Forestry Drive Axle Revolution: Powering Sustainable Logging from Core Innovation

What is Logging Equipment?

Logging equipment constitutes the core tool system for forest management, timber harvesting, and processing, encompassing the entire industrial chain from handheld chainsaws to fully automated harvesters. As global forestry shifts toward sustainable development, these machines balance production efficiency and ecological conservation through technological innovation. According to the latest market research , the global forestry equipment market is projected to grow from USD 11.33 billion in 2024 to USD 14.51 billion by 2030, at a 4% CAGR, driven by urgent demand for high-efficiency eco-friendly machinery.

Industry-Transforming Power of Forestry Equipment

Traditional logging relied on labor-intensive operations, while modern forestry equipment has fundamentally restructured the industry.

Efficiency Leap: A single harvester completes felling, delimbing, and bucking processes, replacing dozens of workers

Eco-Friendliness: Selective logging technology preserves surrounding ecosystems, reducing soil erosion and wildlife habitat disruption

Cost Optimization: Full-process mechanization lowers timber production costs by over 30% (industry data) while ensuring supply chain stability

Technological Breakthroughs in Core Equipment

Modern forestry systems feature specialized divisions:

1. Harvesting Innovations

As the pinnacle of technology, harvesters integrate intelligent measurement systems for precise diameter/length cutting, paired with high-torsion-resistance drive axles for stable operation in rugged terrain. Traditional tools like chainsaws remain irreplaceable for precision tasks.

2. Timber Extraction & Transport Upgrades

Skidders drag logs to landing areas via cables or hydraulic grapples, requiring reinforced drive axles to withstand overloaded traction. Forwarders handle short-distance transport where multi-axle drive designs and differential locks prove critical for muddy slopes.

3. Rise of Specialized Machinery

For sustainable forest management:

Mulchers achieve in-situ vegetation conversion, enhancing soil organic matter

Chippers produce standardized wood chips for biomass energy

Stump grinders with high-offset drive axles clear terrain in complex environments.

Industry Pain Points Driving Innovation

In North America (38% global share), equipment faces three core challenges:

Extreme Conditions: Unstructured terrain (mountains/swamps) increases failure rates by 40%.

Maintenance Costs: Traditional equipment downtime costs up to $5,000/day .

Customization Needs: Diverse forest environments demand scenario-specific configurations.

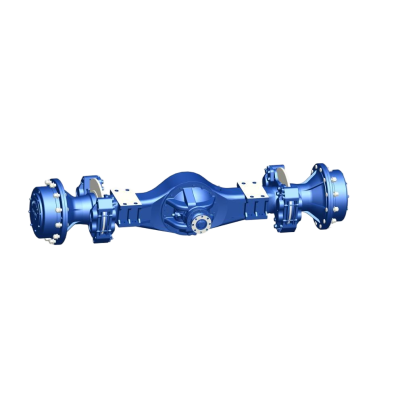

Modular Drive Axle: The Reliable Power Core of Forestry Machinery

Amid the 4% CAGR forestry equipment market, reliable, intelligent, and service-friendly drive technology has become pivotal. Addressing harsh logging environments, our modular drive axle system delivers comprehensive performance enhancements.

Featuring modular architecture, it enables rapid customization of brake systems, differential types, and connection dimensions. Configurations from Arctic sealing to tropical cooling components achieve 15-day delivery. The optimized maintenance system significantly reduces lifecycle costs—modular design streamlines disassembly/repair, cutting downtime by 70% and per-repair costs by 65%, resolving productivity loss from failures.

Terrain-specific enhancements include: High-offset design prevents collisions with stumps/rocks, improving clearance by 20%; Differential locks automatically engage on slopes to transfer power efficiently; Structural reinforcement ensures stability/safety on uneven ground. This integration of customization flexibility, serviceability, and terrain adaptability redefines value standards for forestry drive systems.

Technological Future of Sustainable Forestry

With accelerating electrification (e.g., John Deere electric harvesters) and automation (autonomous forwarders), drive systems evolve toward "electro-mechanical integration." Our modular platform features pre-installed electric drive interfaces supporting hybrid/full-electric retrofits, empowering clients to capture the 2030 $14.51 billion market opportunity.