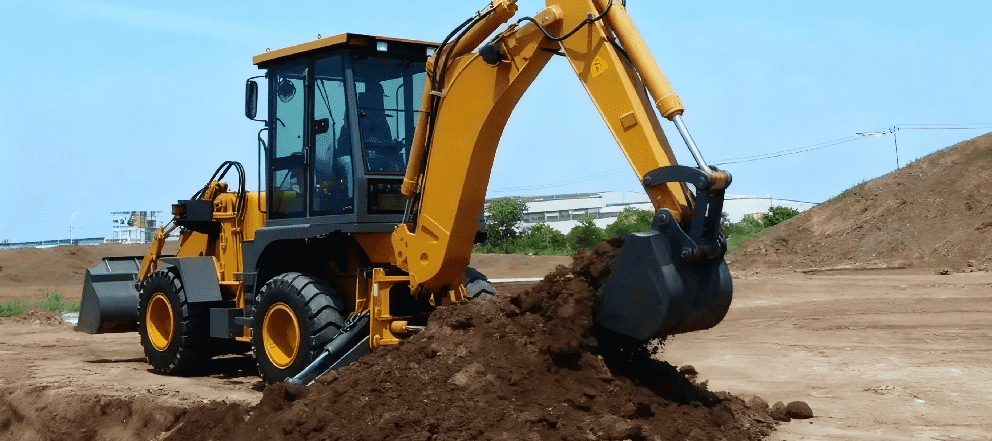

Backhoe Loaders Drive Axle

1.Rapid delivery ensuring project timelines.

2.Low failure rate with extended service life.

3.Direct factory supply eliminating middleman markups.

4.Adequate stock for immediate production needs.

Introduction:

This backhoe loader drive axle is purpose-built for backhoe loaders—an established, mature product crafted from deep hands-on experience with real-world operations and a focus on what users actually need. It puts three priorities front and center: maximizing uptime, ensuring safety, and adapting to job site demands. And when you put it to work, it delivers standout performance in real-world scenarios.

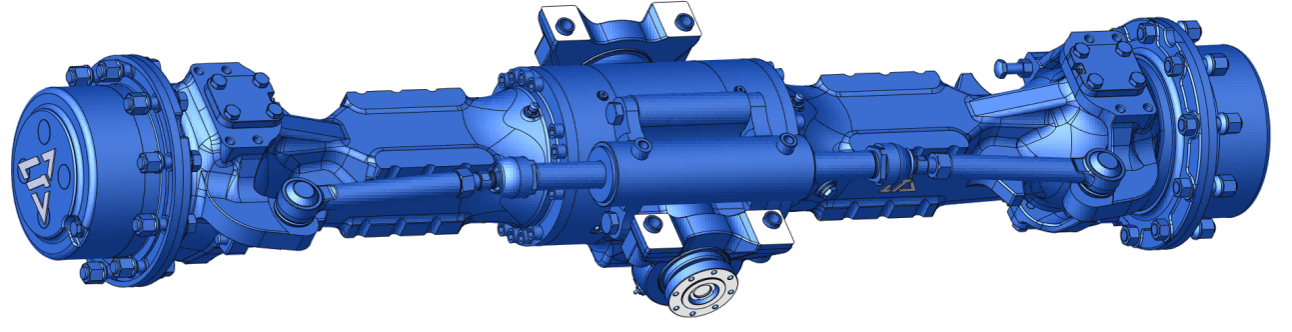

As a rear axle for backhoe loaders, it features an oscillating frame design with a low center of gravity. This does more than just optimize weight distribution and boost stability—it also cuts down on tipping risks significantly when the machine is tackling heavy tasks like digging or lifting. That’s a big win for worksite safety, plain and simple. What’s more, the axle’s structure is fully aligned with the host machine’s digging functions, so power flows smoother and operations stay better coordinated.

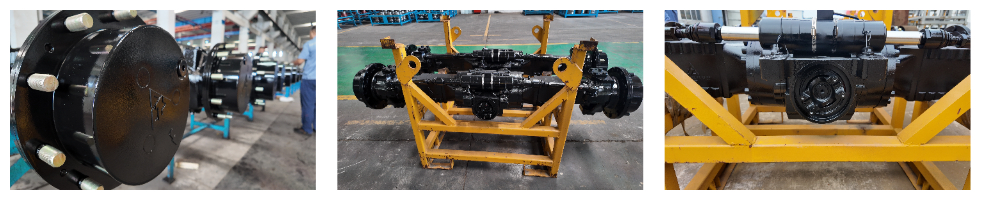

When it comes to safety and handling tough terrain, this axle has you covered. It comes with a fail-safe wet brake system that kicks in fast, giving you reliable stopping power even in emergencies—protecting both your equipment and your team. There’s also a limited-slip differential (LSD) with a manual locking system: when wheels start to slip, the differential automatically adjusts torque distribution to keep traction steady. And for extreme terrain, the manual lock lets you rigidly connect the wheels, which makes a huge difference for mobility and climbing ability in muddy or rough conditions. These top-tier features stop wheel slip in its tracks and keep traction consistent, no matter the job.

Another key feature? This axle can double as a rear steering unit. It works with the machine’s existing steering system to enable four-wheel steering, so operators can pick between front-wheel, four-wheel, and crab steering modes depending on how much space they have. That means agile turns and easy maneuvering even in super tight areas—no more repeated adjustments. The result? Better efficiency and easier operation—real advantages for anyone using the machine.

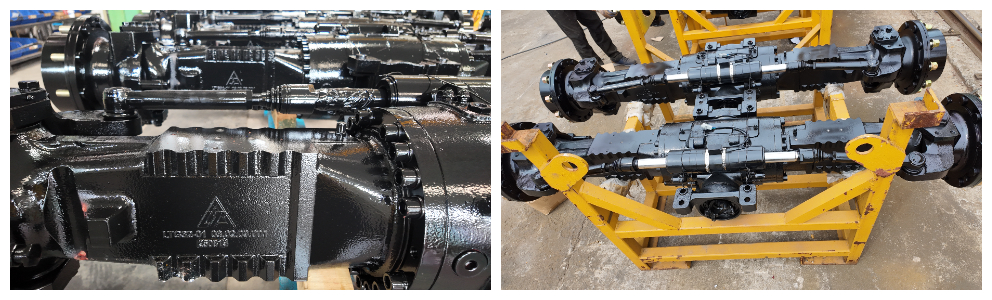

Thanks to its modular design and high part commonality, this axle can be quickly adapted into variants with different connection dimensions. That checks all the boxes for diverse OEM needs, while also shortening development cycles and getting products delivered faster. Between its tough build, multi-layered safety features, strong mobility, and broad platform compatibility, this drive axle is a reliable, efficient solution for high-end backhoe loader chassis systems. It gives machines the solid support they need to perform well across all kinds of working conditions.

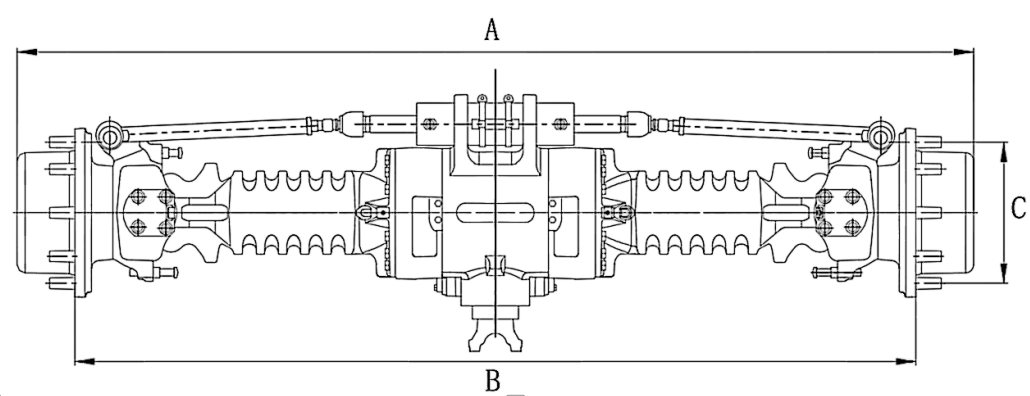

Main technical parameters

Model | LTG27 | LTG32 | LTG43 |

A: Rim mounting distance(mm) | 1920、2050、2180 | 1950 | 1950 |

B:Rim mounting dimensions | 8-M18x1.5 on ø 275 | 10-M22x1.5 on ø 335 | 10-M22x1.5 on ø 335 |

Total ratio | 14.3-23.3 | 17.1-23.3 | 17.1-23.3 |

Max steering angle | 55° | 55° | 55° |

Brakes | Wet multi-disc | Wet multi-disc、 Service and parking | Wet multi-disc、 Service and parking |

Differential | Limited slip system Differential lock | Limited slip system Differential lock | Limited slip system Differential lock |

Maximum output torque (N.m) | 27000 | 32000 | 43000 |

Dynamic load (kg) | 8800 | 10500 | 12000 |

Static load (kg) | 22000 | 26250 | 30000 |

Lift capacity (kg) | 4000 | 4500 | 5000 |

Vehicle no-load mass (kg) | 8500 | 10500 | 12500 |

Application Scenarios

While it’s mainly designed as a rear steering axle for backhoe loaders, its modularity and platform compatibility make it a fit for other equipment too—like aerial work platforms, wheeled excavators, and telescopic handlers. If you’re thinking about using it for something beyond backhoe loaders, just reach out to us. Our engineers will run precise calculations and do field assessments to check feasibility, then craft a solution that’s tailored to you.

Technical Support and Service Assurance

We offer full technical support and customization for OEM clients. With over 30 years in drive axle R&D and manufacturing, we’ve got mature capabilities for forward development and collaborative design. Whether you need to adapt axle assemblies to match your host machine’s layout, power system, or specific functions, we can do it quickly—no long waits.

Throughout the product’s life cycle, we provide professional technical consulting, installation guidance, and debugging support to make sure the axle integrates perfectly with your machine. We also have a strong quality traceability system and after-sales service setup: we keep a steady supply of spare parts on hand and respond fast, so you can expand into overseas markets with confidence. If you’ve got project-specific needs, just get in touch with our engineering team to talk through the details of how we can work together.

Quality Control and Testing Certification

Product quality and reliability are our top commitments. Every step of production follows ISO 9001 quality management standards, and we source key components from trusted domestic and international suppliers. We track everything—from raw materials and heat treatment to precision machining and final assembly—so there’s full traceability. We also help OEMs with product compatibility testing and reliability checks, and we provide complete technical documents and test reports to back it all up.

Company Facilities

The company is equipped with numerous advanced facilities, and key processes have been automated with intelligent CNC operations.

Quality Management

We employ industry-leading inspection equipment, including coordinate measuring machines (CMMs), digital metallurgical microscopes, and ultrasonic flaw detectors. A comprehensive total quality management system is implemented with full participation across all levels.

Sales and Service

We are committed to providing customers with the highest value products and superior service. Our products are sold both domestically and internationally, with long-term stable supply to over 100 domestic customers and exports to countries and regions including Russia, Belarus, and Iran. The company has dedicated after-sales service spare parts warehouses and technical teams to ensure rapid response to customer needs.