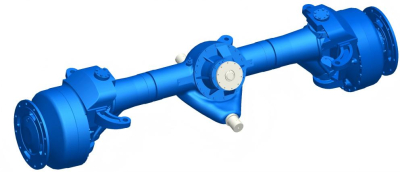

CY Series LHD Drive Axle: Sets Mining Equipment Quality Standard

Recently, the load haul dump drive axleseries independently developed by Shandong Lutong Heavy Industry Machinery Co., Ltd. has been officially launched into the international market, attracting widespread attention in the mining equipment industry. As a leading enterprise with over 30 years of experience in R&D and manufacturing of drive axles, Shandong Lutong has deeply empowered its products with high-performance mining machinery drive axle technologies based on its profound insight into mining working conditions and accumulated core technologies. By integrating a number of industry-leading core configurations and implementing strict full-process quality control, the company has created a highly efficient, safe and reliable equipment solution adapted to complex underground environments. This not only further improves the company’s product matrix of mining equipment, but also demonstrates the technological confidence and quality strength of Chinese mining equipment enterprises with its hardcore manufacturing capabilities.

Currently, the global mining industry is transforming towards intelligence, high efficiency and safety. As a core link of mining operations, underground mining performance is directly determined by the performance of its equipment. The underground mine environment is inherently complex and harsh: narrow roadway space limits equipment steering and passage; long-term wet and dusty road surfaces are prone to vehicle skidding and component wear; high-intensity continuous operations impose stringent requirements on equipment load capacity; meanwhile, the difficulty of equipment braking safety and fault diagnosis in enclosed environments is greatly increased. Amid this series of working condition challenges, the load haul dump drive axle, as the "power heart" and "walking hub" of the LHD machine, its transmission efficiency, anti-skid performance, braking reliability and environmental adaptability directly determine the operation efficiency, running stability and service life of the whole machine, becoming a core indicator for measuring the product competitiveness of LHD machines.

With years of deep cultivation in the drive axle field, Shandong Lutong has accumulated rich technical experience and a large number of independent patent achievements in R&D and manufacturing of mining machinery drive axles through continuous research on mining working conditions and technical breakthroughs. Relying on this core technical advantage, the company has deeply integrated drive axle R&D experience with the overall design of LHD machines, and achieved precise breakthroughs targeting the core pain points of underground operations. The final developed CY series load haul dump drive axlehas realized comprehensive upgrades in key dimensions such as power transmission, anti-skid braking and environmental adaptability, accurately matching the stringent requirements of underground mining, and providing a new choice for mining enterprises to solve the industry problems of low operation efficiency, frequent equipment failures and high safety risks.

In terms of core power transmission and anti-skid performance, the CY series load haul dump drive axleis equipped with an industry-leading No-spin limited-slip differential. This core configuration fundamentally solves the skidding problem on wet and muddy underground road surfaces, serving as a key support for ensuring continuous equipment operation. According to the technical team of Shandong Lutong, this No-spin limited-slip differential adopts an advanced mechanical locking structure, which can achieve 100% automatic locking function and accurately respond to complex road conditions without manual intervention. When the vehicle travels on muddy road sections or uneven roadways and a single wheel skids, the differential can complete the locking action in an instant, accurately transmitting all power torque to the wheel with adhesion. Even in extreme cases where one side of the wheel is suspended, it can still ensure the vehicle obtains sufficient traction to continue driving, completely avoiding the operation interruption problem of traditional LHD machines caused by skidding.

Compared with traditional differentials, the No-spin limited-slip differential also has a significant maintenance-free advantage. Its internal structure has been precisely optimized, requiring no special lubricants or regular disassembly and adjustment, which can adapt to the long-term continuous operation needs in underground environments, greatly reducing equipment maintenance costs and downtime for inspection and repair. Taking a large-scale underground mine as an example, the average monthly downtime of traditional LHD machines caused by skidding failures during operation in wet roadways is 8-10 hours, while the CY Series products equipped with this anti-skid differential can reduce such failure downtime to less than 1 hour, improving operation continuity by more than 80% and significantly enhancing mine mining efficiency. The application of this core technology enables the CY Series products to have super strong trafficability and operation stability in complex roadway environments, becoming an important equipment guarantee for mining enterprises to increase production capacity.

Safety is the primary prerequisite for underground operations, and also the core consideration of Shandong Lutong in developing the CY series load haul dump drive axle. To fully ensure underground operation safety, Shandong Lutong has equipped the CY Series products with Posi-stop spring-applied hydraulically-released wet brakes. This brake adopts an integrated design, integrating service braking and parking braking functions into one, achieving efficient and safe protection, and completely solving the problems of complex structure and multiple fault points of the traditional LHD machine braking system.

The high humidity, heavy mud and water, and heavy dust characteristics of the underground operation environment are one of the main causes of LHD machine drive axle failures. Targeting this core pain point, the CY series load haul dump drive axlespecially adopts a wheel-end floating oil seal structure, creating a highly efficient and reliable sealing protection system, and greatly improving the product’s adaptability to wet environments. The wheel-end floating oil seal consists of two floating rings with cemented carbide sealing surfaces and elastic elements. Through the preload of the elastic elements, the two sealing surfaces are closely fitted to form a double sealing protection, which can effectively prevent impurities such as mud, water, dust and coal cinder from entering the wheel-end transmission mechanism, fundamentally avoiding wear, jamming and other failures of key transmission components such as gears and bearings caused by impurity intrusion.

Through a large number of simulated working condition tests and verifications, the load haul dump drive axleequipped with this sealing structure has shown that after 3,000 hours of simulated operation in wet environments, the wear amount of wheel-end transmission components is only 15% of that of the traditional sealing structure, and the failure rate of the drive axle is reduced by more than 60% year-on-year. Even under extreme working conditions of long-term wetness and heavy dust, the drive axle can still maintain excellent transmission efficiency, effectively reducing the number of equipment downtime for maintenance, and significantly lowering the operation and maintenance costs for mining enterprises. The application of this structural design fully reflects Shandong Lutong’s R&D philosophy oriented to user needs, accurately solving the equipment application pain points of mining enterprises in complex environments.

The stable and reliable product quality stems from the strict control of every detail. In the whole R&D and production process of the CY series load haul dump drive axle, Shandong Lutong has always adhered to the principle of "quality first". From component selection and structural design to production and processing, every link implements strict quality standards. In terms of core component selection, the company insists on choosing internationally renowned brand products to ensure product reliability and service life from the source. Whether it is the core gears and high-precision bearings of the drive axle, or the key valve groups and seals of the hydraulic system, all have passed multiple rounds of review processes such as strict supplier selection, sample testing and batch verification, ensuring that every component meets international mining equipment industry standards and fundamentally eliminating equipment failures caused by component quality problems.

At the structural design level, the CY series load haul dump drive axleadopts an integral cast steel axle housing design. Compared with the traditional welded axle housing, the integral cast steel axle housing is formed by one-time casting, avoiding defects such as air holes and cracks generated during the welding process, and has stronger rigidity and impact resistance. Professional test data shows that the impact resistance of the integral cast steel axle housing is increased by more than 40% compared with the welded axle housing, which can easily cope with high-intensity load impacts such as frequent stone collisions and road bumps in underground operations, effectively extending the service life of the drive axle. Meanwhile, the drive axle adopts a two-stage reduction transmission design. After precise dynamic calculation and multiple rounds of optimization by Shandong Lutong’s technical team, the transmission efficiency is stably maintained at an excellent range of 92%-95%, ensuring strong power output while minimizing energy loss and achieving high-efficiency and energy-saving operation.

The successful launch of the CY series load haul dump drive axleis not only an important expansion of Shandong Lutong’s product matrix, but also a concentrated embodiment of the company’s production strength, technological R&D capability and quality control level. To ensure that product quality remains at the industry-leading level, Shandong Lutong has established a three-dimensional quality control system covering the whole process of R&D, production, testing and ex-factory delivery, forming a full-chain quality assurance model of "pre-event prevention, in-event control and post-event traceability".

Against the backdrop of the intelligent transformation of the global mining industry, Shandong Lutong will continue to be market demand-oriented and technological innovation-driven, continuously deepen the R&D of core drive axle technologies, constantly optimize product performance, and expand the product matrix of mining equipment. In the future, the company plans to further integrate intelligent technologies on the basis of the CY series load haul dump drive axle, develop intelligent LHD machines with functions such as remote monitoring, fault early warning and automatic navigation, and promote the development of mining equipment towards higher efficiency, higher safety and higher intelligence. Meanwhile, the company will continuously improve the global service network, enhance the response speed of overseas services, provide higher-quality equipment and services for the global mining industry, help mining enterprises achieve cost reduction, efficiency improvement and safe green mining, and promote the high-quality development of the mining equipment manufacturing industry.