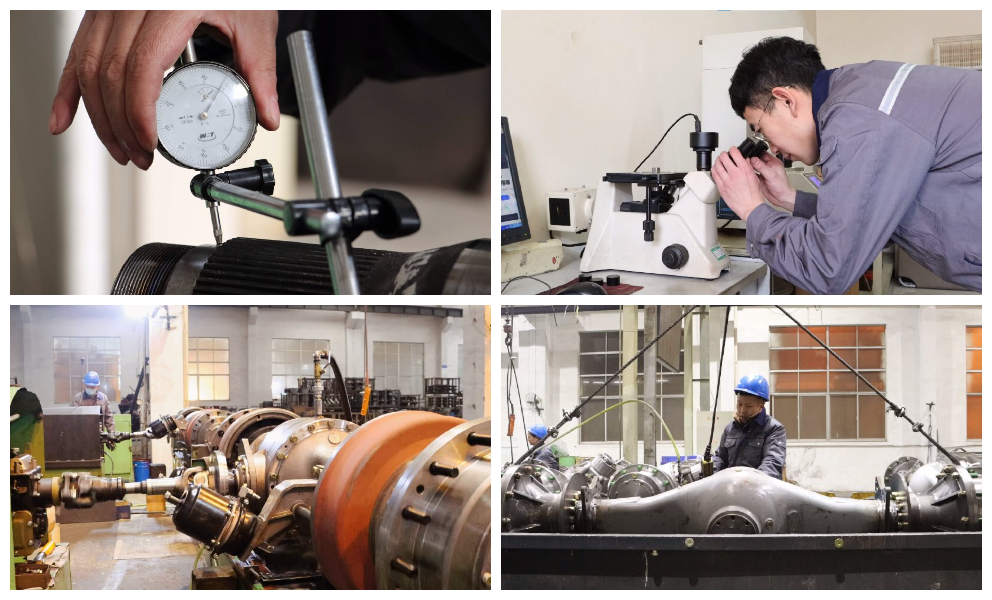

Reliable quality assurance: In the production process, the company strictly controls the procurement of raw materials, selects high-strength alloy steel, wear-resistant bearings, high-quality seals and other raw materials that meet the industry's high standards to ensure the basic quality of the drive axle from the source. During the production process, advanced processing equipment and precision testing instruments are introduced to monitor and inspect the key indicators such as gear processing accuracy, shell casting quality, and component assembly clearance of the drive axle to ensure that each factory drive axle meets the design standards and quality requirements. In addition, the company has established a complete product trial assembly and testing system, and conducted a number of rigorous tests such as bench fatigue test, sealing performance test, high and low temperature environment adaptability test, simulate the operating status under actual operating conditions, check potential problems in advance, and further ensure the reliability and durability of the product in actual use.

Efficient service system: The company has a professional technical service team to provide customers with full-process service support from product selection consultation, installation guidance to after-sales maintenance. During the product selection stage, the technicians can recommend the most suitable drive axle products to customers based on the customer's excavator model, operation scenario and other information, and provide detailed technical parameters and installation instructions; during the product installation process, if technical support is required, the service team can help customers solve installation problems through online guidance or on-site assistance; in the after-sales stage, the company has established a quick response mechanism. After the customer feedbacks the problem, the service personnel will contact and deal with it in a short time to provide troubleshooting plans and repair guidance. For situations where parts need to be replaced, ensure the timely supply of spare parts and minimize the production losses caused by equipment shutdown.

Cost and cost-effective advantages: Relying on mature production processes, large-scale production capacity and efficient supply chain management system, the company can provide customers with cost-effective 15 ton wheel excavator drive axle products with high cost performance while controlling production costs. Compared with similar products on the market, the company's products have a more reasonable price positioning while ensuring quality and performance, helping customers reduce the cost investment in equipment maintenance and upgrades. At the same time, the excellent durability of the product can effectively extend the service life of the drive axle, reduce the replacement frequency of customers, and further reduce the long-term use cost of customers.

The above, from structural design, performance adaptation to overall machine coordination, fully demonstrates the support capabilities of a 15-ton wheeled excavator drive axle for a variety of operation scenarios - whether it is stable transmission under complex operating conditions, cost optimization in long-term use, or customized adaptation in specific scenarios, all revolve around the efficient operation of the equipment and the maximization of customer value. In the future, we will continue to focus on the iteration of wheeled excavator transmission technology, optimize product details based on customer actual operation feedback, and at the same time provide a more flexible service response mechanism to provide solid guarantees for your equipment operation and maintenance and capacity improvement. If you need to know more about product adaptation solutions or obtain personalized technical consultation, please feel free to communicate with us and look forward to working with you to achieve the dual improvement of engineering operation efficiency and asset value.