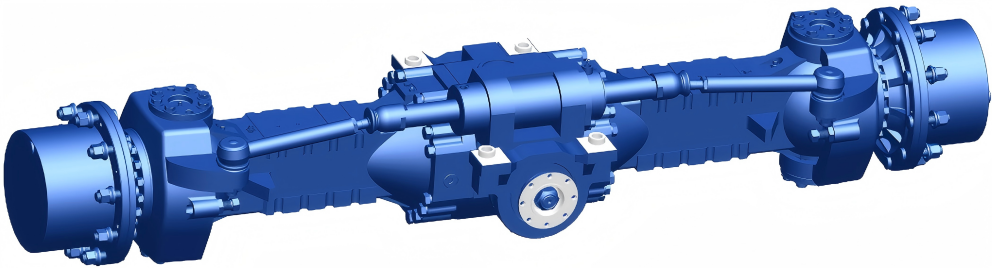

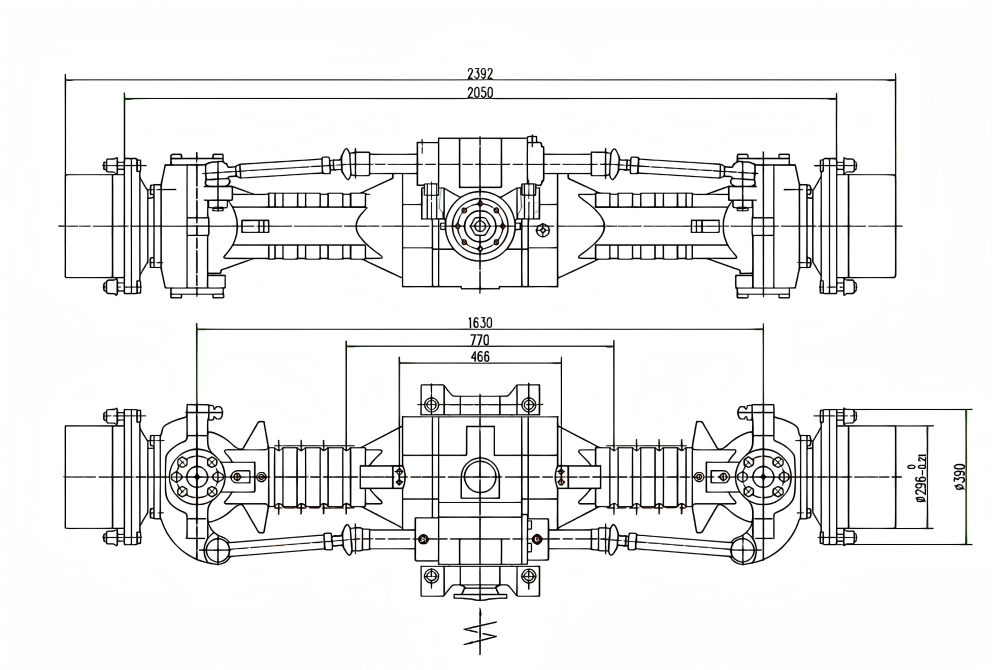

Drill Jumbo Axle

1. The primary reduction stage employs Gleason spiral bevel gears, delivering high transmission efficiency and effectively minimizing operational noise.

2. An "NGW type" planetary reduction configuration is implemented at the wheel end, featuring a compact design and optimized structural layout.

3. The braking system utilizes disc brake calipers, providing substantial braking torque to ensure stable and reliable braking performance.

4. Hydraulic power-assisted steering integration results in smooth operation and enhanced maneuverability.

5. The integral cast steel axle housing offers robust heavy-duty load capacity and high rigidity.

6. This axle is typically equipped on 14-16 ton rock drilling vehicles.

Introduction:

Designed for 14-16 ton rock drilling vehicles, this equipment delivers superior performance. The main reduction utilizes Gleason spiral bevel gears for efficient and quiet power transfer. The wheel end incorporates a compact, well-engineered "NGW type" planetary gear structure. Caliper disc brakes supply ample torque for stable stopping power. Hydraulic power-assisted steering ensures smooth maneuverability. The robust integral cast steel axle housing provides high load-bearing capacity and rigidity, making it ideal for demanding rock drilling applications.

Main technical parameters:

Total transmission Ratio | 14.77/16.91/22 |

Maximum Output torque | 50000N.m |

Dynamic load each axle | 13000Kg |

Braking torque (single side) | 21000N.m |

Braking oil pressure | 4Mpa |

Braking displacement | 45-128ml |

Angle of turning | 37°/30° |

Steering cylinder pressure | 14Mpa |

oil request for driving axle (API standard) | GL-5:85W/90 Gear oil(above -12 ℃) |

Brake and cylinder oil | L-HL46 hydraulic oil |