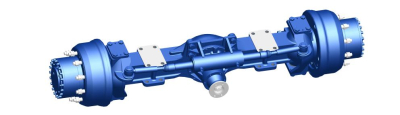

First Batch of Telescopic Handler Axles Successfully Delivered

SHANDONG LUTONG HEAVY INDUSTRIES MACHINERY CO.,LTD has successfully delivered its first batch of modular steering drive axles specifically developed for telescopic handlers to a renowned domestic OEM. The on-time shipment not only marks a significant breakthrough in the company’s industrialisation of new products but also demonstrates the rapid response capability of its modular manufacturing system. These innovative drive axles will be equipped on the latest generation of telescopic handlers, providing robust power support for logistics, warehousing, construction, and other sectors.

Intelligent Steering System: Redefining Equipment Mobility

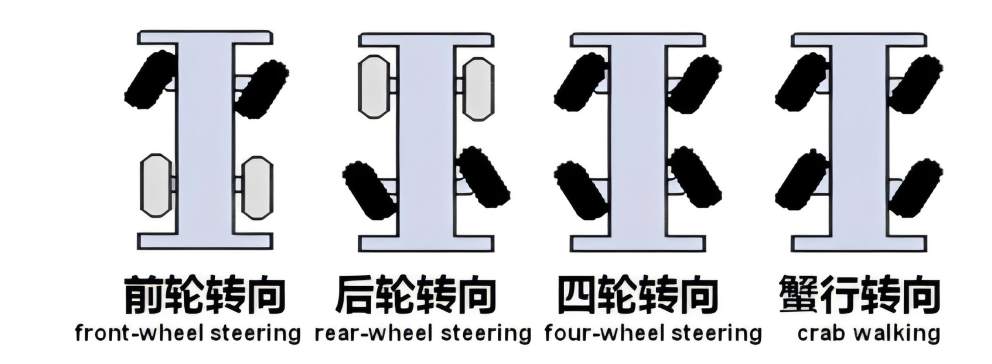

The delivered Telescopic Handler Axles represent the latest achievements in industry innovation. Designed to meet the high demands of telescopic handlers for comprehensive axle performance, this product breaks through traditional design limitations to achieve breakthrough improvements. Once installed, it supports three travel modes: front-wheel steering, four-wheel steering, and crab steering. This innovation significantly enhances mobility and operational flexibility in confined spaces.

In practice, operators can select the most suitable steering mode based on the working environment. Front-wheel steering ensures straight-line stability in warehouse aisles; four-wheel steering markedly reduces the turning radius in restricted sites; and crab steering proves particularly valuable for diagonal movement in special conditions. "The flexible switching between these three modes reduces equipment adjustments by over 40%, markedly boosting operational efficiency."

Wet Brake Technology: Delivering Ultimate Safety

For the braking system, this axle series adopts an innovative fail-safe wet brake design. Both front and rear axles are equipped with fully enclosed braking systems that completely isolate external contaminants like dust and mud. This design excels in high-dust environments such as mines and construction sites, substantially reducing the risk of brake failure due to contamination.Notably, the braking system demonstrates exceptional thermal management. Test data show that frictional heat generated during braking is rapidly absorbed by the oil and dissipated through the housing, avoiding the "thermal fade" common in dry brake systems. Under equivalent load conditions, the peak temperature of the wet brake axle can be 150-200°C lower than that of dry systems, ensuring consistent braking stability during continuous operation.From an economic perspective, although the initial cost of the wet brake system is about 30% higher than that of dry systems, its maintenance intervals are significantly extended, with friction material replacement frequency reduced by over 60%. This results in a 25-40% reduction in total lifecycle costs.

Differential Management System: Conquering Complex Conditions

To tackle various challenging terrains, this steering drive axle series is equipped with an advanced limited-slip differential and manual locking system. On muddy or loose surfaces, the limited-slip differential effectively suppresses wheel slip on one side to maintain traction; in extremely harsh conditions, the manual lock enables rigid wheel connection to ensure power is effectively delivered to each wheel.

One customer reported in trial feedback: "At the mining site, this differential management system demonstrated exceptional performance. Even on muddy slopes, the equipment maintained stable traction, greatly enhancing overall mobility and operational capability." This technical advantage allows equipped handlers to adapt to diverse complex conditions, from warehousing and logistics to mining operations.

Modular Design: Rapid Response to Customer Needs

The delivered axles adopt a modular design concept, supporting rapid customisation based on customer requirements. To ensure timely delivery, the company implemented a lean production system with ample raw material reserves and highly efficient production lines. The quality department enforced end-to-end quality tracking, with strict control points from raw material intake to finished product shipment. We prioritise not only delivery speed but also ensuring every product meets the highest quality standards.

Customer Recognition: Earning Market Trust Through Excellence

The first batch immediately received high praise from customers. One stated: "Lutong Heavy Industry’s rapid response and product quality exceeded our expectations. The timely arrival of these axles ensured the smooth progress of our production schedule."The technical service team is fully prepared to provide comprehensive support, including installation guidance, commissioning services, and subsequent maintenance training. The complete service system fully meets customer needs for training, service, and spare parts.

Looking Ahead: Continuous Innovation Driving Industry Progress

This successful delivery is just the beginning. The R&D department has already commenced development of next-generation products, focusing on electrification and intelligentisation. We will continue to deepen the modular design philosophy and develop more products tailored to market demands.

With these axles now in use, we expect to see increased adoption of this innovative technology by more OEMs. We have already received inquiries from multiple manufacturers and are actively preparing for subsequent batch production. In the future, we will develop more telescopic handler axles to complete the product series.

Shandong Lutong remains committed to creating value through technological innovation. The successful delivery of these steering drive axles reaffirms the company’s R&D strength and manufacturing excellence in the field. Moving forward, we will continue to uphold the principle of "Quality First, Customer Foremost" to provide the industry with more high-quality products and technical solutions.