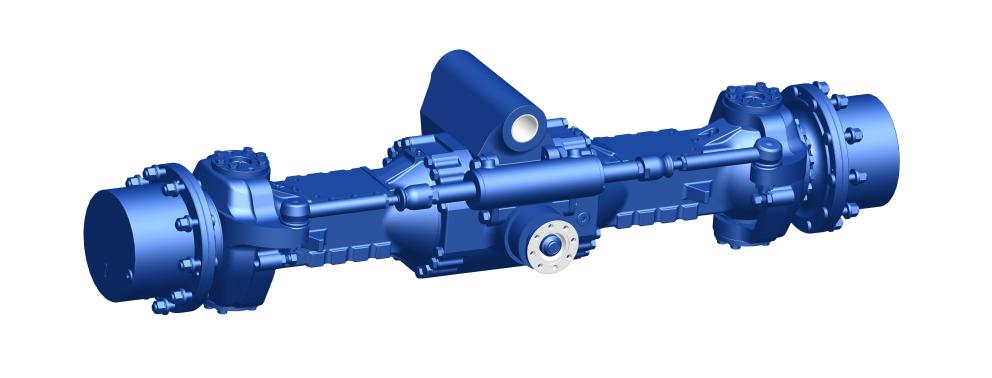

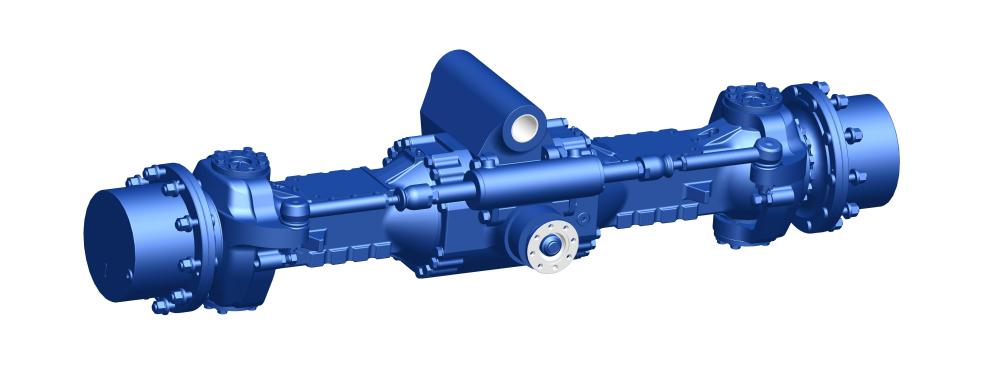

Steering Drive Axle

1. A two - stage reduction transmission structure is utilized in this bridge.

2. Equal - height tooth cycloidal bevel gears are used for the main reduction. These gears have characteristics such as high gear strength, high transmission efficiency and low noise.

3. An NGW - type planetary reduction transmission mechanism is adopted on the wheel side. Its design is reasonable and compact.

4. Flexible operation is made possible by hydraulic power steering.

5. The bridge housing is cast from nodular cast iron, which endows it with good rigidity and a large load - bearing capacity.

6. A closed multi - disc wet brake is employed. It uses hydraulic pressurization and spring release, guaranteeing stable braking performance as well as high safety and reliability.

Introduction :

The steering drive axle is a key transmission component designed specifically for 13-16 ton wheeled excavators. It features a two-stage reduction transmission, a hydraulic power-assisted steering system, and a closed multi-disc wet brake system. It combines three essential functions: steering, driving, and braking. Its primary task is to transfer power from the transmission to the wheels, converting it into driving force. Simultaneously, it ensures flexible steering and reliable braking during operation, fully meeting the heavy-load and high-maneuverability requirements of construction machinery under complex working conditions.

Main technical parameters:

Total transmission Ratio | 16.91 |

Maximum Output torque | 50000N.m |

Dynamic load each axle | 13000Kg |

Braking torque(single side) | 21000N.m |

Braking oil pressure | 4Mpa |

Braking displacement | 45-128ml |

Angle of turning | 32/25° |

Steering cylinder pressure | 14Mpa |

0il request for driving axle(API standard) | GL-5:85W/90 Gear 0i1(above -12 ℃) |

Brake and cylinder oil | L-HLA6 hydraulic oil |