Hangchi Plant Visit: Discussing Engineering Machinery Drive Axle Technology

A Powerful Alliance: Industry Leader's Visit Draws Attention, Charting a New Blueprint for Cooperation

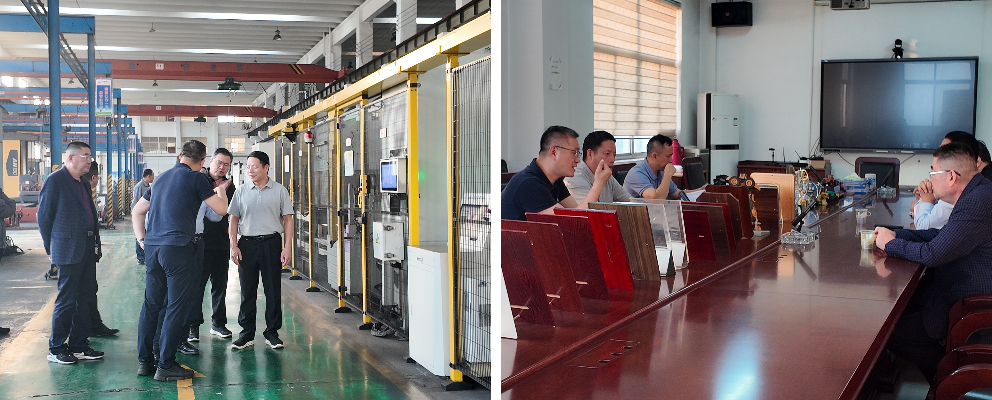

Recently, the Chairman of Hangzhou Advance Gearbox Group Co., Ltd., a leading domestic high-end transmission system enterprise, led a technical team to our company for an in-depth inspection and technical exchange. This high-level visit not only signifies industry authority's high recognition of our over three decades of dedication to the drive axle field but also marks a comprehensive upgrade in the strategic cooperation between both parties in the core components sector for engineering machinery. During the visit, the guests thoroughly toured our intelligent production workshop, national-level testing center, and R&D base, offering full affirmation of our achievements in core drive axle technology breakthroughs, intelligent manufacturing upgrades, and international market expansion.

The high-level nature and depth of this visit are rare in our company's recent external cooperation history. Hangzhou Gearbox Group, as a leading enterprise in China's gear transmission device sector, has products widely used in marine, engineering machinery, wind power, and other critical fields. This in-depth high-level exchange between our companies not only reflects the industry's recognition of our technical strength but also indicates potential for deep future cooperation in integrated transmission system solutions. During the two-day visit, technical personnel from both sides held multiple rounds of in-depth discussions on current drive axle technology trends, market demand shifts, and future cooperation directions.

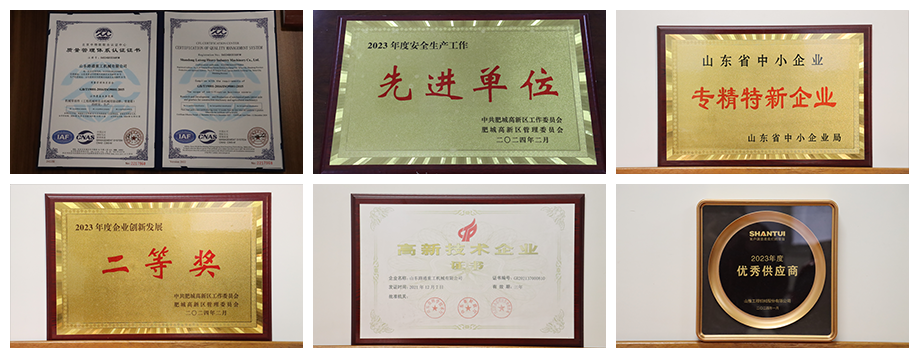

As a high-tech enterprise with over 30 years of professional R&D and manufacturing experience, our company has always focused on technological innovation and quality improvement for our series of engineering machinery drive axle products. Evolving from an initial single product line to a complete portfolio now covering diverse fields like engineering machinery, mining machinery, agricultural machinery, and forestry machinery, the company has grown into one of the domestic drive axle industry's enterprises with the most comprehensive product line and robust technical reserves. This visit by an industry leader further confirms our professional capability and influence in drive axle manufacturing, laying a solid foundation for deeper strategic cooperation in the future.

Strength Witnessed: Three Decades of Technical Accumulation Forges Industry Benchmark, Innovation Drives Development

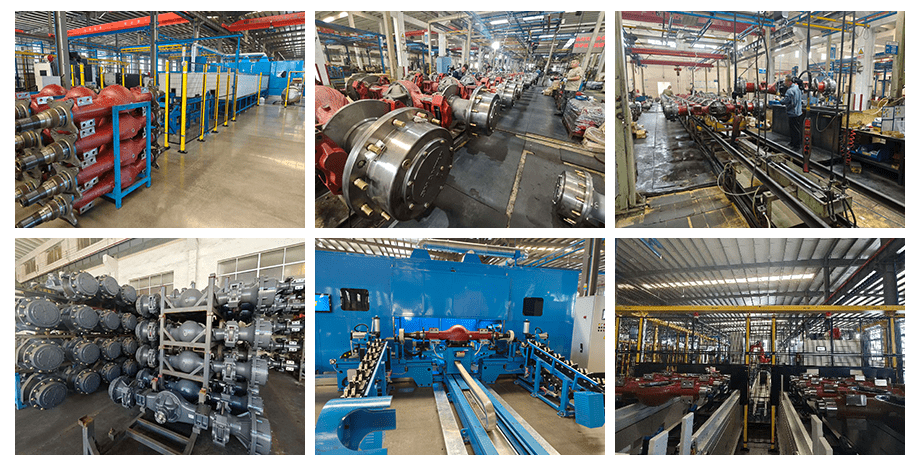

During the tour and exchange, the guests learned in detail about our comprehensive quality control system, spanning from raw material procurement to finished product delivery. In the precision machining workshop, dozens of advanced equipment from Germany and Japan are precisely processing core drive axle components, with robotic arms and high-precision machining centers working in coordination to ensure the machining accuracy of every drive axle part. In the 2,000-square-meter comprehensive laboratory, advanced equipment like ultrasonic flaw detectors and CMMs are subjecting products to rigorous verification.

Our company currently holds over 50 authorized patents, including more than 10 invention patents. The company invests 5% of its annual sales revenue into R&D, and the technical center brings together an R&D team of over 30 people, including one expert recipient of the State Council Special Allowance. This technical accumulation enables the company to provide comprehensive solutions for different clients, from structural design and gear optimization to control system integration.

Product Matrix: Diversified Layout Meets Global Demand, Technology Leads the Future

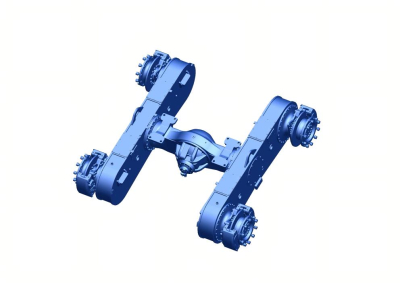

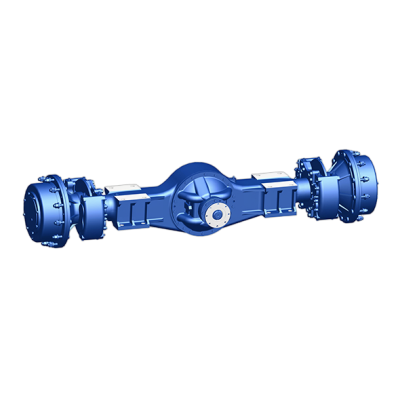

After more than three decades of development, our company has established a complete product matrix covering ten series and over a hundred models. In the engineering machinery sector, our wheel loader drive axle, transmission, and torque converter series products have ranked in the top three in domestic market share for five consecutive years, thanks to their high reliability and fuel economy. Among them, the 5-ton loader drive axle series, with its exceptional performance, has become an industry benchmark product, with cumulative sales exceeding 100,000 units.

The wide-body mining truck drive axle and LHD drive axle developed for mining machinery, known for their outstanding load capacity and durability, have successfully replaced multiple imported products. In agricultural machinery, the drive axle housing for high-horsepower tractors innovatively uses high-strength alloy steel, increasing fatigue life by over 10%. In forestry machinery, the log harvester drive axle assembly innovatively adopts a modular design, reducing maintenance costs by over 30%.

Particularly noteworthy is the company's pioneering layout in the new energy engineering machinery drive axle sector. The electric loader drive axle assembly developed for companies like Borelton has already entered batch production. This series features a main reducer with constant-depth teeth design and planetary gears using grinding processes, achieving a transmission efficiency increase of over 5% and a noise reduction of 20 dB compared to traditional drive axles. Concurrently, the company is actively advancing the R&D of new drive units like wheel-side drives, which will provide more advanced traction solutions for next-generation high-performance engineering machinery.

"We are not just a drive axle manufacturer; we are a solution provider for vehicle traction systems," emphasized the company's Technical Director when discussing the product portfolio. "From traditional mechanical drives to emerging electric drives, from standard products to deep customization, we are always committed to creating maximum value for our customers. Our goal is to become a globally leading traction system solution supplier."

Market Recognition: Chosen by Hundreds of Clients Domestically and Internationally, Quality Earns Trust

Relying on proven product quality and precise market positioning, our company's sales have achieved synchronous advancement in domestic and international markets, driven by this dual engine. In the domestic market, the company has established long-term, stable cooperative relationships with mainstream engineering machinery manufacturers like Sany Heavy Industry, LiuGong Group, Lonking Holdings, Xiamen XGMA Machinery, and Shantui Construction Machinery, being rated as an "Excellent Supplier" by many clients for consecutive years. The cooperation with Sany Heavy Industry is particularly profound; our company is not only a main drive axle supplier for Sany's loaders, excavators, and other products but also participates in the simultaneous development of multiple new Sany products.

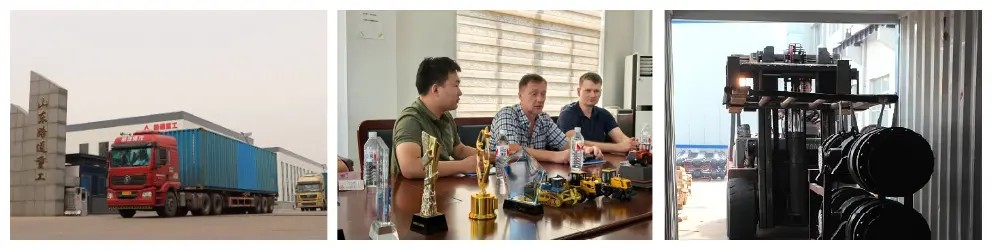

Regarding international expansion, the company seizes opportunities under the "Belt and Road" initiative, focusing on developing markets like Russia and Belarus, forming stable supply partnerships with renowned enterprises like PTZ, UMG, and AMKADOR. The motor grader drive axle custom-developed for the special needs of Russia's extreme cold conditions, after three winters of field verification, achieved an operational availability rate of 98.5%, receiving high praise from the customer. This drive axle, specifically designed for extreme cold environments, uses special low-temperature material formulas and sealing technology, enabling normal operation in extreme temperatures as low as -45°C, its performance fully surpassing similar European products.

Currently, the company's products are exported to over 30 countries and regions worldwide, with annual export revenue accounting for over 40% of total sales. To better serve international customers, the company has established offices and technical service teams in key markets like Russia and Belarus, providing localized after-sales support. This strategy of deeply cultivating markets has continuously enhanced the company's influence in the international arena.

The company's General Manager stated during the exchange: "We always adhere to a customer-demand-oriented approach. Every order is a commitment, and every product represents our reputation. It is this philosophy that has earned us the long-term trust of over 100 customers globally. In the future, we will continue to deepen the dual-drive model of 'Technology + Service' to provide customers with better products and services."

Cooperation Outlook: Creating a New Future for Core Components, Working Together for Mutual Development

This high-level visit by Hangzhou Advance Gearbox Group has laid a solid foundation for deep future cooperation between the two parties. During the seminar and exchange session, both sides held in-depth discussions on topics including the development of next-generation high-efficiency transmission systems, the application of intelligent manufacturing technology, and collaborative international market development, reaching intentions to cooperate in multiple areas.

Based on the consensus reached, the two parties will conduct deep cooperation in the following key areas: First, jointly tackling key technologies in transmission systems. Second, cooperating on market development, sharing customer resources, and providing integrated transmission system solutions. Finally, supply chain collaboration to reduce costs and enhance market competitiveness through joint procurement.

Our company's Chairman emphasized in the concluding remarks that the company will use this as an opportunity to further increase R&D and innovation investment, improve the global service system, and continuously enhance product competitiveness. In the next three years, the company plans to build a new smart factory, introduce internationally advanced production lines, increase annual drive axle production capacity by 50%, and simultaneously focus on breakthroughs in cutting-edge technologies like intelligent drive axles and electric drive axles, providing global customers with superior products and services.

"We firmly believe that through in-depth cooperation with outstanding enterprises in China's transmission field, we will undoubtedly create a new landscape for the development of China's core components," the Chairman expressed with confidence. "In this era full of opportunities and challenges, we will continue to uphold the core values of 'Innovation, Quality, Service,' advancing hand-in-hand with our partners to jointly propel the transformation from 'Made in China' to 'Created in China'."