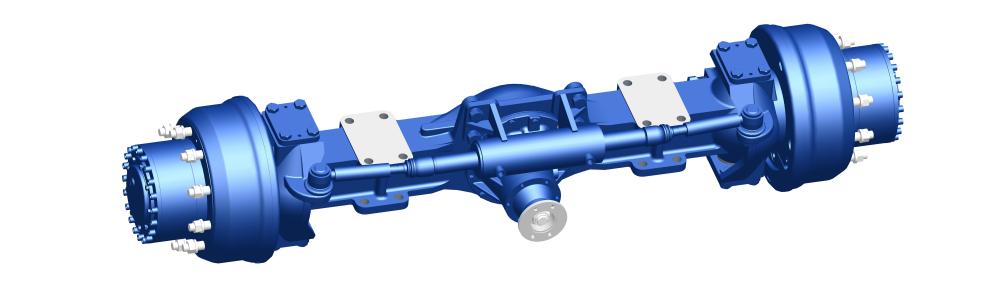

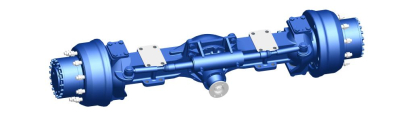

12 Ton Steering Drive Axle

1.Proven product, long-validated by the market.

2.Ample inventory, short lead times.

3.Key components from renowned brands, extended service life.

4.Customized production according to requirements.

Introduction:

Designed for 8-12 ton wheel excavators, this 12 ton steering drive axle is a highly versatile product. We developed it based on real-world operational feedback, and it has gone through years of technological refinements to reach its current form. Today, it’s widely used by top OEMs—and it consistently delivers strong overall performance.What makes this axle stand out? It strikes a smart balance between two key needs: low-speed operation and high-speed mobility. When the excavator is tackling heavy-duty jobs like digging or lifting, the axle puts out steady, high torque and plenty of power to get the work done. And when the equipment needs to move between job sites, it lets the machine travel at higher speeds. This not only boosts overall operational efficiency but also helps the axle fit perfectly with the complex, ever-changing working conditions that wheel excavators face.

As the key assembly for excavators to deal with complex construction sites, the drive axle, transmission and braking systems are coordinated to achieve the core needs of loss resistance, efficient force transmission and safety and stability.

Bridge shell: Strong load-bearing and damage resistance are integrally cast with high-strength alloy, combined with finite element analysis and optimized structure and stress simulation test, the key stress parts are additionally strengthened, greatly improving impact and fatigue resistance, and adapting to strong vibration and high impact conditions on the construction site.

Transmission system: The high-efficiency and durable force transmission gear pair is finely matched with module-digital tooth shape + precision grinding to optimize meshing and tooth surface smoothness; it not only improves power transmission efficiency, but also enhances the gear torque bearing and life, and still maintains stable force transmission under extreme loads.

Braking system: Safe and stable braking is equipped with hydraulically controlled normally closed hoof-shaped wheel-side brake, which has high braking torque and fast response. Whether it is parking on slope or emergency braking, it can quickly ensure the safety of the equipment.

We don’t cut corners on critical components, either. Parts like bearings and oil seals in this 12 ton steering drive axle come from well-known international brands, so we guarantee durability and reliability right from the start. During manufacturing, every machined part goes through precision testing in a temperature-controlled 3D inspection room. This ensures that all dimensional and geometric tolerances match our design specs exactly—keeping product consistency high and making assembly and part replacement easy.

Plus, the drive axle offers multiple options for mounting and connection sizes. We can also customize it to fit the chassis interface and performance needs of different OEMs, which makes it much more adaptable and convenient for manufacturers to use. Thanks to its tough materials, strict manufacturing standards, and extensive real-world testing, this mature 12 ton steering drive axle has become a trusted choice for many OEMs both at home and abroad. Users consistently praise it for its high availability, low maintenance costs, and great value for money.

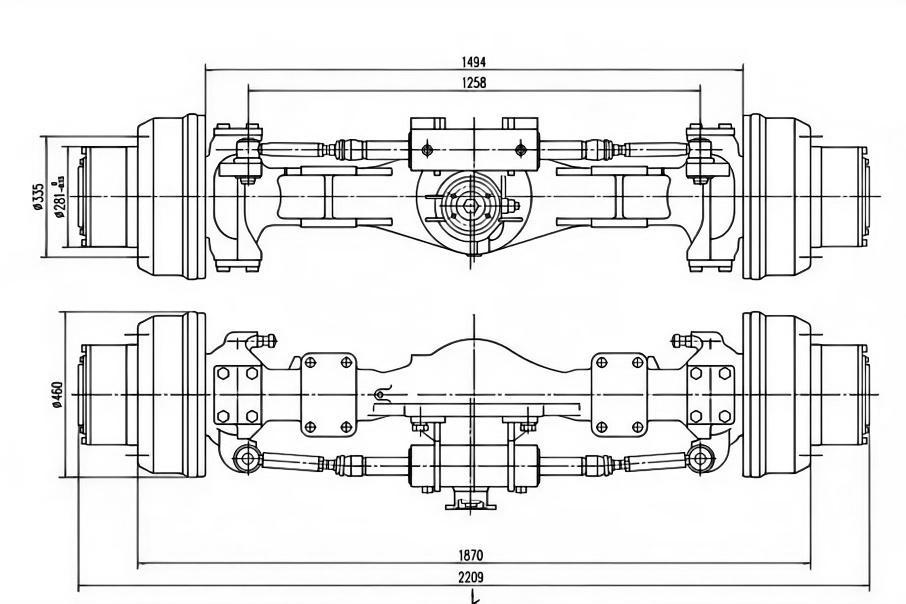

Main technical parameters:

Total transmission Ratio | 16.89 |

Maximum input torque | 2535N.m |

Rating load | 13000Kg |

Term of turning | Hydraulic steering |

Braking oil pressure | 12.5MPa |

Single braking moment | 10900N.m |

Single brake caliper capacity | 14ml |

0il request for driving axle (API standard) | GL-5:85W/90 Gear 0il (above -12℃) |

| L-IIV46 Wear resistant and low coagulation hydraulic oil |

The dimensions of input flange | 4-Ø12.2 distributes Ø110 of circle, concave coupling element Ø80H9 depth 3 |

Steering Drive Axle Product Series

Our company doesn’t just stop at this 12 ton model—we offer a wide range of steering drive axles that work with 10-15 ton wheel excavators. For the braking system, you can choose from disc caliper, drum, or wet types. And for the axle itself, we have both integrated and modular designs available. Manufacturers can pick the configuration that works best for them, and we can even customize any product to meet specific requirements.

What’s more, our steering drive axles are flexible enough to be used beyond excavators. They can be adapted for special machinery like log loaders, aerial work platforms, telescopic handlers, and backhoe loaders too.

We also have a professional technical service team that provides support throughout the entire product lifecycle—from helping you choose the right axle and installing it, to debugging, training your team on how to use it, and handling after-sales maintenance. On top of that, we’ve built a comprehensive spare parts supply system. This lets us respond quickly to customer needs and keep your equipment running without unnecessary downtime.

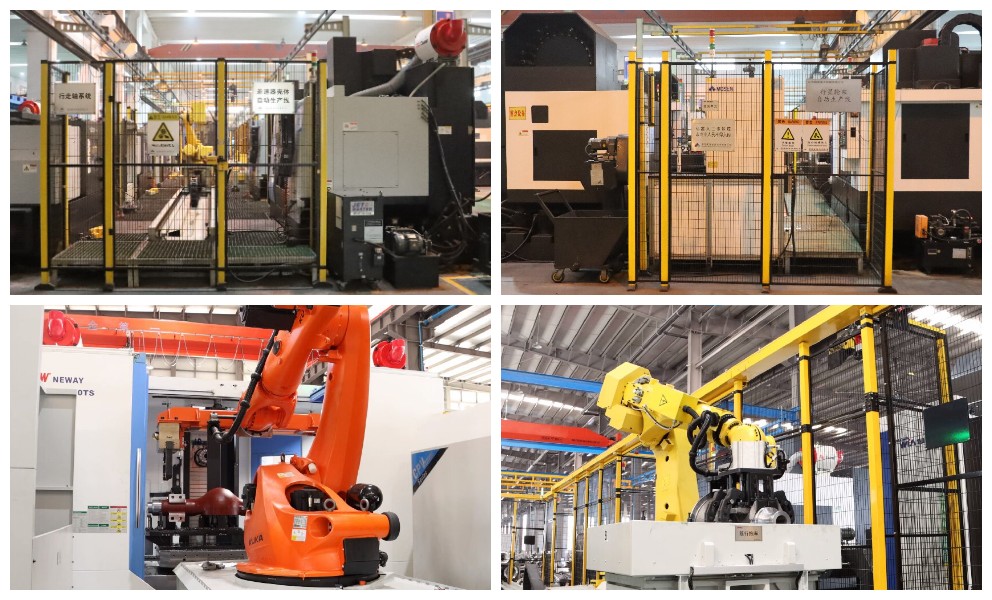

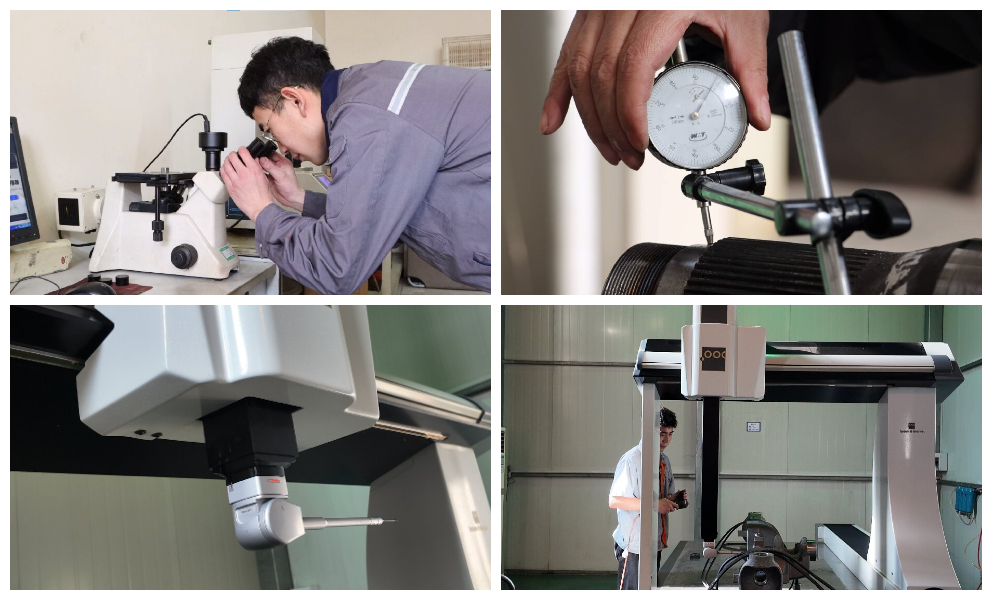

Company Facilities

The company is equipped with numerous advanced facilities, and key processes have been automated with intelligent CNC operations.

Quality Management

We employ industry-leading inspection equipment, including coordinate measuring machines (CMMs), digital metallurgical microscopes, and ultrasonic flaw detectors. A comprehensive total quality management system is implemented with full participation across all levels.

Sales and Service

We are committed to providing customers with the highest value products and superior service. Our products are sold both domestically and internationally, with long-term stable supply to over 100 domestic customers and exports to countries and regions including Russia, Belarus, and Iran. The company has dedicated after-sales service spare parts warehouses and technical teams to ensure rapid response to customer needs.