What is the Service Life of a Drive Axle? Shandong Lutong Has the Answer

In the operation of construction machinery, agricultural machinery, and mining machinery, the drive axle, as the core component transmitting power, has a service life that directly impacts equipment operating efficiency and maintenance costs. Many users are concerned: How long is the service life of a drive axle? Shandong Lutong, a high-tech enterprise deeply involved in the drive axle field, provides a detailed explanation of the key influencing factors based on years of industry experience and product development practice, revealing the durability code of high-quality engineering machinery drive axles.

Core Factors Influencing Drive Axle Service Life

There is no fixed standard for the service life of a drive axle. It is typically constrained by three main factors: product quality, operating environment, and maintenance practices, with significant variations across different scenarios:

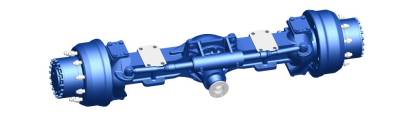

Product Quality is the Foundation: Inferior drive axles, due to insufficient material strength and low gear meshing precision, may have a service life of less than 5,000 hours. In contrast, high-quality engineering machinery drive axles, through stringent process control, can achieve a service life of 15,000 to 20,000 hours. Taking the loader drive axle as an example, Shandong Lutong uses high-strength alloy materials and robotic welding processes, enabling its products to maintain stable performance even under heavy-duty conditions.

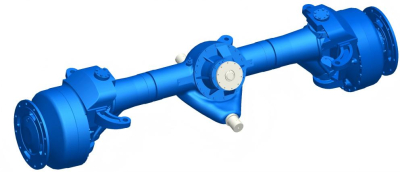

Operating Environment is Key: When a wheeled excavator drive axle operates in muddy sites, improper protection can easily lead to debris ingress and cause gear wear, potentially reducing its life by 30%. However, under standard operating conditions coupled with regular maintenance, its durability advantages can be fully realized.

Maintenance Practices Determine Longevity: Neglecting details such as gear oil changes and bearing preload adjustment can cause drive axle overheating, premature gear wear, and other issues. Statistics show that engineering machinery drive axles subjected to standard maintenance can have a service life over 60% longer than neglected products.

Shandong Lutong: Ensuring Drive Axle Durability with Robust Capabilities

As a core supplier to several renowned OEMs, Shandong Lutong provides strong support for drive axle service life through technological innovation and strict quality control:

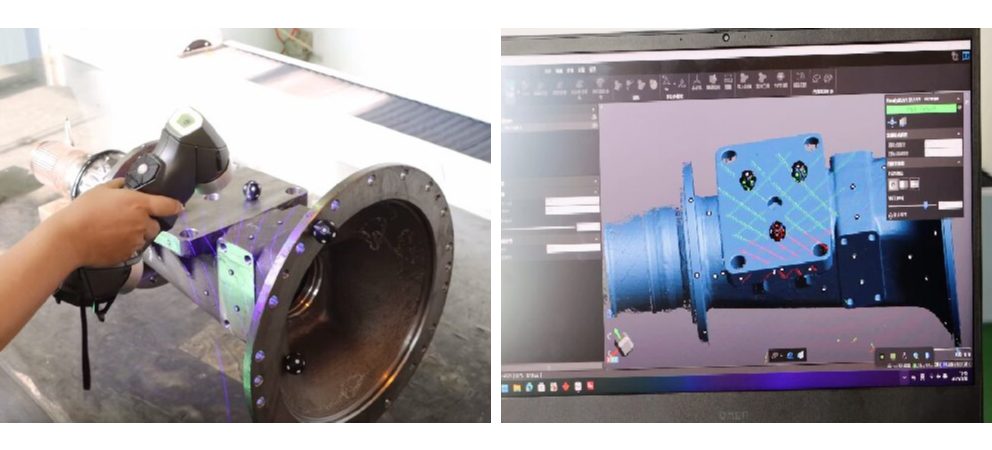

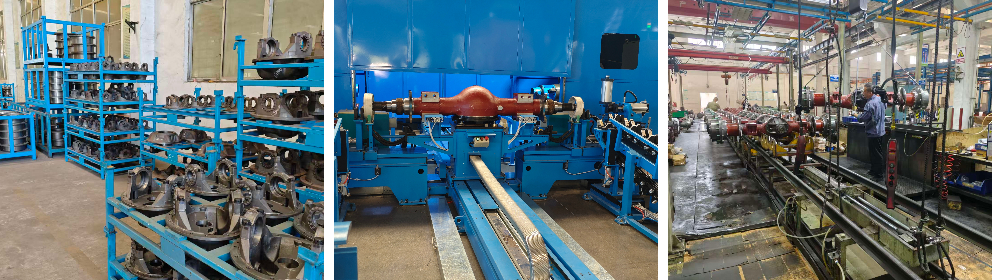

Intelligent Production Strengthens the Quality Foundation: The company has established a robotic drive axle welding production line, an intelligent planetary carrier production line, and specialized test systems. This enables fully automated control from component processing to finished product inspection, with an annual production capacity of 50,000 various drive axles. Product precision and stability far exceed industry standards.

Customized Solutions Meet Diverse Needs: Drive axle gear meshing clearance and bearing preload parameters are specifically optimized according to the operational characteristics of different equipment like loaders and wheeled excavators. For instance, the dedicated drive axle developed for mining loaders can adapt to continuous heavy-duty operation through a reinforced differential structure design.

OEM Recognition Attests to Strength: Relying on reliable product quality, Shandong Lutong has become a long-term partner for leading OEMs such as Sany, Shantui, Liugong, and Lovol. Its engineering machinery drive axle products are exported overseas and demonstrate excellent durability in complex working conditions.

Practical Recommendations for Extending Drive Axle Life

Choosing Shandong Lutong means more than just long service life; it means market-adapted assurance. We understand that for customers, 'durability' is not just a number, but also localized service and adaptation capabilities." Currently, we offer three key guarantees:

Customization Guarantee: Based on customer-provided parameters like load, slope, and temperature, we can complete drive axle solution design and sample production within 30 days.

Warranty Guarantee: Drive axles come with a 3000-hour warranty, including replacement of faulty components during the warranty period.

Transaction & After-sales Guarantee: We support flexible settlement and barter transactions, maintain a stock of over 5,000 common parts, and ensure rapid response.

Whether you are a mining company, agricultural machinery manufacturer, or construction machinery distributor, Shandong Lutong can provide drive axle solutions adapted to your local conditions, turning "long service life" from a number into stable operational assurance.

Based on industry experience, Shandong Lutong reminds users to follow three maintenance practices: First, refill with the specified type of gear oil according to specifications to prevent overheating and wear caused by poor lubrication. Second, regularly clean the breather to prevent excessive pressure build-up inside the axle housing that can lead to oil seal leaks. Third, promptly adjust gear meshing clearance to prevent gear tooth breakage caused by impact loads.

Choosing a high-quality drive axle is the prerequisite for extending service life. Shandong Lutong consistently adheres to the standard of "meeting the stringent demands of OEMs," continuously refining core product technologies like the loader drive axle and wheeled excavator drive axle, to provide global users with engineering machinery drive axle solutions that combine durability and cost-effectiveness.