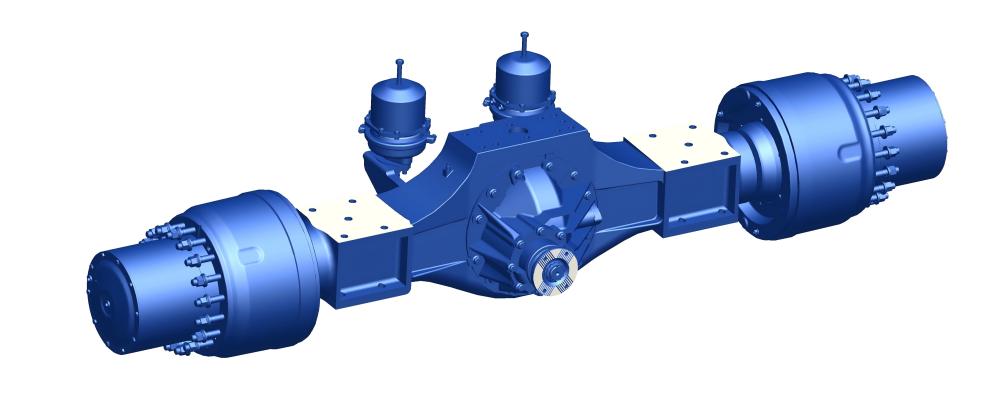

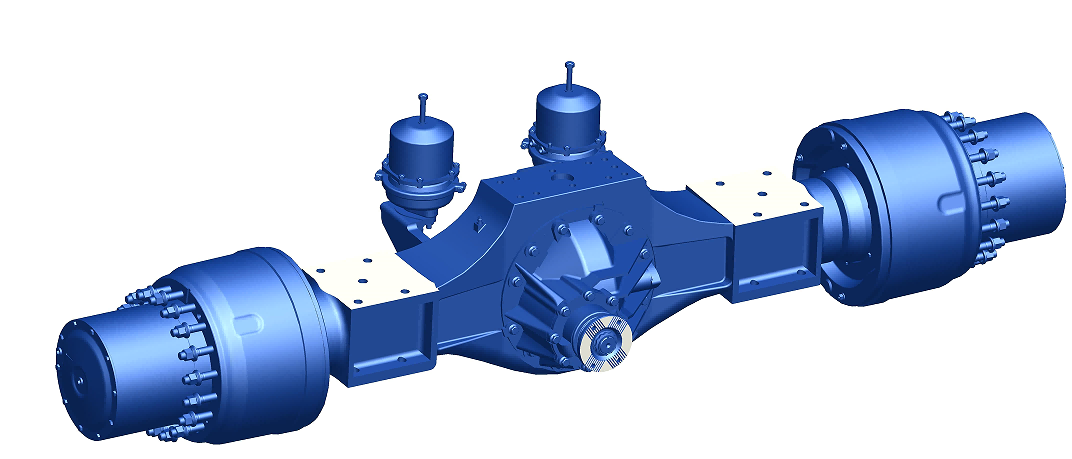

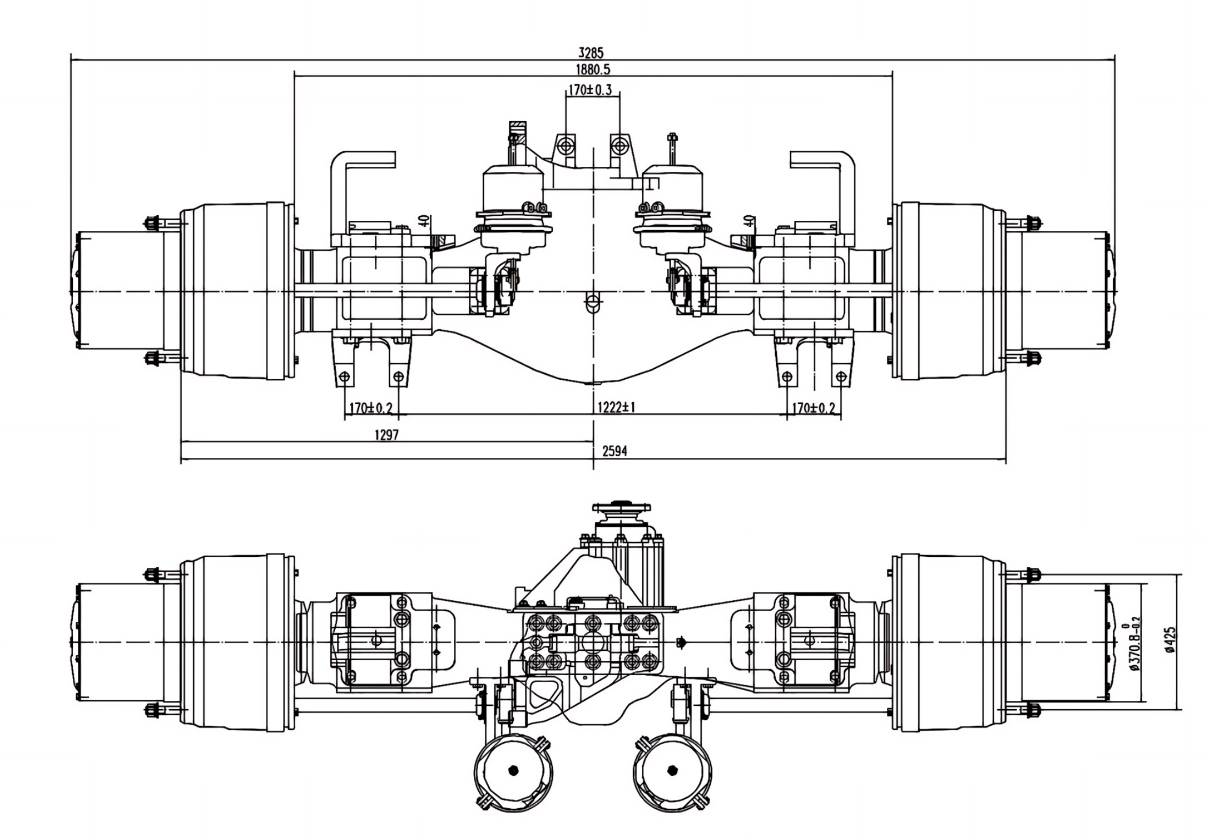

Mining Truck Drive Axle

1. High braking torque with rapid, dependable stopping.

2. Wheel-mounted NGW-type planetary reduction gearing-compact, optimized design.

3. Reinforced leaf spring connections for high load capacity.

4. Constant-height spiral bevel gear final drive optimizes efficiency while minimizing noise.

5.Usually installed on 105-ton mining trucks as the rear axle

Introduction:

Engineered for wide-body mining trucks, this integrated drive axle system features a monolithic cast steel housing with constant-height spiral bevel final drive and NGW planetary wheel reduction. A dual-function internal expanding brake combines service/parking braking.

Main technical parameters:

Overall gear ratio | 16.641 |

Maximum input torque | 12200N.m |

Rated load | 40000Kg |

Brake specifications | Φ500×250 |

Brake chamber specifications | 36/30 |

Brake air pressure | 0.8MPa |

Overall axle braking torque | 90000N.m |

Drive axle lubrication requirements | GL-5:85W/90 Gear Oil(above -12 ℃) |

Maintenance

When maintaining axles in construction machinery, the "prevention-first, enforced maintenance" principle must be followed. By carrying out regular cleaning, scheduled lubrication, tightening, and component inspections, latent problems can be identified and resolved promptly, stopping small defects from evolving into major damages—including severe incidents like bearing seizures leading to gear teeth wear or axle fractures. Recommendations include developing a tailored maintenance schedule according to how often the equipment is used and its working conditions, and prioritizing OEM components to ensure consistent axle performance and prolong the equipment’s lifespan.