12 Ton Wheel Excavator Drive Axle

1. Product quality is comparable to international brands

2. Supply to many leading domestic OEM factories

3. Product quality warranty

4. Large stock, price discount

5. Services can be customized according to requirements

Introduction:

In the field of engineering machinery, the drive axle, as the core transmission component, is directly related to the power transmission efficiency, stability and service life of the equipment. Our 12 ton wheel excavator drive axle is specially designed for small and medium-sized wheeled excavators, taking into account high-strength operation needs and flexible maneuverability. It is suitable for a variety of complex working conditions such as mines, construction, and municipal affairs.

The 12 ton wheel excavator drive axle integrates high-strength gear sets, optimized differentials and efficient braking systems, which significantly reduces energy consumption while ensuring torque load-bearing capacity. The bridge shell has been strengthened through integrated casting technology and finite element analysis, and its impact resistance is improved by 30%, effectively coping with frequent vibrations under rugged terrain. In addition, sealing upgrades can adapt to extreme environments and reduce maintenance frequency.

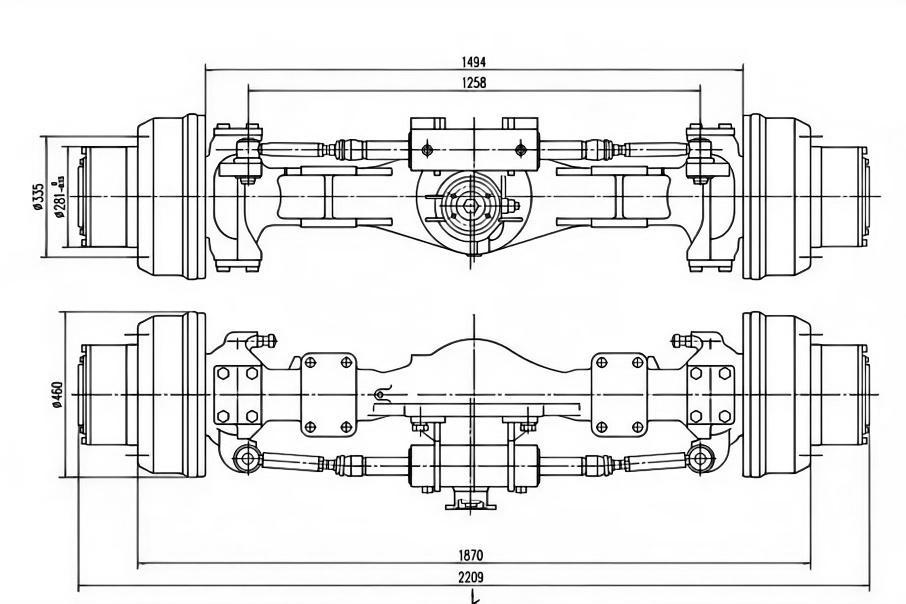

Main technical parameters:

Total transmission Ratio | 16.89 |

Maximum input torque | 2535N.m |

Rating load | 13000Kg |

Term of turning | Hydraulic steering |

Braking oil pressure | 12.5MPa |

Single braking moment | 10900N.m |

Single brake caliper capacity | 14ml |

Oil request for driving axle (API standard) | GL-5:85W/90 Gear Oil (above -12℃) GL-5:80W/90 Gear Oil (above -26℃) |

Oil request for brake | L-HV46 Wear resistant and low coagulation hydraulic oil |

The dimensions of input flange | 4-Ø12.2 distributes Ø110 of circle, concave |

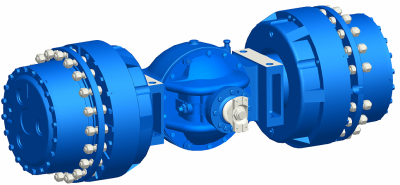

The wheel side reduction system adopts the industry's mature NGW-type planetary transmission structure. The structure has a large transmission ratio, small size and strong load-bearing capacity. It can further reduce the power transmitted from the main reducer to increase torque, so that the wheels can obtain a larger driving torque, and adapt to the heavy-load operation needs of 12 ton excavator.

Compared with the traditional fixed-axis wheel system reduction structure, the power distribution of NGW-type planetary deceleration is more uniform. When the planetary wheel rotates around the sun gear, multiple teeth mesh and stress are simultaneously reduced, which reduces the wear of the wheel edge gear. At the same time, the structure adopts a fully sealed design to avoid cross-contamination of lubricant oil, extend the service life of the wheel edge gear, and reduce the frequency of wheel edge maintenance. After testing, the power output stability of the 12 ton wheel excavator drive axle equipped with this structure is improved by 15% under heavy load conditions, avoiding wheel slippage and power interruption.

Our company has been focusing on the manufacturing of engineering machinery drive axles for more than 30 years, and its strength is firmly at the forefront of the industry: it has two intelligent production lines equipped with German Siemens PLC control system, realizes automatic processing of key processes of drive axles, with a detection accuracy of 0.001mm, and a product pass rate of more than 99.8%;

A technology R&D center has been built, and the core R&D personnel have more than 10 years of design experience and have obtained a number of patents for driving axles-related utility models. The company has passed the certification of major systems and has achieved long-term cooperation with many OEM factories such as Sany, Shantui, Liugong, and Leiwo. International products occupy a stable share in the Russian and Central Asian markets, and have provided driver axle supporting services for Russian local brands UMG, PTZ, etc. Our products have shown excellent performance in Russia and achieved good results with zero accident rate.

In view of the operational pain points of the 12 ton wheel excavator drive axle, we formed a special R&D team to complete the iterative design of the drive axle - referring to the actual operation data of the customer, optimized structural details, and finally passed the bench simulation test and 500-hour field operation verification to launch this drive axle with wide adaptability, strong durability and reliable performance, committed to helping customers solve core component failure problems and compress operating costs.

We know that for your business, what is important is not only product price, but also reliability, local adaptability and efficient service. Our company can provide you with:

Logistics and Services: Provides you with safety and convenience. Goods sent abroad not only require high-quality products, but also reliable logistics guarantee:

Packaging protection: Use a solid wooden box with moisture-proof coating to effectively avoid collision and damage during transportation and temperature and humidity changes;

Logistics Partner: Cooperate with logistics companies - Short delivery time, goods can be received within 30 days

Customs declaration service: We have professionals to follow up on customs declaration procedures throughout the process

In addition, we have created an exclusive service support system for customers:

1. Professional technical consultants provide communication services, and provide English version of the operating manual and structural diagram

2. After-sales guarantee, stock of regular spare parts, which can quickly respond to maintenance and replacement needs

3. Customize exclusive solutions for your device model;

4. Flexible payment terms for large-scale orders;

If you need products, please contact us and we will have sales staff for you 24 hours a day. At the same time, Shandong Roadway invites you to visit the production base and conduct on-site inspection of quality.