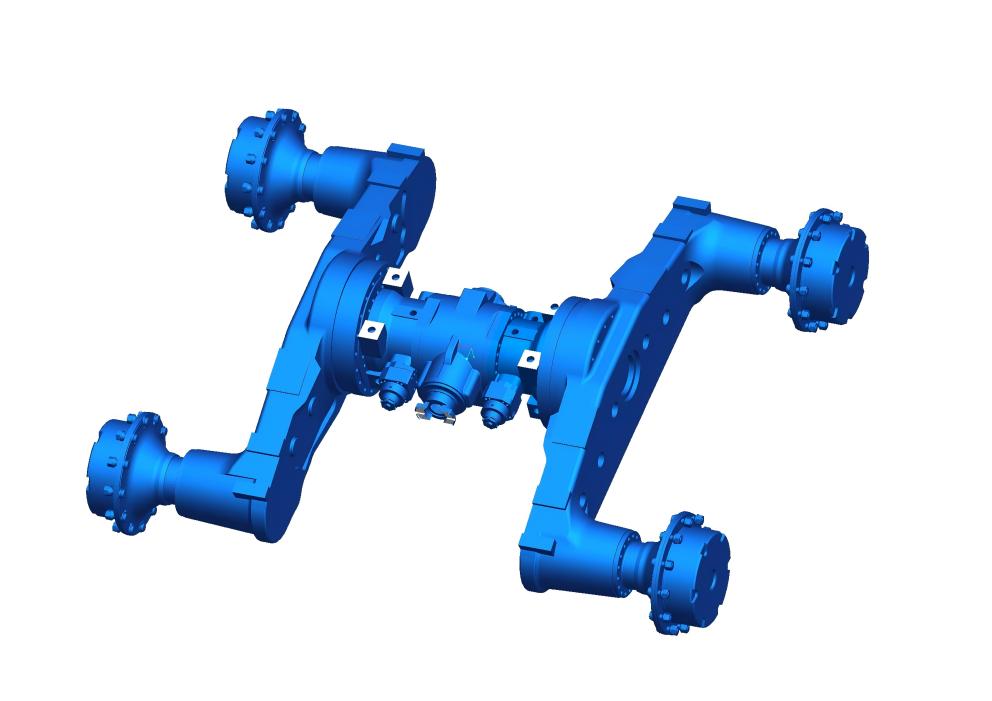

Game-Changing Forestry Off-Road Drive Axle! Shandong Lutong’s Harvester-Skidder Axle Redefines Drivetrain Technology

Shandong Lutong – a global leader in drive axle manufacturing – has launched its dedicated forestry drive axle for extreme-terrain skidders. Engineered to meet Russia’s rigorous operational demands, this solution redefines reliability and power through a four-stage reduction gear system, balanced axle transmission, and intelligent differential locking technology.

⚙️ Core Advantages: Built for Forestry & Off-Road

1️ High-Torque Output

Four-stage gear reduction delivers industry-leading drive torque (5,600 kN·m), enabling seamless operation in deep snow, marshland, and 45°+ slopes.

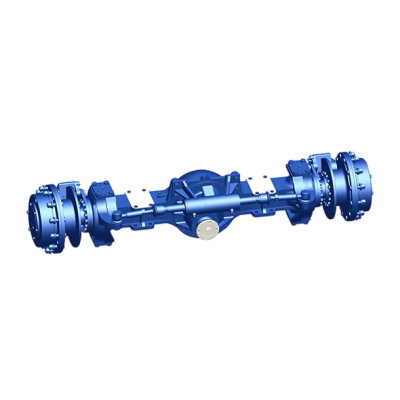

2️ Optimized Ground Clearance

Power input/tire center offset design maximizes obstacle clearance (>350 mm), conquering stumps/boulders in Russian taiga forests.

3️ Efficient Power Transfer

Multi-gear balanced axle transmission achieves 98%+ mechanical efficiency, reducing energy loss and extending service life by 30%.

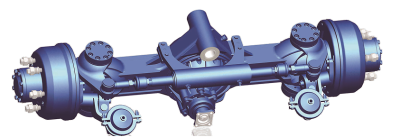

4️ Terrain-Adaptive Stability

Oscillating pivot design absorbs 50% more impact than rigid axles, lowering maintenance costs via reduced structural stress.

5️ All-Condition Traction & Safety

Sealed multi-disc wet brakes perform at -50°C; hydraulically-locked differentials ensure 100% slip control on ice/loose soil.

🌲 Key Applications

Winter timber extraction in Arctic conditions

Marshland operations (swamp mats optional)

Mountainous skidding (>30° incline)

📌 Technical Specifications

Total Reduction Ratio: 25:1

Max. Output Torque: 5,600 kN·m (customizable)

Brake Life: ≥10,000 operating hours (ISO 3450)

Swing Angle: ±12° (SAE J2195)

Prototype testing and engineering support available via official channels.