Introduction to the Composition of a Underground Scraper Axle

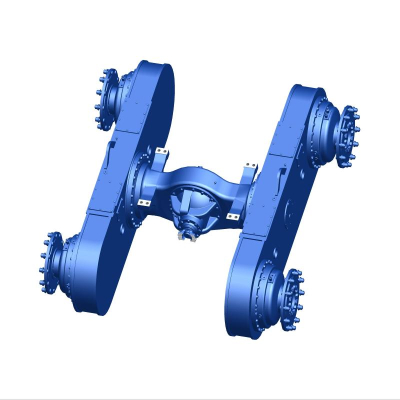

The Underground scraper machine is specialized equipment engineered for underground mining and material transport, functioning as a self-propelled unit integrating loading, hauling, and dumping operations. Within the underground LHD system, the drive axle constitutes a critical component, essential for enabling the machine's mobility, loading functions, and overall operation.

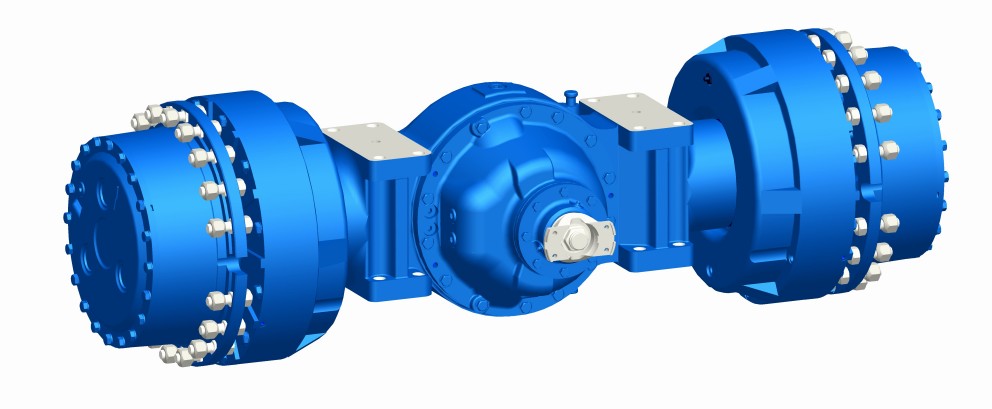

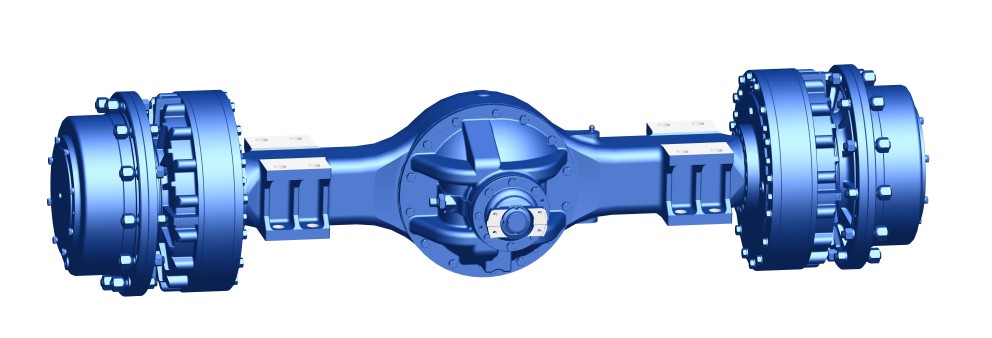

A typical drive axle assembly comprises a main reducer, differential, wheel drive assembly (final drives), and drive axle housing. Its primary functions include torque multiplication, speed reduction, and altering the direction of torque transmission. To ensure optimal performance of the underground LHD drive system, most machines utilize a drive configuration consisting of a limited-slip differential (LSD), a fully enclosed wet-type multi-disc brake, and smooth cut-resistant tires.

The adoption of a limited-slip differential (LSD) in LHD drive axles is driven by its capability to automatically distribute drive torque based on varying ground conditions. This significantly enhances machine traction, prevents wheel slippage, and reduces tire wear.

The fully enclosed wet-type multi-disc brake offers stable braking performance, high reliability, and simplified maintenance. This design effectively prevents ingress of mud, debris, and contaminants. Being a wet-type, multi-disc configuration, it features self-adjusting disc clearances and permits torque transfer during controlled slip. These characteristics make it exceptionally well-suited for demanding braking scenarios, such as descending long gradients while loaded.

Currently, the drive axles in underground LHD machines predominantly integrate the aforementioned components. This configuration demonstrably enhances the performance and reliability of the drive system while minimizing failure rates.

Shandong Lutong Heavy Industries Machinery Co., Ltd. maintains a proficient team experienced in both production and sales, specializing in the manufacturing and R&D of axles for mining machinery. Since its inception, the company has prioritized client interests, continuously assimilating design philosophies and manufacturing technologies from domestic and international peers. Core manufacturing processes have been upgraded to digitalized and CNC-processed operations. The company actively develops new products focused on cost efficiency, high productivity, and meeting specific client requirements. We welcome inquiries and collaboration opportunities.