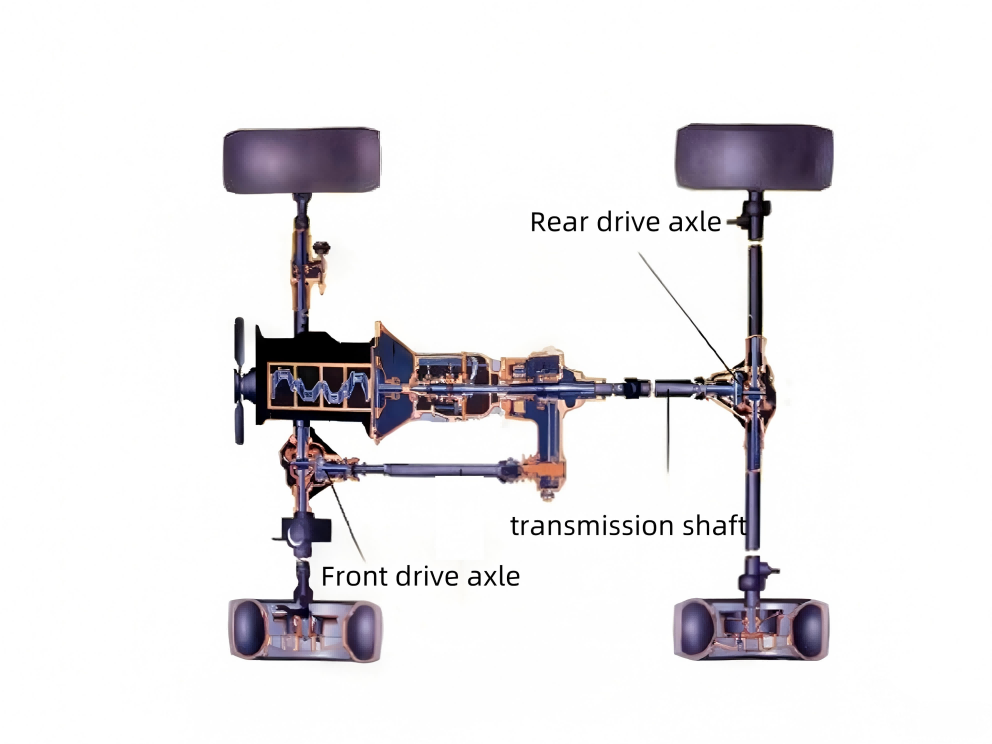

Is drive shaft and drive axle the same thing?

In the heavy machinery industry, the terms "driveshaft" and "drive axle" are often confused, leading to misunderstandings among procurement personnel and engineers. Driveshafts are categorized by cross-sectional shape into solid and hollow shafts, while drive axles are classified by application—such as loader axles, excavator axles, and motor grader axles in construction machinery. Though both components are critical for power transmission in vehicles and equipment, their functions differ significantly. This article clarifies these differences and their roles in construction, agricultural, and mining equipment.

Design and Application

Driveshafts are typically used in vehicles with longer wheelbases, while drive axles are core components of heavy machinery requiring high load-bearing capacity, such as excavators and harvesters.Driveshafts and drive axles are distinct concepts. Correct component selection significantly enhances equipment performance and service life. As a specialized manufacturer of drive axles for construction, agricultural, and mining equipment, clarifying these differences helps customers choose the most suitable components. Shandong Lutong’s high-performance drive axles are engineered for extreme conditions, meeting rigorous demands for durability and efficiency. For customized solutions, explore our industrial drive axle product series.

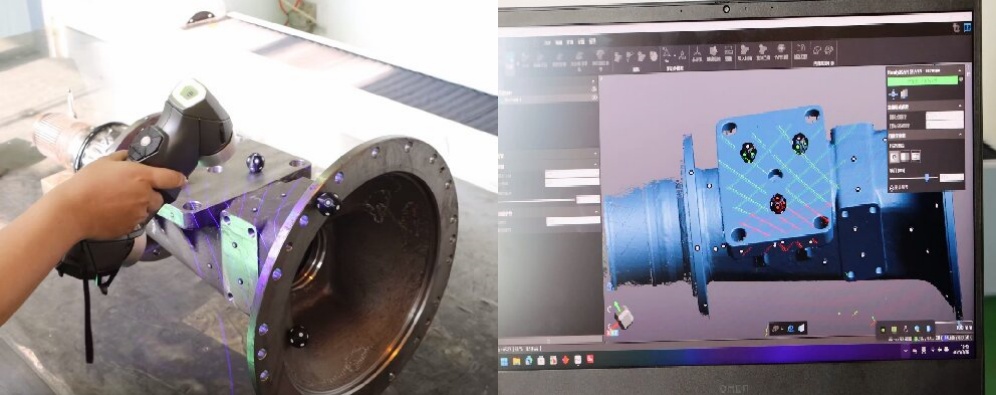

Leveraging Shandong’s equipment manufacturing industry advantages, Shandong Lutong has established an R&D center equipped with world-class production and testing equipment. Our engineering team continuously breakthroughs technological bottlenecks, achieving advancements in materials science, heat treatment processes, and structural optimization. Through digital simulation design and intelligent production techniques, we ensure every drive axle delivers exceptional fatigue resistance and extended service life. Our products undergo precise calculations and rigorous testing to adapt to various complex conditions—such as high-load operations and harsh environments—significantly enhancing equipment longevity and operational efficiency.

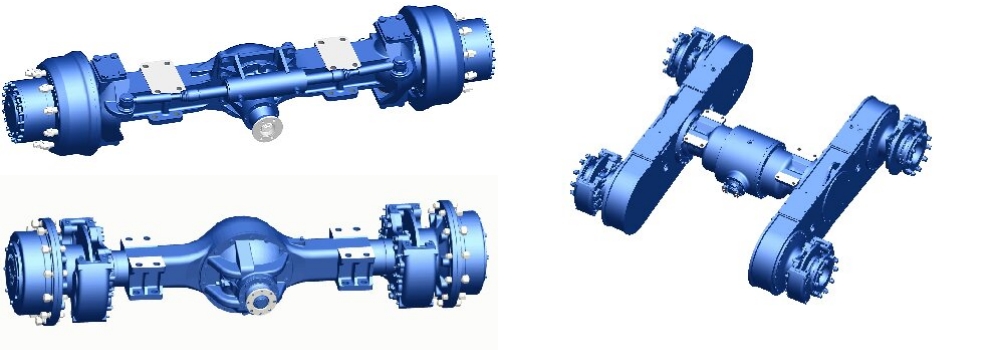

Comprehensive Product Portfolio for Diverse Applications

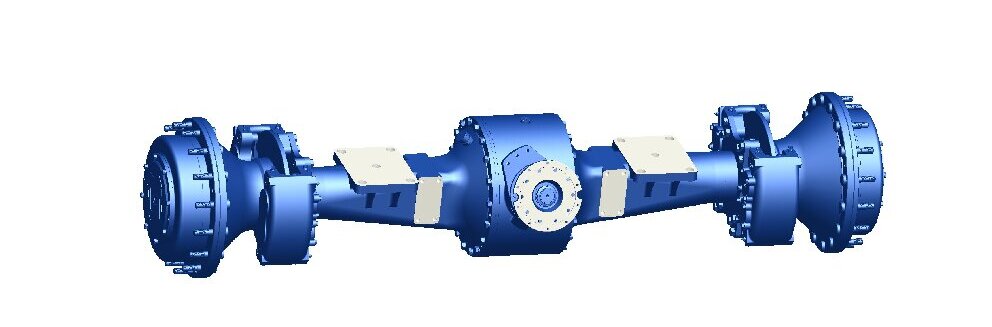

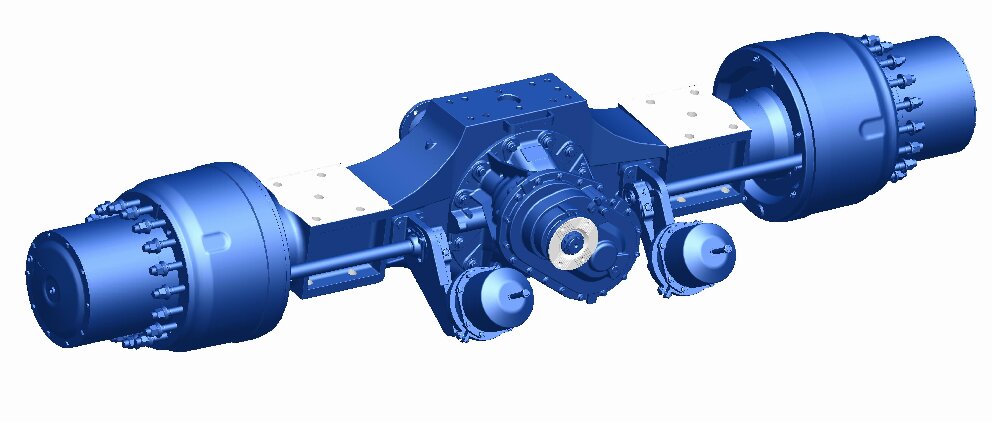

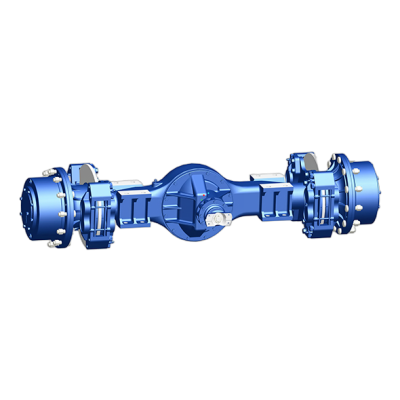

For construction machinery, Shandong Lutong has developed loader axles, excavator axles, and motor grader axles. Our loader axles feature proprietary axle-end locking structures and dual-modulus gear pairing technology, achieving transmission efficiency up to 96% and noise levels below 85 dB. They are suited for complex conditions in large infrastructure projects, such as those in Siberia, Russia.

In agricultural machinery, our drive axles cover the 350-430 hp range, optimized for traction in muddy fields and uneven terrain. With sealed braking systems and anti-corrosion coatings, they resist mud and water erosion in agricultural operations, extending maintenance intervals to 1.5 times those of conventional products. The customized T400 high-horsepower tractor axle for Russia is supplied to major OEMs like PTZ, with whom we have established a long-term partnership and maintained a zero-failure rate.

For mining applications, our axles feature reinforced housing designs and multi-disc wet brakes to handle heavy loads and long descents. With a single-axle load capacity of up to 50 tons, they are ideal for heavy-duty transport vehicles in large mining areas like the Kursk Iron Mine in Russia.All products can be customized to specific client parameters, supported by professional technical selection guidance.

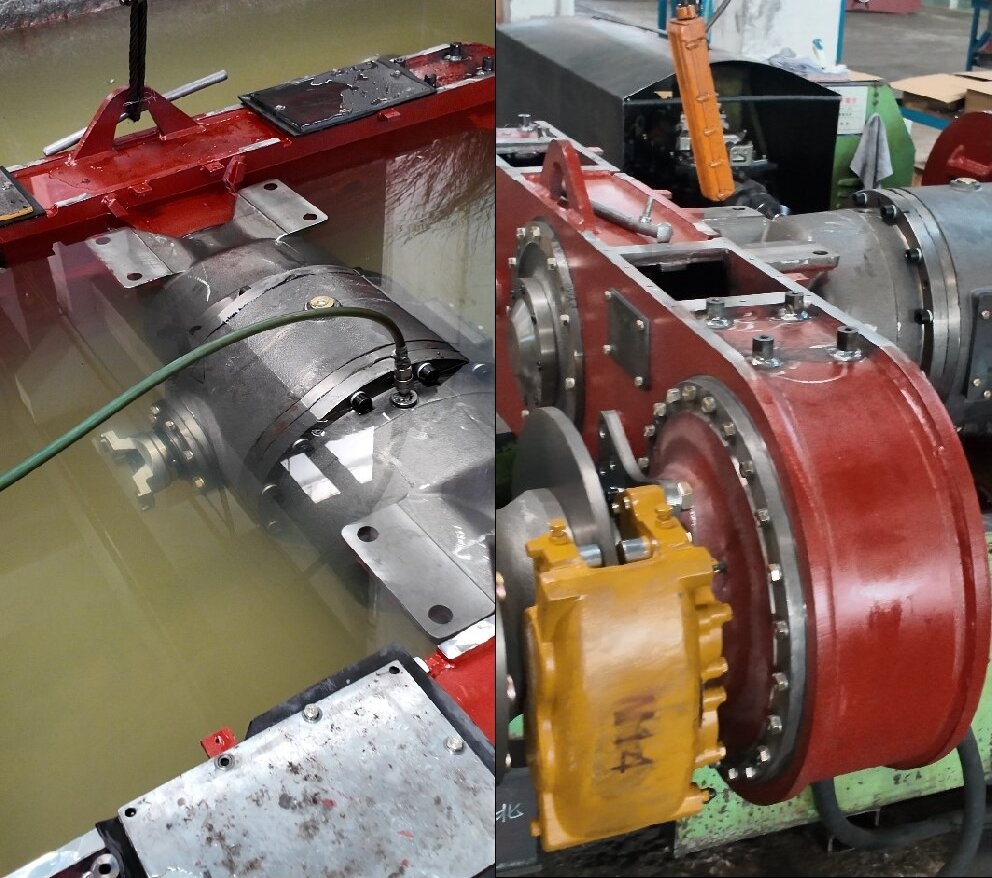

"Quality Is Life" is our core manufacturing principle. We implement a full-process quality control system covering raw material procurement, production, and finished product inspection. Strict ISO quality management and multiple international certifications are maintained throughout. Every drive axle undergoes multiple inspection procedures before delivery to ensure zero defects and provide customers with durable products. Factory Testing Includes:Bench fatigue testing、Sealing performance inspections、Noise and vibration analysis.

Global Services, a Trusted Partner

Shandong Lutong not only holds a significant position in the domestic market but also exports overseas. We have established a comprehensive after-sales service system offering rapid response and technical support to ensure customer peace of mind.

Continuous Innovation, Leading the Industry Future

To meet evolving market demands, Shandong Lutong continuously invests in R&D, exploring new materials and processes to enhance the intelligence and energy efficiency of drive axles. We collaborate with renowned universities and research institutions to advance industry technology.

Choosing Shandong Lutong means choosing expertise and trust! Whether in product quality, technological innovation, or service support, we are committed to providing optimal solutions. Visit our official website or contact our sales team for more product details!