Shandong Lutong: Premium Drive Axles for the Global Market

Recently, the specialized foreign trade team of Shandong Lutong Heavy Machinery Co., Ltd., bringing core Drive Axle product technical solutions, conducted in-depth inspections and customer meetings at major industry exhibitions in Wuhan and Shanghai. This trip not only achieved upgraded cooperation with three major OEMs - Russia's Amkodor, PTZ, and Rostov - but also highlighted the overseas competitiveness of Chinese Drive Axle enterprises through the dual advantages of "Full-Chain Foreign Trade Services + Comprehensive Manufacturing Strength," pressing the "accelerator" for global market expansion.

Foreign Trade Business: Full-Chain Customized Services, Setting a Benchmark for Overseas Cooperation

As a leading domestic enterprise in Drive Axle export trade, Shandong Lutong has established a full-cycle foreign trade service system covering "Demand Liaison - Solution Customization - Logistics Delivery - After-sales Support," becoming a "Trusted Partner" for overseas clients.

Professional Team for Precise Liaison: Multiple members of the foreign trade department possess over 5 years of experience in engineering machinery foreign trade, ensuring "customer inquiries responded to within 2 hours, customized solutions provided within 3 days." Addressing pain points in technical communication with foreign clients, the team innovatively offers "Bilingual Technical Manuals + One-on-One Video Conference" services, ensuring seamless installation and commissioning of Engineering Machinery Drive Axles and Loader Drive Axles. Foreign clients remark: "Shandong Lutong's service makes us feel 'localized' professionalism."

Flexible and Efficient Demand Adaptation: For the differentiated needs of overseas clients, the team collaborates with the R&D department to establish a "Rapid Response Mechanism for Foreign Trade Orders" - conventional Drive Axle models can be adjusted for paint color and packaging specifications per customer requirements; customized Loader Drive Axles (e.g., with adjusted reduction ratios for specific tonnage loaders) take only 7 days from solution confirmation to production start.

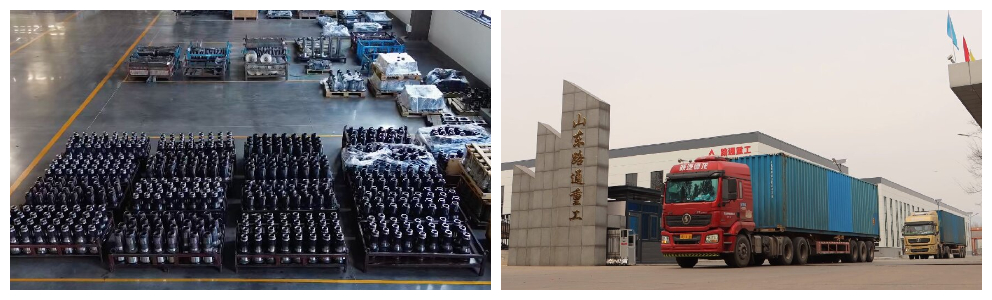

Practical Cross-Border Delivery Assurance: Long-term partnerships with multiple logistics providers optimize route planning considering Russian transportation characteristics. Conventional Drive Axles via "Sea + Land" combined transport have a stable transit time of 35-40 days; for urgent spare part requests, a "Dedicated Transport Line" is available, delivering critical spares (e.g., seals, bearings for Engineering Machinery Drive Axles) to the client's facility within 7-10 days. Additionally, a "Dedicated Foreign Trade Spare Parts Zone" in the warehouse stocks over 2,000 common Loader Drive Axle components for quick response to replenishment needs, achieving a 99% on-time delivery rate for foreign trade orders.

Impressive Foreign Trade Performance: In 2024, Drive Axle export value exceeded 120 million RMB, a year-on-year increase of 45%, with the Russian market accounting for 60%. Core clients like Amkodor and PTZ have a repurchase rate exceeding 80%. Export volume of Engineering Machinery Drive Axles consistently ranks among the top 5 domestically within the industry.

Corporate Strength: Integrated R&D + Production + QC, Fortifying the Product Foundation

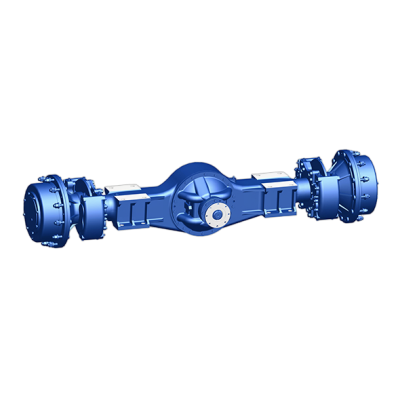

The continuous breakthroughs in foreign trade stem from Shandong Lutong's comprehensive and robust capabilities in the Drive Axle field, providing overseas markets with "High-Quality, High-Adaptability, High-Stability" product assurance.

Industry-Leading R&D Strength: The core R&D team includes multiple members with over 10 years of experience in Engineering Machinery Drive Axle design, equipped with internationally advanced tools like SolidWorks 3D design and ADAMS dynamics simulation. For Russia's extreme cold conditions, the R&D team optimized Drive Axles in just 3 months through upgraded anti-freeze lubricants and improved seal structures, achieving a zero failure rate for products supplied to Amkodor.

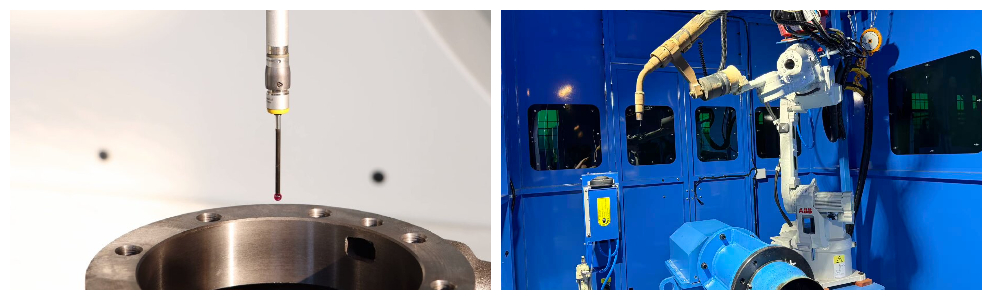

Intelligent Production Leadership: The established intelligent production base features multiple dedicated Drive Axle production lines meeting top industry standards - German KUKA robotic welding lines achieve axle housing welding precision ≤0.1mm; five-axis machining centers improve key component processing efficiency by 50%; daily capacity for conventional Drive Axles reaches 300 units, with an annual capacity of 50,000 sets. The on-time delivery rate for foreign trade orders is 100%, and customized order cycles are controlled within 35 days, 20% shorter than the industry average.

Stringent Quality Standards: A "12-Step Full-Process Quality Inspection System" is implemented, equipped with high-end devices like CMMs and scanners. Raw materials undergo dual checks for mechanical properties and chemical composition upon arrival; 100% dimensional verification is performed on core components; finished Drive Axles must pass 500-hour heavy-duty tests and air tightness tests. Exported Engineering Machinery Drive Axles for Russia undergo additional tests including -40°C cold start and salt spray corrosion, resulting in a 100% pass rate for foreign trade products and zero customer quality complaints.

Exhibition Engagement: Foreign Trade and Strength in Sync, Deepening Sino-Russian Cooperation

During the Wuhan and Shanghai exhibitions, Shandong Lutong, driven by both "Foreign Trade Services + Strength Demonstration," reached several significant cooperation agreements with Russian clients:

Reached preliminary intentions on annual procurement with partners, developed customized supply plans, and provided priority production and dedicated warehousing services to ensure continuity of the client's production operations.

Responded to specific performance requirements raised by clients by swiftly forming specialized teams, conducting in-depth discussions with technical experts, and committing to completing sample development within the stipulated timeframe through optimized product design and processes.

Established regular communication mechanisms with clients, providing periodic updates on production progress and logistics status. Combined with the client's equipment renewal plans, proactive spare parts stocking was arranged, significantly enhancing emergency response efficiency.

Client feedback: "Shandong Lutong's product quality is reliable, and their service team responds promptly to our needs. This efficient and flexible cooperation model gives us full confidence in our partnership."

Cooperation Deepening: Charting a New Blueprint for Drive Axle Technological Development

Through in-depth exchanges during the exhibitions, our company and the Russian clients reached multiple consensuses on future cooperation. Both parties decided to establish a regular technical exchange mechanism, sharing technological progress and market information quarterly via video conference. Simultaneously, a joint working group will be formed to co-develop a new generation of Drive Axle products suitable for the Eastern European market.

Regarding cooperation content, three key directions were identified: First, the development of Drive Axles specialized for extreme cold environments, focusing on technical challenges like low-temperature starting and anti-slip on ice and snow roads. Second, the R&D of intelligent Drive Axles, applying the latest sensor technology and control algorithms. Finally, improving the after-sales service system by establishing a more efficient spare parts supply and technical support network.

"We highly value our cooperative relationship with your company," stated the Russian client representative during the summary exchange. "Through our collaboration in recent years, we deeply appreciate your company's professional technical capabilities and sincere cooperative attitude. We look forward to further deepening our cooperation and jointly developing more market-competitive products."

Our General Manager also stated: "The Russian market is a vital component of our internationalization strategy. We will fully absorb the valuable suggestions from our clients and continuously improve our products and services. Meanwhile, we will translate the technical inspiration gained from visiting these exhibitions into innovation momentum, constantly advancing our company's technical level."

Future Outlook: Driving Enterprise Development through Technological Innovation

Although the PTC ASIA 2025 exhibition has concluded, the reflections and innovative sparks it ignited will continue. Through this deep exhibition engagement, our team not only grasped the latest industry technology trends but, more importantly, defined our future innovation direction and development path.

Regarding product technology, the company will further increase R&D investment, focusing on key technological breakthroughs in electric drive, intelligence, and lightweight design. Plans include launching the first intelligent Drive Axle product next year, enabling real-time status monitoring and intelligent early warnings; and completing the R&D and testing of electric Drive Axles by 2026, providing the market with green and efficient drive solutions.

In terms of manufacturing upgrades, the company will actively promote digital transformation, build smart factories, and enhance production efficiency and product quality. Plans involve introducing advanced production equipment and inspection instruments, and establishing a comprehensive quality traceability system to ensure every product leaving the factory meets the highest standards.

For international cooperation, the company will continue to deepen collaboration with Russian and other international clients to jointly develop products adapted to specific market needs. Concurrently, we will actively explore new international markets, promoting Chinese-manufactured Drive Axles to the world.

"This exhibition exchange has reinforced our belief that technological innovation is the foundation of enterprise development," summarized the company's General Manager. "We will take this exhibition as an opportunity to persistently advance technological innovation and quality improvement, providing customers with better products and services, and contributing more strength to industry development."