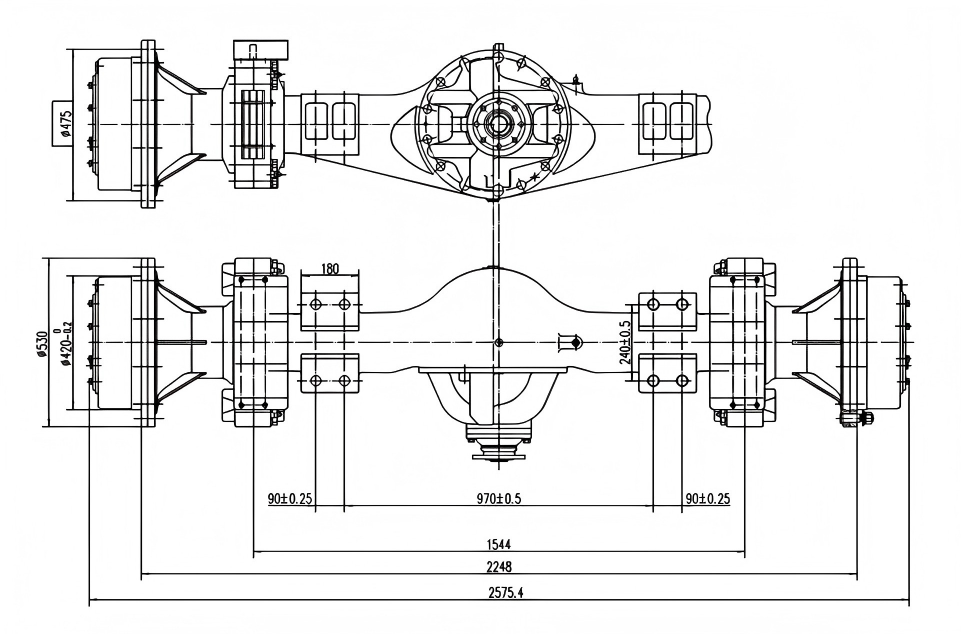

Electric Loader Drive Axle

1.High transmission efficiency, low noise.

2. Optimized compact structural design.

3. Axle housing with excellent rigidity and load capacity.

4. Large braking torque, stable and reliable performance.

5. Consistent quality reliability

Introduction:

Electric loader drive axle is specifically engineered for 5-ton electric loaders, this rigid axle features a rectangular-section housing cast from premium steel. The main reducer employs higher-strength Oerlikon spiral bevel gears to withstand increased torque input. Planetary gears at the wheel end utilize aerospace-grade materials and ground-tooth technology, ensuring stable power transmission. These material and process innovations deliver exceptional structural strength, reduced noise emissions, and enhanced operational stability, meeting stringent performance demands for heavy industrial applications.

Main technical parameters:

Total transmission Ratio | 22.853 |

Maximum input torque | 5800N.m |

Load each axle | 30000Kg |

Braking oil pressure | 11Mpa |

Braking capacity | 8.8ml |

Braking moment | 13050N.m |

Oil request for driving axle (API standard) | GL-5:85W/90 Gear Oil (above -12 ℃) |

Oil request for brake | L-HL46 Hydraulic oil |

Drive shaft assembly is shipped:

To ensure smooth shipment of electric loader drive axles, multiple measures must be implemented.First, regarding packaging: Utilize robust wooden or steel racks for comprehensive protection against impact and displacement during transit.Second, during loading/unloading: Employ specialized lifting equipment operated by trained personnel following standardized procedures to ensure stable placement on transport vehicles.

Additionally, conduct thorough inspections of transport vehicles to verify overall roadworthiness, including functional tires, brakes, and other critical components.