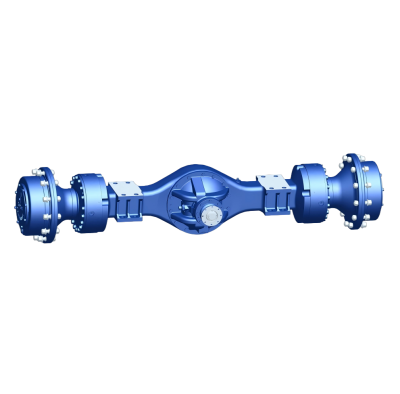

The key role of three-coordinate measuring machine in the production of drive axles and its technological innovation

In the field of driving axle manufacturing of engineering machinery, agricultural machinery and mining machinery, accuracy and reliability are the core lifeblood of products. As an industry-leading drive axle manufacturer, we always regard high-precision detection technology as an important part of quality control. With its high precision and high efficiency three-dimensional measurement capabilities, the three-coordinate measuring machine has become an indispensable quality inspection equipment on modern drive axle production lines. A three-coordinate measuring machine (CMM) is a high-precision measuring device used to detect the geometric dimensions, shapes and position tolerances of workpieces. It collects three-dimensional coordinate data of object surface points through probe contact or non-contact sensors, and combines software analysis to achieve precise measurement.

What is the working principle of the three-coordinate measuring machine?

The three-coordinate measuring machine has guide rails and sensors in three directions X, Y, and Z. Its working principle is to record the coordinates of the probe contact points through guide rails and sensors in three directions X, Y, and Z. Then the coordinate data is transferred to the corresponding computer software, which fits the multi-point data into geometric elements (such as circles, planes, cylinders) and calculates parameters such as dimensions, angles, and position degrees. Compared with traditional methods, the three-coordinate measuring machine has a high accuracy and can reach the micron level (μm). Some high-end models can even reach the nano level. Compared with traditional measurement methods, the three-coordinate measuring machine can also measure complex shapes such as some curved surfaces, gears, etc., which is of great help to improve the accuracy of the product. With the continuous improvement of the industry's requirements for driving axle accuracy, the three-coordinate measuring machine introduced by our company has been fully implemented in the mass production inspection of driving axles. The stable operation of this high-precision measurement equipment not only effectively improves the detection efficiency of key components of the drive axle, but also improves the accuracy of dimensional tolerance control, providing a solid guarantee for equipment reliability under extreme operating conditions.

How to empower the production of drive axles with a three-coordinate measuring machine?

In response to the high load requirements of excavators and loaders driving axles, the three-coordinate measuring machine can conduct tooth-shaped accuracy detection of the heat-treated gears to ensure that unqualified components do not enter the subsequent process. By scanning the three-dimensional model of the large drive axle welded parts, intelligently comparing it with the CAD design data, effectively reducing assembly problems caused by welding deformation. Combined with contactless probes, the complex curved surface of the transmission drive axle is quickly measured and the development cycle of new products is shortened.

Why choose our drive axle? ——Use detection technology to build the foundation of quality

After the introduction of the three-coordinate measuring machine, our company's drive axle production process has been further optimized. After the parts are processed, a comprehensive inspection is carried out through a three-coordinate measuring machine, which can quickly and accurately obtain the measurement data and compare and analyze it with the theoretical values of the design drawings. Once an overdue situation is found, it can be fed back to the production link in a timely manner, which will facilitate technicians to adjust processing parameters, thereby reducing waste rate, improving production efficiency and reducing production costs. At the same time, the application of the three-coordinate measuring machine also provides strong support for the company's product research and development. During the research and development of new products, it can use its high-precision measurement capabilities to conduct detailed dimensional inspection and performance evaluation, provide accurate data basis for product design improvement and optimization, accelerate the research and development cycle of new products, and enhance the market competitiveness of products.

Shandong Lutong has always adhered to the concept of "precision is life":

Full-process testing system: From the inlet of raw materials to the delivery of the finished product, the three-coordinate measuring machine participates in the quality inspection of key processes throughout the process.

International Standard Certification: The testing process complies with ISO 9001 and industry-specific standards.

Customized services: Provide targeted testing solutions according to customer machinery type.

Direction of drive axle manufacturing

The iterative upgrade of the three-coordinate measurement technology is not only an innovation in quality control methods, but also a reshaping of the core competitiveness of driving axle products. By converting measurement accuracy into product performance advantages, we are continuing to provide more reliable and efficient transmission solutions for the engineering machinery, agricultural machinery and mining machinery industries. Shandong Lutong has always been committed to providing customers with high-quality drive axle products. The introduction of three-coordinate measuring machines is another important measure for the company in quality control. In the future, the company will continue to increase its investment in technological innovation and equipment upgrades, continuously improve the intelligence and precision of drive axle production, and contribute more to the development of engineering machinery, agricultural machinery, mining machinery and other industries.