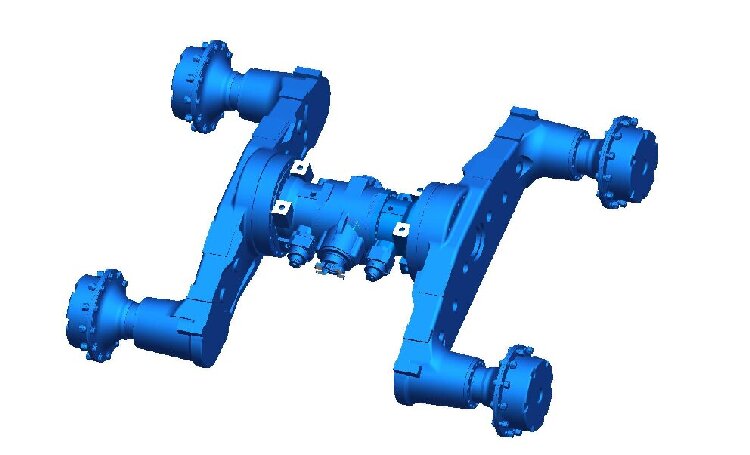

Bogie Axle

1. Wet braking

2. Four-stage large-speed ratio reduction structure

3. Quality benchmarking against internationally renowned brands

4. Products can be customized

5. Good price, fast delivery

1. Product overview of Bogie Axle

As the core component of the construction machinery transmission system, the bogie axle mainly undertakes the key functions of power transmission, load bearing and driving guidance. It is widely adapted to the application of various heavy engineering machinery, such as graders, mining dump trucks, etc. in complex operating scenarios. As the core supporting component of the transmission system of the logging collector, the bogie axle needs to accurately match the special needs of forest land operations. It must not only cope with the rugged terrain of the logging area and the soft ground covered by humus, but also carry instantaneous heavy loads during the dragging process of logs, but also resist the erosion of the transmission components by the humid environment between the forest and the dust of branches and leaves. In the round trip between the logging point and the material collection yard, the drive axle mainly undertakes three key functions: First, accurately transmit the power to the drive wheels, providing the equipment with sufficient traction to drag overweight logs; Second, dispersing the load through the optimized bridge structure to avoid local stress concentration caused by complex terrain; Third, combining with the material collection steering system, improve the steering flexibility of the equipment in dense forest areas, reduce scratches on surrounding trees, and ultimately ensure the efficiency and safety of material collection operations.

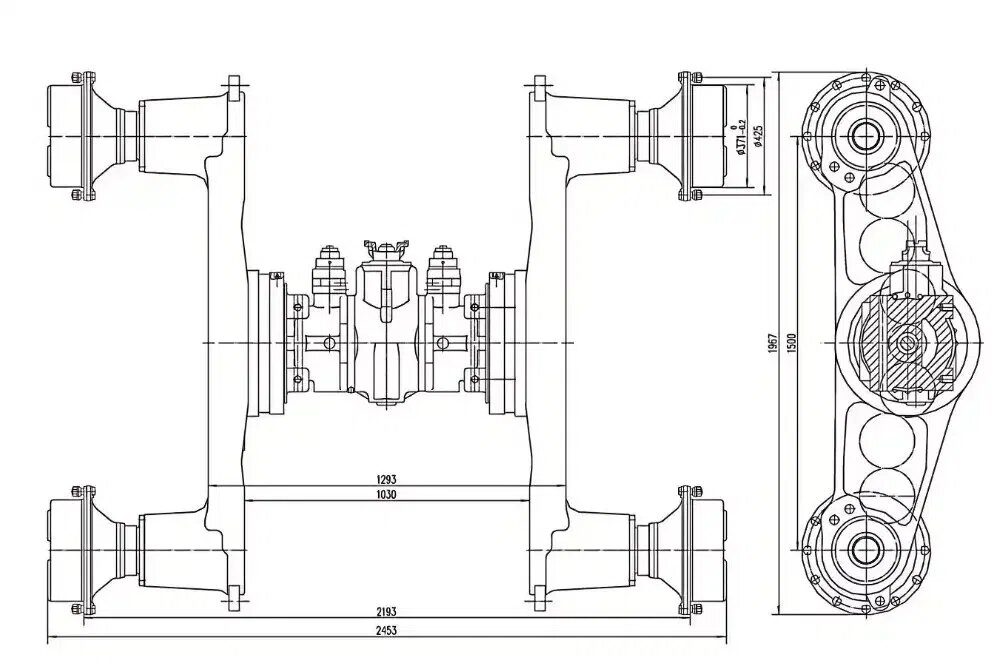

The total transmission ratio of the bogie axle is 25, the maximum input torque is 5600N.m, the maximum static bridge load is 26000Kg, and the maximum dynamic bridge load is 16000Kg. Our company can provide customized services, and can provide different parameter ratios to meet customer needs. It adopts a four-stage large-speed ratio reduction structure, with super-large speed ratio and torque amplification capabilities, adapts to extreme heavy-load conditions; dispersing the transmission load, improving system reliability and life; stable transmission efficiency, adapts to long-term continuous operation. The balancing box multi-stage gear transmission provides efficient power distribution to ensure the stability of multi-wheel drive; balances the load and speed difference, reduces wear of tires and transmission parts; has high impact resistance, and adapts to the reliability needs of harsh working conditions.

Main technical parameters:

Total transmission ratio | 25 |

Maximum input torque | 5600N.m |

Maximum input rotate speed | 2800r/min |

Rating load | 26000/16000Kg |

Brake oil pressure | 3MPa |

Differential lock oil pressure | 3MPa |

0il request for drive axle (API standard) | GL - 5:80W/90 Gear Oil (above - 26°C) |

0il request for brake | Cold region:L-HL46Wear resistant and low coagulation hydraulic oil |

2. Core advantages of bogie drive axle

Quality Assurance Dimension

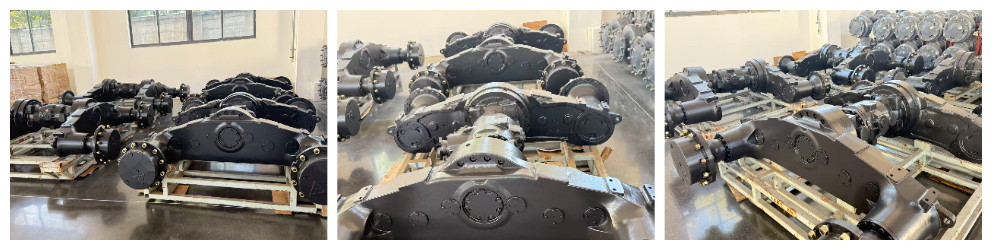

Raw materials that comply with mainstream international quality standards are adopted to establish a full-process inspection mechanism from blank processing to finished product assembly, covering dimensional accuracy inspection, load performance testing, fatigue resistance testing and other links, ensuring the durability of the product in a long-term heavy-load and high-frequency operating environment, reducing equipment downtime caused by component losses, and reducing later maintenance costs for users.

Technology R&D Dimension

Relying on the continuously iterative technology research and development system, focusing on the improvement of transmission efficiency and lightweight structure design, the mechanical properties of the axle shell are optimized through finite element analysis, and high-precision gear processing technology is used to reduce transmission noise and energy losses. At the same time, it has the technical adjustment ability to adapt to the power parameters of different models. It can provide personalized technical solutions according to the differences in engineering machinery operation scenarios to meet the equipment's diverse needs for traction and driving speed.

Sales Service Dimension

Build a sales network covering multiple regions and equipped with a professional technical sales team to provide customers with full-process services from product selection consultation to application scenario adaptation suggestions, avoiding selection deviations caused by information asymmetry. At the same time, a customer demand feedback mechanism is established to promptly respond to the market's new demand for product functions, and to adapt the procurement needs of customers of different sizes through flexible cooperation models (such as batch procurement, customized docking).

Logistics delivery dimension

Optimize the supply chain management system, establish a reasonable library storage and reserve mechanism, coordinate multi-channel logistics resources based on order priorities and the customer's location, realize rapid delivery response after order confirmation, and shorten the cycle from order placing orders to product delivery. In response to cross-regional and cross-border delivery needs, logistics routes and customs clearance processes are planned in advance to reduce the impact of project progress caused by logistics delays.

After-sales service dimension

Create a full-cycle after-sales service system, provide a 7×24-hour technical consultation hotline, and provide remote guidance and support for product installation and debugging and troubleshooting; for situations where on-site service is required, coordinate regional after-sales engineers to arrive at the site within the agreed time to solve problems efficiently. At the same time, we regularly provide customers with product maintenance suggestions to extend the service life of the product and improve customer experience.

Whether it is adapting to conventional infrastructure scenarios or meeting the challenges of special operating environments, bogie axle always provides core support for the efficient operation of construction machinery with reliable performance and flexible technical adaptability. Through strict control of quality, continuous iteration of technology, full-chain optimization of services, and accurate response to the industry's green and intelligent trends, we are committed to providing various customers with transmission solutions that meet their operating scenarios and development demands.

In the future, we will continue to keep up with the technological innovation and application expansion in the field of engineering machinery, continuously upgrade the environmental adaptability and functional value of the products. At the same time, with more efficient delivery efficiency and more complete after-sales support, we will establish long-term and stable cooperative relationships with customers, jointly respond to various challenges in the development of the industry, and help the continuous progress in the fields of infrastructure and special operations. If you have further demands for the selection, technical parameters or cooperation model of bogie drive axles, you can communicate with us through official channels at any time to obtain exclusive consulting services.