Shandong Lutong full series of loader drive axles are launched

In the fields of engineering machinery, agricultural machinery and mining machinery, the driving axle, as the core transmission component, its performance directly affects the operating efficiency of the equipment. In the fields of engineering machinery, agricultural machinery and mining machinery, loaders are indispensable equipment and are mainly divided into three categories: wheel loaders, crawler loaders and backhoe loaders according to their walking mechanisms and working devices. As a professional drive axle manufacturer, we have a deep understanding of the differentiated needs of different types of loaders for drive systems, so we have launched a full range of loader drive axles.

Three categories are accurately broken through, adapted to different loaders operating characteristics

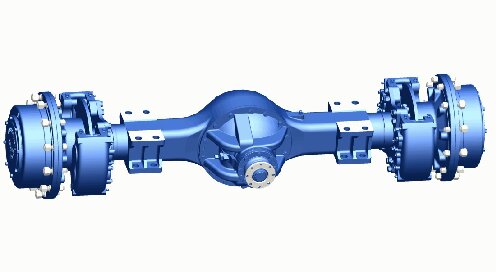

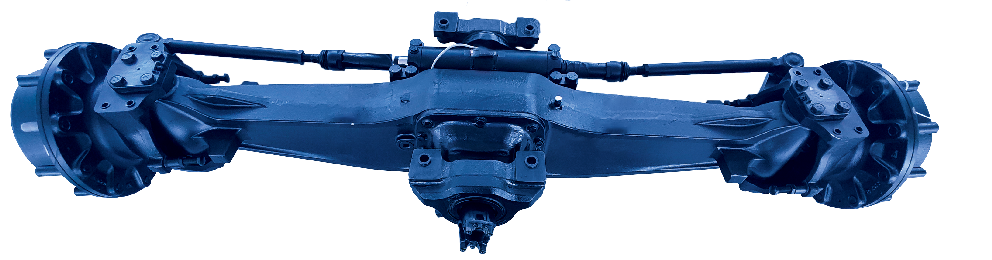

Wheel loader

The wheel loader adopts a tire walking mechanism, which has the characteristics of fast movement speed and flexible maneuvering. It is especially suitable for occasions where frequent transfers to construction sites are required. It adopts the design concept of "single working device + heavy chassis". Its front end is equipped with a large-capacity bucket, which can lift and unload the machine through a hydraulic boom. The entire machine structure is mainly linear layout, emphasizing operation stability. Wheel loaders are widely used in: material handling at construction sites, port container loading and unloading, agricultural product stacking, and urban infrastructure construction.

Especially for large-scale material handling such as large mines and building materials yards, wheeled loaders have become the first choice for high loading efficiency and long-distance transportation capabilities. Therefore, for wheel loader drive axles, high-speed stability, heavy-load adaptability and low-maintenance design are required. With years of experience in deeply rooting in the drive axle industry, Shandong Lutong's wheel loader drive axle has far exceeded the industry level. As an advantageous product, the 5-ton loader drive axle has gained the trust of many OEM manufacturers. We have all obtained cooperation with domestic OEMs in the top ten in the industry, such as Sany, Shantui, Liugong, Leiwo, etc. At the same time, our loader drive axles are also exported to Russia, and have also achieved long-term cooperation with many large OEMs such as PTZ and UMG. The accident rate of exported products is zero, and high-quality drive axles have obtained industry certification.

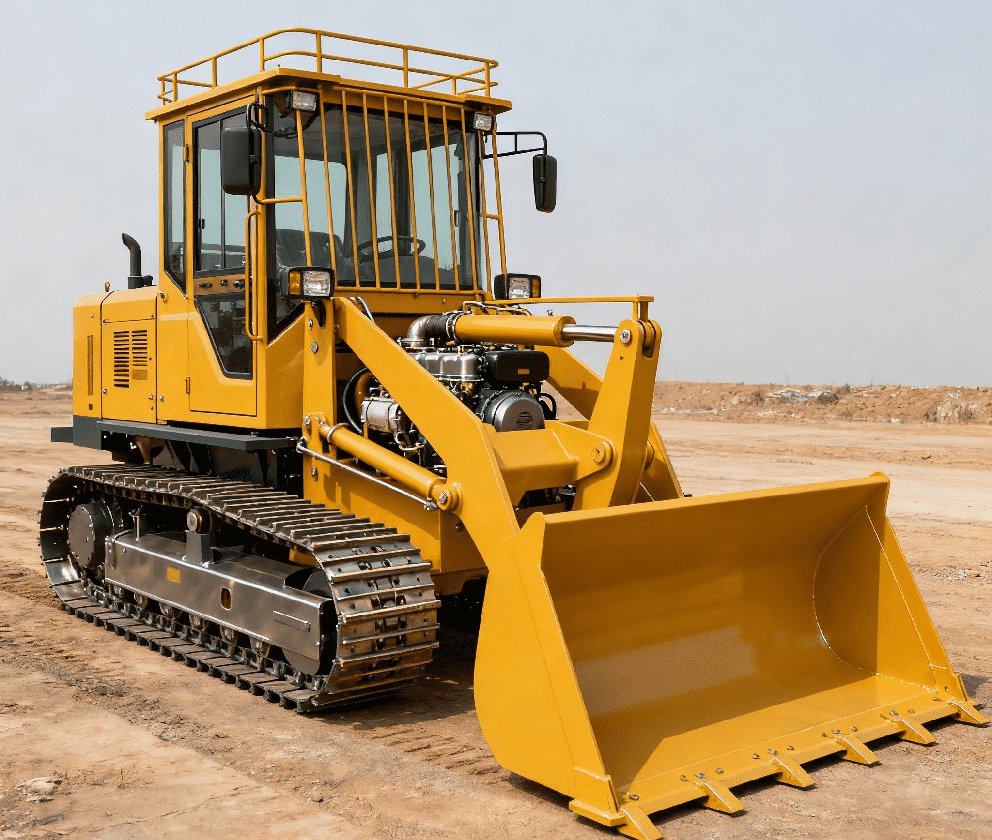

Crawler loader

The crawler loader is a construction machinery equipment based on the crawler walking system. The core functions are shoveling and loading, handling of sand, gravel, soil, ore and other bulk materials. It can also assist in site cleaning, foundation promotion and other operations. It is widely used in mining, infrastructure construction, farmland transformation, forestry operations and other scenarios. The crawler design has a large grounding area and a small grounding ratio. It can drive stably on muddy, soft or rugged ground, not easy to get stuck in the car, and is suitable for complex working conditions that are difficult to enter by wheeled equipment. The equipment is generally composed of a front-end bucket, a track walking mechanism, a power system and a control device. The bucket can adjust the angle and height through a hydraulic system to flexibly match different operating needs. It is a common equipment for material processing and basic operations in complex sites. However, the driving speed is slower than that of wheeled loaders and is mostly used in outdoor or complex working conditions.

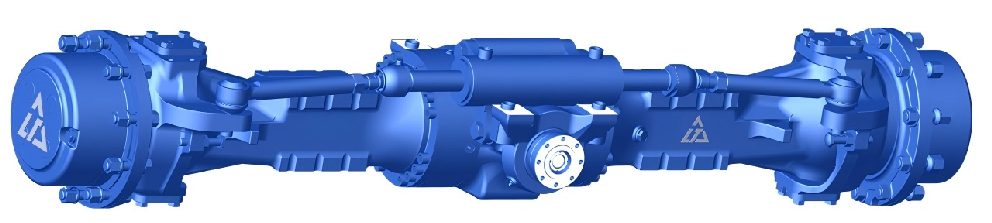

Backhoe loader

Backhoe loaders are a type of engineering machinery equipment with backhoe buckets as the core operating device. The core function is to excavate soil, sand, gravel, silt and other materials lower than the ground or operating plane. They can also assist in completing tasks such as material loading and unloading, ditches excavation, foundation pit repair, etc. It is a common equipment for small and medium-sized earthwork projects. Compared with front-shovel loaders, the backhoe loaders do not need to rely on high platform operations, and can directly dig foundation pits and pipe trenches lower than the ground. The bucket is backturned by a large angle, making the unloading more thorough. Compared with ordinary wheel loaders, it takes into account the functions of excavation and material handling, and does not need to be coordinated with excavators, which can reduce equipment investment; compared with crawler excavators, it has faster walking speed and high transition efficiency, and can also switch buckets, breakers and other accessories through quick change devices, making the operation scenario more flexible.

Our newly developed backhoe loader drive axle is designed for the backhoe's working conditions of "frequent start-stop, large load fluctuations, and both excavation and walking": it adopts a high-strength alloy shell, with a load carrying capacity of 15% higher than that of conventional drive axles, which can cope with instantaneous impact load during excavation; optimize the planetary wheel transmission structure, with a transmission efficiency of more than 96%, reduce power loss, and adapt to the dual needs of low-speed, high-torque excavation and high-speed transition of the backhoe; at the same time, the anti-leakage sealing system is integrated, and the service life is extended by 20% in muddy and dusty construction site environments, which can provide a stable and durable power transmission core for the backhoe loader, helping the equipment improve operating efficiency in small and medium-sized earthwork engineering, municipal maintenance and other scenarios.

Customized R&D + Strict Quality Control Build the core competitiveness of products

As a professional manufacturer who has been deeply engaged in the field of driving bridges for many years, Shandong Lutong has always taken "scenario adaptation" as its core research and development. Behind the launch of the full series of loader drive axles is the company's in-depth research on operating data in different industries - by collecting the actual operating parameters of nearly 1,000 loaders, establishing a driving axle performance model in segmented scenarios, and realizing a technological upgrade from "general" to "customized".

In the product quality control process, Shandong Lutong has established a full-process inspection system: from mechanical performance testing of raw materials entering the site, to dynamic load simulation testing during the production process, and then to 100-hour continuous full-load operation test before the finished product leaves the factory, ensuring that each drive axle meets the industry-leading reliability standards. At present, this series of products has passed ISO 9001 quality management system certification and a number of industry special inspections.

Empower efficient operations in multiple industries and embark on a new journey of transmission technology

"The performance requirements for the drive axle are very different in different types. Our goal is to match each loader with a 'tailed' transmission plan." Up to now, this full series of loader drive axles has been implemented in many domestic mining enterprises, municipal engineering companies and agricultural machinery cooperatives. In the future, Shandong Lutong will continue to focus on the research and development of core technologies of drive axles, and plan to launch an electric drive axle series for new energy loaders. At the same time, deepen cooperation with construction machinery and agricultural machinery OEMs, and provide integrated transmission solutions from design, production to after-sales service, creating higher operating value for global users.