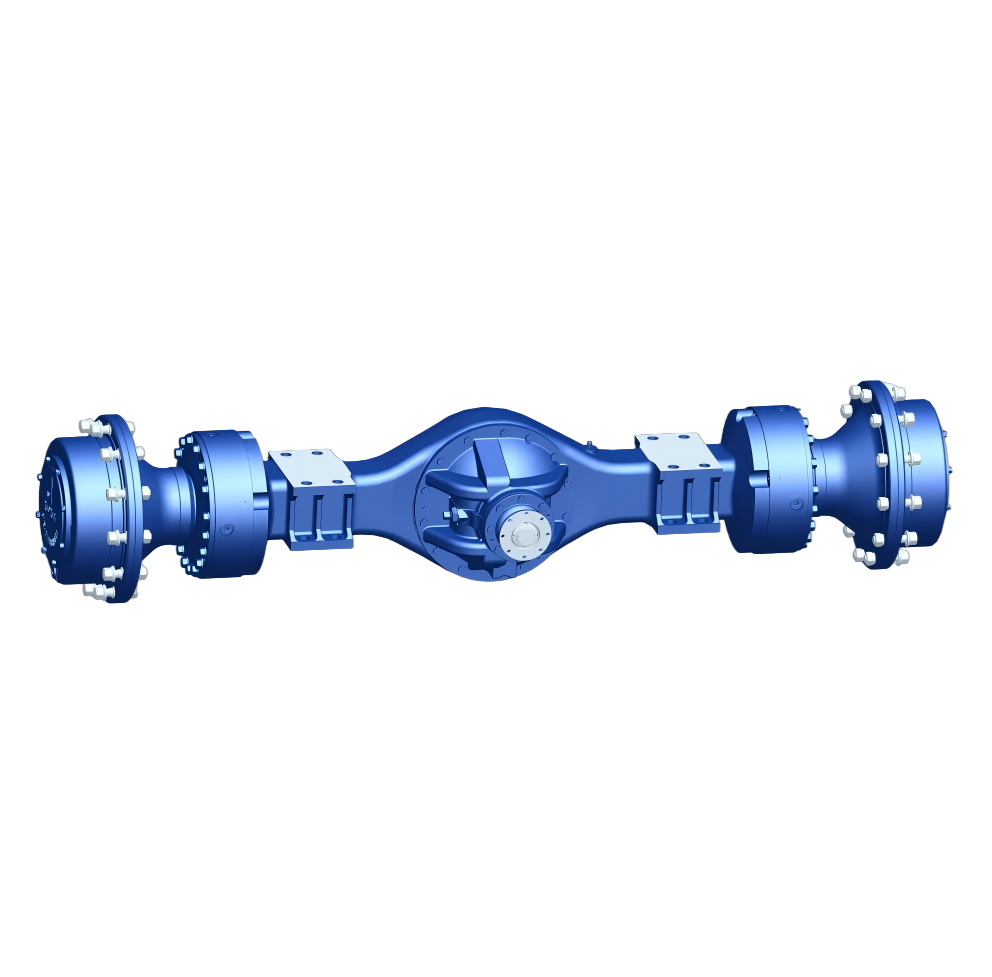

Loader Wet Brake Axle

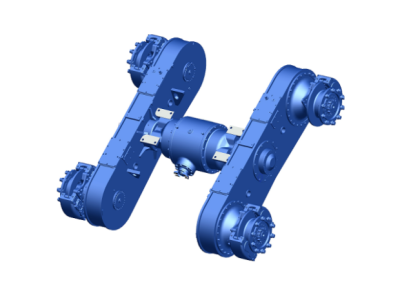

1. Wide transmission ratio range.

2. High power transmission efficiency and low operating noise.

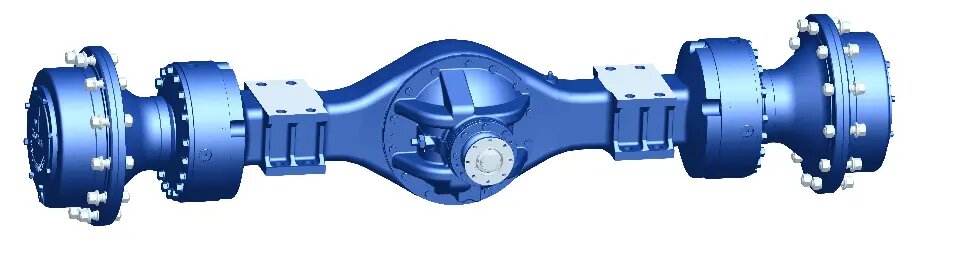

3. Reasonable and compact structure.

4. Stable braking performance, safe and reliable.

5. Consistent and reliable quality.

Introduction:

The wet brake drive axle comes with an advanced wet braking system, making it a top pick for safe and efficient operations.

Wet brake tech provides much stronger braking torque than dry brakes. Even in tough situations—like hauling heavy loads downhill or slamming on the brakes in an emergency—it lets you stop quickly, smoothly, and reliably. This goes a long way toward boosting operators’ confidence and getting more work done.

All the core braking parts are totally sealed inside the axle housing and soaked in cooling lubricant. This one-of-a-kind design does more than just offer great heat dissipation: it keeps performance steady even when you’re braking nonstop or at high intensity. What’s more, it completely gets rid of braking sparks. Even in high-risk spots with flammable or explosive materials—like underground coal mines—it stops braking from causing open flames entirely, giving key protection to workers and site safety.

On top of that, the oil-bath setup does a good job protecting the brake pads, which cuts down a lot on wear and thermal fade. That makes the braking system last longer, while also reducing how often you need to maintain it and the costs that come with upkeep.

Notice:

Our company's reliable wet brake drive axle can be used in extremely cold areas, but it must use low-temperature resistant gear oil.

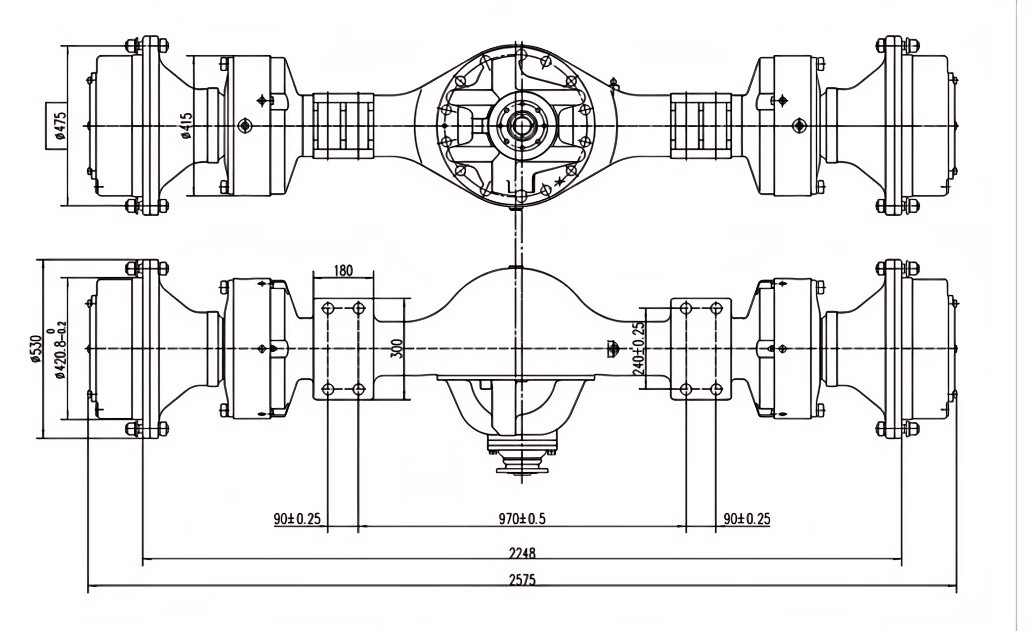

Main technical parameters:

Total transmission Ratio | 22.853 |

Maximum input torque | 5100N.m |

Load each axle | 27000Kg |

Braking oil pressure | 10MPa |

Braking capacity | 40-70ml |

Braking moment | 26000N.m |

Oil require for brake | L-HL46 Hydraulic oil |

Summary Comparison (vs. Dry Brake Axles)

Feature | Wet Brake Drive Axle | Dry Brake Drive Axle |

Braking Performance | Stable, excellent resistance to fade | Prone to fade, performance declines at high temperatures |

Service Life | Very long (multiple times that of dry brakes) | Relatively short, requires frequent replacement |

Maintenance Needs | Virtially maintenance-free, long intervals | Requires frequent cleaning and adjustment |

Environmental Resistance | Excellent, impervious to water, mud, dust | Poor, highly affected by the environment |

Initial Cost | Higher | Lower |

Safety | High, especially for heavy-duty and severe applications | Moderate, limited by operating conditions |

Comfort | Smooth braking, low noise | Harsh braking feel, higher noise |

We supply many OEMs and gain high trust in our products.

If you are looking for a reliable drive axle solution for the loader, whether you need to customize the adaptation solution for a specific model, understand the product quality certification details, or consult the supply cycle or batch procurement preferential policies, you are welcome to contact us through the official website online consultation, exclusive customer service phone number or corporate email address. We will respond quickly to demand with a professional team, combine the technical advantages of the product and improve after-sales service to provide you with the full process support from selection to delivery, helping your production and operation to promote efficiently. We look forward to working together with you for a win-win situation!